Cantilevers for vertical building offsets, Concentrated wall load from above), Gp lam – Georgia-Pacific GP Lam LVL User Manual

Page 6: Lvl fastening requirements, Fastener clearances for multiple-ply members, Side loaded member

28-0

9

28-0

9 max.*

L

28-0

9

28-0

9 max.*

L

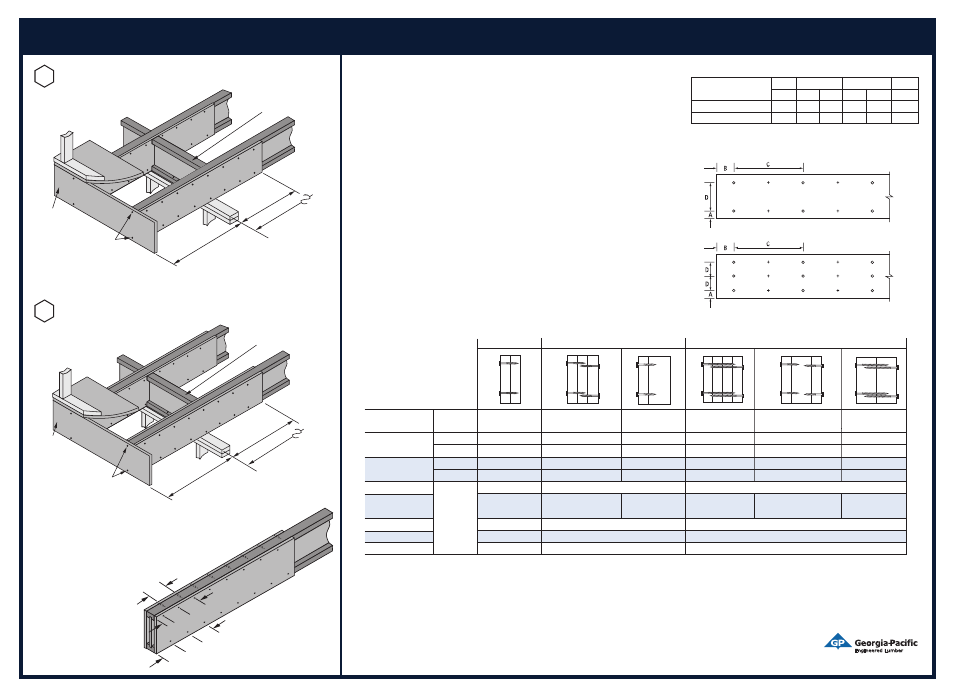

Cantilevers for vertical building offsets

(Concentrated wall Load from above)

GP Lam

®

LvL fastening requirements

3

1

⁄

2

9 Wide 5

1

⁄

4

9 Wide

79 Wide

Fastener Type

LVL Depth

2-Ply 1

3

⁄

4

9

3-Ply 1

3

⁄

4

9 1

3

⁄

4

9 + 3

1

⁄

2

9

4-Ply 1

3

⁄

4

9

2-Ply

2-Ply

1

3

⁄

4

9 + 3

1

⁄

2

9

3

1

⁄

2

9

10d (0.1289 x 39) 7

1

⁄

4

9≤d<149 3 rows @ 12” o.c. 3 rows @ 12” o.c. (ES)

3 rows @ 12” o.c.

-

3 rows @ 12” o.c. (ES) -

Nails d≥149

4 rows @ 12” o.c. 4 rows @ 12” o.c. (ES) 4 rows @ 12” o.c.

-

4 rows @ 12” o.c. (ES) -

16d (0.1629 x 3

1

⁄

2

9) 7

1

⁄

4

9≤d<149 2 rows @ 12” o.c. 2 rows @ 12” o.c. (ES)

2 rows @ 12” o.c.

-

2 rows @ 12” o.c. (ES) -

Nails

d≥149

3 rows @ 12” o.c. 3 rows @ 12” o.c. (ES) 3 rows @ 12” o.c.

-

3 rows @ 12” o.c. (ES) -

1

⁄

2

9 Through Bolts

2 rows @ 24” o.c. 2 rows @ 24” o.c.

2 rows @ 24” o.c.

SDS

1

⁄

4

9 x 3

1

⁄

2

9, WS35,

2 rows @ 24” o.c. 2 rows @ 24” o.c. (ES) 2 rows @ 24” o.c.

-

2 rows @ 24” o.c. (ES) -

3

3

⁄

8

9 TrussLok

SDS

1

⁄

4

9 x 69, WS6

d≥7

1

⁄

4

9

-

-

2 rows @ 24” o.c. (ES)

59 TrussLok

- 2 rows @ 24” o.c.

