General Machine Products 89000 Cable Blowing Machine(Current) User Manual

Page 34

Page 34 of 64

General Machine Products Co., Inc.

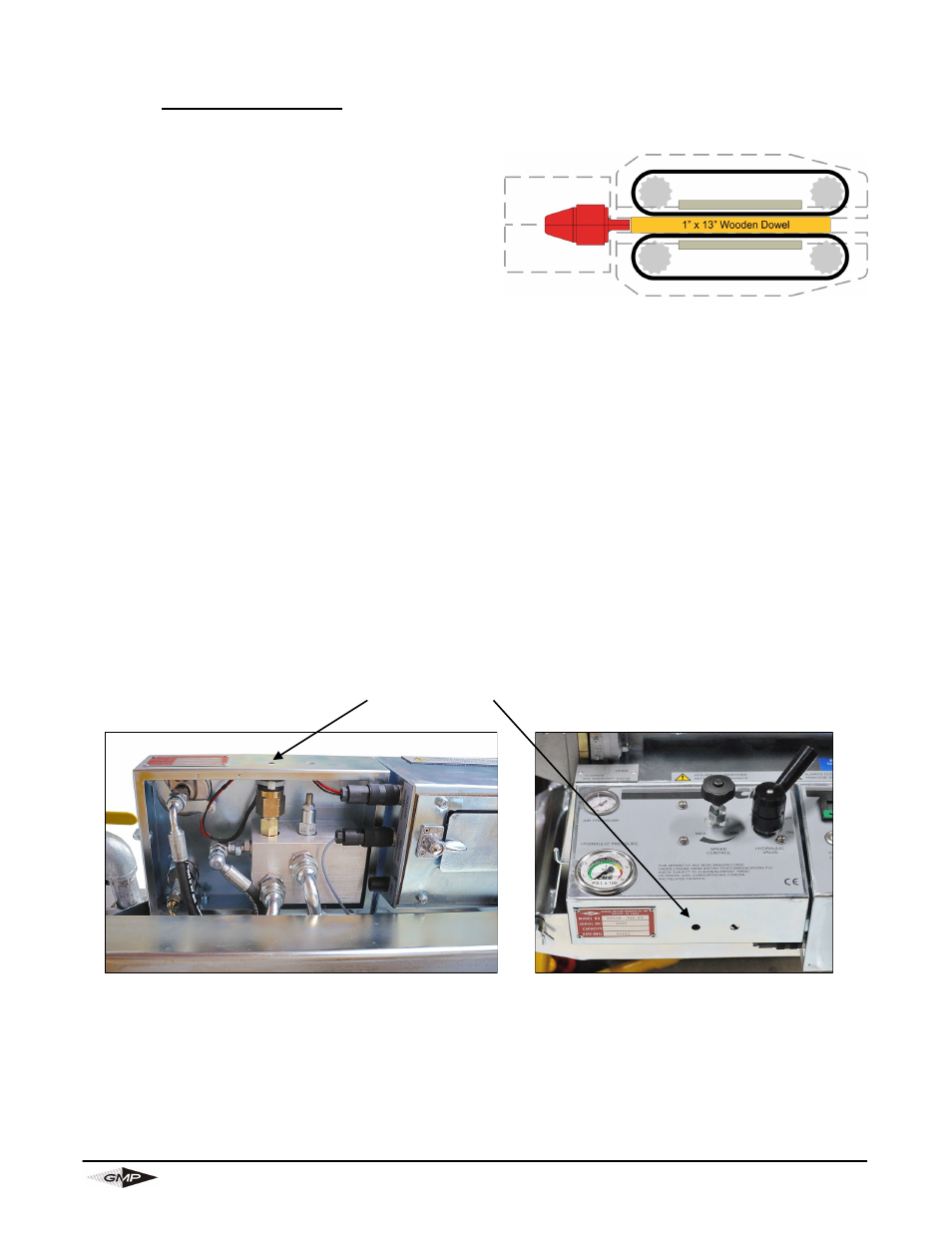

TO SET PRESSURE SWITCH FOR SMALL DIAMETER .47 INCH OD (12MM) OR UNDER

OR FLEXIBLE CABLE

Clamp a piece of 1” O.D. dowel/round bar x 13”

long between top and bottom housings so it butts

up to the air chamber mounted collets (in effect

placing the motors in stall mode). Note: The be-

low procedure will put the unit in a hydraulic by-

pass condition and will rapidly heat the oil. Try to

keep the time in bypass to a minimum as the

heated oil could change the readings

1. Connect the electric lead to the power pack and blowing machine.

2. Rotate the speed control knob fully counter-clockwise to “MIN”.

3. Press the on/off button (to turn the electric’s on).

4. Turn the pressure switch adjusting screw fully in (clockwise) using a 3/32 inch Allen key

through the hole in the front of the panel (see fig. 2).

5. Start the power pack.

6. Turn the hydraulic on/off valve to “on” position.

7. Turn the speed control knob towards “max” (clockwise) until the pressure gauge reads 870

psi (60 bar).

8. Turn the pressure switch adjusting screw slowly out (counter-clockwise) until the power

pack stops.

9. Turn the speed control knob to minimum (turned fully counter-clockwise).

10. After 5 seconds has elapsed restart the power pack and turn the speed control knob slow-

ly towards ”MAX” and note what pressure the power pack stops, repeat the procedure and

fine adjust the pressure switch adjusting screw until 870 psi (60 bar) is achieved.

When installation of cables of diameters .47inch (12mm) O.D. and above are re-

quired again, reset the pressure relief valve and pressure switch to:

Pressure relief valve 1600 psi (110 bar)

Pressure switch 1450 psi (100 bar)

Pressure Switch

Fig 2

Note: