EUCHNER HKB with pushbutton function User Manual

Page 3

Operating instructions for electronic handwheel HKB with pushbutton function

Correct use

The EUCHNER handwheel is a universal pulse gen-

erator for manual shaft positioning.

The handwheel is primarily used for positioning NC-

driven machine tools during set-up.

Handwheels are used as part of an overall higher-

level control system.

Their use, installation and operation are permissible

only in conformity with these Operating Instruc-

tions.

Correct use includes compliance with the relevant

requirements for installation and operation, in

particular

EN 60204, electrical equipment of machines

EN 12100, safety of machines, general design

principles

EN ISO 13849-1, safety-related parts of control

systems

Safety precautions

EUCHNER handwheels HKB meet the EMC protec-

tion requirements according to EN 61000-6-2 and

EN 61000-6-4.

Handwheels HKB must not be used for residential

applications, in business or commercial areas or

in small businesses.

Appropriate safety measures must be taken to

prevent a malfunction of the handwheel which

could cause danger to human beings or dam-

age to operating equipment.

Function

Depending on the type, 100 or 25 square wave puls-

es per revolution are available on the handwheel‘s

output to the user.

A second phase-shifted output allows the connected

control to detect the direction of movement.

The pulses are evaluated in the control.

The detent mechanism is magnetic and is therefore

totally wear-free.

Pushbutton function

By pressing the handwheel shaft in the axial direc-

tion, a pushbutton function is triggered. As a result

the digital output OUT is set. This output can be

evaluated using a downstream device. The hand-

wheel pulses are not affected by the pushbutton

function.

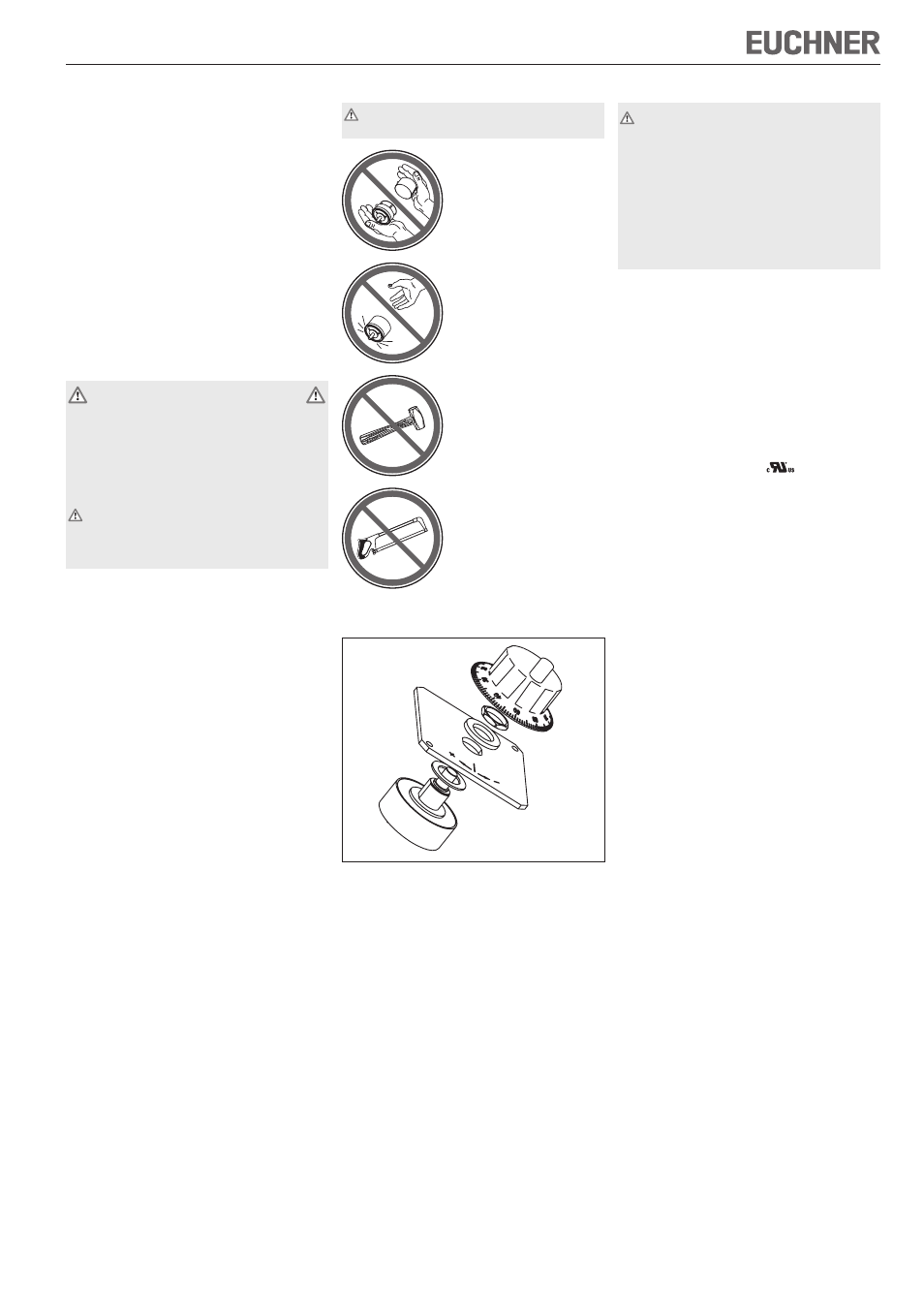

Assembly

The unit may only be assembled by authorised

personnel.

The handwheel is fitted by means of single-hole

bushing mounting (M15).

Fig. 1: Handwheel installation

Electrical connection

Electrical connection may only be performed by

authorised personnel trained in EMC with the

machine switched off and in de-energised

state.

The machine must be safeguarded against

reactivation.

If connected incorrectly, the handwheel

may be damaged.

Observe electrical characteristics and the pin

assignments (see technical data)

Always screen connecting leads.

Ground the screen at the end of the lead at a central

grounding point, e.g. in the distribution board or in

the control cabinet, over a large surface, with low

resistance and with low inductance.

Connect the screen on the handwheel using a tab

connector.

Do not install connecting leads in the immediate

vicinity of interference sources.

When installing connections, the operator must

ensure compliance with the EMC safety require-

ments.

Authorisation according to

: operation with

power supply of UL-class 2 only, housing type

UL-type 1.

Service and inspection

EUCHNER handwheels require no maintenance.

Handwheels may only be repaired by the manu-

facturer.

To clean the handwheels, only use solvent-free clean-

ing agents and a soft cloth.

Disclaimer of liability

The company does not accept liability regarding the

following cases:

if the unit is not used for its intended purpose

if the safety instructions are not followed

if the units are electrically connected by unautho-

rised personnel

if the units are tampered with

Instructions for counting the handwheel

pulses: Handwheel HKB

The following options are recommended for counting

the handwheel pulses:

suitable counter module

phase discriminator

Do not open the

handwheels!

Do not throw or drop the

handwheels!

Do not hit the handwheels!

Do not use tools on the

handwheels!