-

6

3

⁄

4

9 TrussLok

-

-

2 rows @ 24” o.c.

NOTES:

1. Minimum fastening requirements for depths less than 7

1

⁄

4

9 require special consideration. Please contact your technical representative.

2. Three general rules for staggering or offsetting for a certain fastener schedule: (1) if staggering or offsetting is not referenced, then none is required; (2) if staggering is referenced, then fasteners

installed in adjacent rows on the front side are to be staggered up to one-half the o.c. spacing, but maintaining the fastener clearances above; and (3) if “ES” is referenced, then the fastener

schedule must be repeated on each side, with the fasteners on the back side offset up to one-half the o.c. spacing of the front side (whether or not it is staggered).

GENERAL NOTES:

1. Confirm the adequacy of the beam (depth and width) for carrying the designated load.

2. Stress level for nail, bolt and screw values is 100%. Increases of 15% for snow loaded roof

conditions or 25% for non-snow roof conditions are permitted.

3. Top and bottom rows of fasteners should be as shown in the fastener clearances detail.

For staggered fastening patterns, the maximum end distance applies to all rows.

4. All fasteners must have the length fully embedded, but must not be over-driven, countersunk,

or over-tightened.

5. Bolt holes are to be

1

⁄

32

9 to

1

⁄

16

9 diameter larger than the bolts. Bolts must meet or exceed

ASTM A 307 or SAE J429 Grades 1 or 2. Every bolt must extend through the full width of the

member. Use washers not less than a standard cut washer under the head and nut meeting

ANSI B18.22.1.

6. 79 wide beams should only be side-loaded when loads are applied to both sides, when the

lesser side load plf is at least 25% of the opposite side, or when the beam is otherwise

restrained to minimize rotation.

7. For beam depths < 7

1

⁄

4

9, the maximum beam width must not exceed the beam depth and

all fasteners must be staggered up to one-half the required o.c. spacing. For depths ≥7

1

⁄

4

9,

the maximum beam thickness is 79.

8. Fastening recommendations are based on the 2005 National Design Specification for

Wood Construction (NDS) or fastener manufacturer’s design information.

9. SDS structural screws are produced by Simpson Strong-Tie Company, Inc., WS structural

screws are produced by United Steel Products Company, and TrussLok structural screws

are produced by FastenMaster-OMG, Inc. Structural screws must be installed per

manufacturer’s recommendations.

2 Rows “ES” (offset on back side)

3 Rows “ES” (offset on back side)

fastener Clearances for multiple-Ply members

Fastener

A B C D

Min. Min. Max. Min. Max. Min.

10d & 16d Nails

2( 2(

6( 4( 12( 3(

Bolts & Screws

2( 4( 12( 4( 24( 3(

minimum fastening

requirements for

top Loaded members

Spacings closer than those above may be acceptable, but require special

consideration. Contact your technical representative.

Side Loaded member

For side loaded members additional fasteners may be required. Please refer to the GP Engineered Lumber Product Guide.

59

69

69

69

29

69

69

DOUBLE REINFORCEMENT NAILING PATTERN

Note: FiberStrong rim board or 48/24 APA Rated sheathing (strength axis horizontal)

required both sides of joist. Depth must match full depth of joist.

Nail to joist flanges with 8d nails at 69 o.c.

Offset nailing on opposite side of flange to

avoid splitting.

23

⁄

32

9 APA

Rated sheathing

or FiberStrong

rim board

X-bridging or Wood I Beam

blocking

panels (see detail F2) required at

cantilevers and continuing for 48 on

each side of cantilevered area.

One 8d

nail at top and

bottom flange

* Cantilever length must not exceed

1/4 the adjacent span (L).

For allowable wall/roof loads on

cantilever, use cantilever table,

FASTBeam software or

contact Georgia-Pacific.

CANTILEVER, REINFORCED

Single Sheathing/Rim Board (Option I)

Note: FiberStrong rim board or 48/24 APA Rated sheathing (strength axis horizontal) required one

side of joist. Depth must match full depth of joist. Nail to joist flanges with 8d nails at 69 o.c.

23

⁄

32

9 APA

Rated sheathing

or FiberStrong

®

rim board

X-bridging or Wood I Beam

™

blocking panels (see detail F2)

required at cantilevers and

continuing for 48 on each

side of cantilevered area.

One 8d

nail at top and

bottom flange

* Cantilever length must

not exceed 1/4 the

adjacent span (L).

For allowable wall/roof loads on

cantilever, use cantilever table,

FASTBeam

®

software or

contact Georgia-Pacific.

C2

CANTILEVER, REINFORCED

Double Sheathing/Rim Board (Option II)

C3

Installation Guide