Bearing for door or window header, Bearing at concrete wall – Georgia-Pacific GP Lam LVL User Manual

Page 8

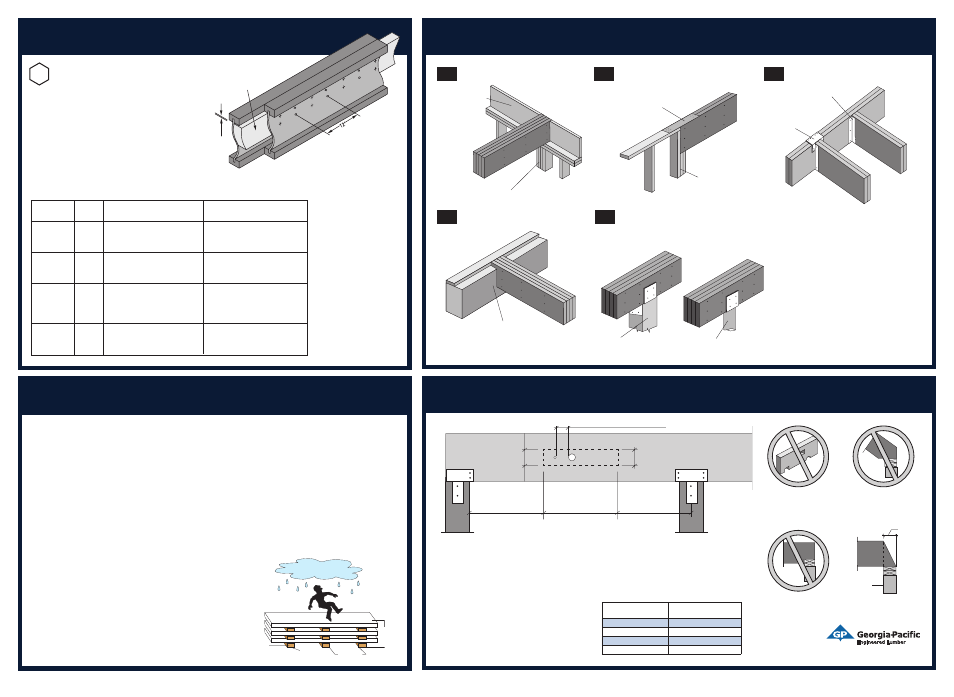

LvL allowable Holes

double I-Joists

LvL Storage, Handling, and Installation

bearing details

beam-to-beam Connection

bearing at wall

bearing at wood or Steel Column

Side plates are required for lateral restraint (if at

beam ends) and side plate connections may be

required for lateral load transfer.

bearing for door or

window Header

bearing area is extremely

critical and must be considered

for each application.

Multiple plies of GP Lam

®

LVL can be fastened

together to form a beam or header of the

required size, up to a maximum width of 7(

for 1

3

⁄

4

( and 3

1

⁄

2

( thick plies.

Engineered wood

rim blocking

(as shown) or

rim board

Built-up wood column

bearing at Concrete wall

Protect GP Lam

®

LVL from direct

contact with concrete or masonry per

local code requirements

Strap per code if top

plate is not continuous

over headers

Trimmers (see minimum

bearing lengths from

uniform load tables in

the Product Guide or

from software analysis)

Top-mount

hanger

Face-mount hanger

Wood column

with column cap

Steel column with

column cap

B1

B4

B5

B2

B3

2 x diameter of the largest hole (minimum)

Allowable Hole Zone

1

⁄

3

depth

1

⁄

3

depth

1

⁄

3

depth

1

⁄

3

span

1

⁄

3

span

1

⁄

3

span

Allowable Hole Zone

GENERAL NOTES

• The Allowable Hole Zone is suitable for uniformly

loaded beams using maximum loads for any

tables in the LVL User’s Guide. For other load

conditions or hole configurations, please contact

your GP Lam LVL representative.

• If more than one hole is to be cut in the beam,

the length of the uncut beam between holes

must be a minimum of twice the diameter of

the largest hole. No more than three holes are

allowed per span.

• Rectangular holes are not allowed.

• Holes in cantilevers require additional analysis.

• Required hole clearance and the effects of

beam deflection must be considered to prevent

problems with utilities that penetrate the holes.

• Maximum hole diameter is:

Do not cut, notch or drill

holes in GP Lam LVL except

as indicated in illustration for

allowable holes

Do not overhang seat cuts

on GP Lam LVL beams

from inside face of support

member

Confirm the required bearing area is provided by a

support that has adequate strength to carry the load.

Beam Depth

Maximum Round Hole

Diameter

3

1

⁄

2

(-7(

3

⁄

4

(

7

1

⁄

4

(-9

1

⁄

4

(

1

1

⁄

2

(

9

1

⁄

2

(-16(

2(

Deeper than 16(

3(

• GP Lam LVL should be stored and handled lying flat and

protected from the weather (sun and precipitation). Keep

covered until installed.

• Keep the LVL above ground to minimize the absorption of

ground moisture and allow air circulation.

• Re-cover unused products with bundle wrap. Repair

damage to bundle wrap with tape, more bundle wrap,

plastic or weatherproof covering.

• GP Lam LVL is only to be used in covered, dry use conditions

only (moisture content less than 16%). When in contact with

concrete or masonry, protect LVL per code.

• GP Lam LVL is produced without camber so either edge can

be used as the top (edgewise orientation).

• Nails installed in the narrow face of the LVL must be spaced

no closer than 3( (8d), 4( (10-12d, 16d sinker) and 8( (16d).

• Do not ship or install any damaged LVL.

• Deeper LVL depths have a greater potential for cupping and

damage from improper storage and handling.

• Except for cutting to length, LVL shall not be cut, drilled or

notched, except as shown in the design guide. Heel cuts

may be possible. Contact your GP Lam representative.

• 1

3

⁄

4

( plies that are deeper than 14( require multiple plies, or

must be full-depth blocked or full-depth restrained on both

sides of the ply at intervals not exceeding 24( o.c.

• Lateral support of LVL compression edge is required at

intervals not exceeding 24( o.c and at bearing locations.

• Do not splice LVL like dimension lumber. LVL ends must butt

over a support that provides the bearing required at each

end of the LVL.

• Fasteners, hangers or connectors for LVL framing either

from or into preservative or fire-retardant treated wood

must be hot-dip galvanized, or stainless steel, as required

by code and the type of treatment.

• Treating GP Lam LVL is not recommended, voids the

warranty and could present a safety and performance

concern.

CAUTION:

Wrap and LVL

may be slippery

when icy or wet

You’re purchasing a premium Georgia-Pacific product–protect your investment! Proper product care minimizes problems. Failure

to follow good procedures for storage, handling and installation could result in unsatisfactory performance and unsafe structures.

When handling Georgia-Pacific products use personal protective equipment for eyes, hands and feet.

Align stickers one

above the other

Hard, dry,

level surface

8*-0(

max.

10*-0(

max.

Do not

bevel-cut

beam

past

inside

face of

support

Inside

face

of support

Do not notch underside of

beam at bearing location

Georgia-Pacific, Wood I Beam, GP Lam and Fiberstrong are trademarks owned by or licensed to Georgia-Pacific Wood Products LLC. APA Rated, Sturd-I-Floor, APA Rim Board and APA Rim Board Plus are registered trademarks of APA-The Engineered Wood Association.

©2012 Georgia-Pacific Wood Products LLC. All rights reserved. GP-TM 8/12 Lit. Item #621579.

Joist

Joist

Regular Filler Blocking

Full-Depth Filler Blocking

Series

Depth

Use in detail F12

Use in details C4, F13, F14 & R7

9

1

⁄

2

9

2x6 2x6

11

7

⁄

8

9 2x6

2x8

149

2x8 2x10

9

1

⁄

2

9

2x6 +

3

⁄

8

9 OSB/Plywood

2x6 +

3

⁄

8

9 OSB/Plywood

11

7

⁄

8

9

2x6 +

3

⁄

8

9 OSB/Plywood

2x8 +

3

⁄

8

9 OSB/Plywood

149

2x8 +

3

⁄

8

9 OSB/Plywood

2x10 +

3

⁄

8

9 OSB/Plywood

9

1

⁄

2

9

2x6 +

5

⁄

8

9 OSB/Plywood

2x6 +

5

⁄

8

9 OSB/Plywood

11

7

⁄

8

9

2x6 +

5

⁄

8

9 OSB/Plywood

2x8 +

5

⁄

8

9 OSB/Plywood

149

2x8 +

5

⁄

8

9 OSB/Plywood

2x10 +

5

⁄

8

9 OSB/Plywood

169

2x8 +

5

⁄

8

9 OSB/Plywood

2x12 +

5

⁄

8

9 OSB/Plywood

11

7

⁄

8

9

(2) 2x6

(2) 2x8

149

(2) 2x8

(2) 2x10

169

(2) 2x8

(2) 2x12

GPI 20

GPI 40

GPI 65

WI 40

WI 60

GPI 90

WI 80

Filler blocking

1/89 gap

DOUBLE JOIST CONSTRUCTION

WITH FILLER

Note: Filler blocks and

fastening between joists

can be omitted when double

joists are loaded evenly

from above to the tops of

both joists, such as when a

parallel bearing wall is

directly centered over the

double joist.

1. Support back of web during nailing to prevent damage

to web-flange connection.

2. Leave

1

⁄

8

9 gap between top of filler blocking and bottom

of top flange.

3. Block solid between joists. For all applications except

cantilever reinforcement, filler need not be one continuous

length, but must extend the entire length of span. For double

I-joist cantilever reinforcement C4, filler must be one

continuous pieceextending the full length of the reinforcement.

4. Place joists together and nail from each side with 2 rows of 10d (16d for WI 80 and GPI 90)

nails at 129 o.c., clinched when possible. Stagger rows from opposite sides by 69.

F11

Installation Guide