Correct use, Incorrect use, Function – EUCHNER SN 8 mm User Manual

Page 3: Switching elements / pin assignment, Installation, Protection against environmental effects, Electrical connection, Function test, Service and inspection, Technical data

Operating Instructions Precision Multiple Limit Switches GL, GS, SB, SN 8 mm

Correct use

Precision multiple limit switches are used for posi-

tioning and controlling machines and in industrial

installations.

Correct use includes compliance with the relevant

requirements for installation and operation, in

particular

EN 60204-1, Electrical equipment of machines

EN 1050, Safety of machinery. Principles for risk

assessment.

Incorrect use

Precision multiple limit switches with switching ele-

ment ES 552 und ES 614 (snap-action switching

elements not positively driven) must not be used

in safety circuits.

Function

Precision multiple limit switches possess several

switching elements arranged in a row.

The switching elements are actuated by means of

plungers. Different plunger types and trip dogs are

used depending on the application (operating point

accuracy and approach speed).

The plunger is actuated by trip dogs which are

mounted with an interference fit in trip rails.

The year of manufacture of the switch is indicated

in the production code.

Switching elements / pin assignment

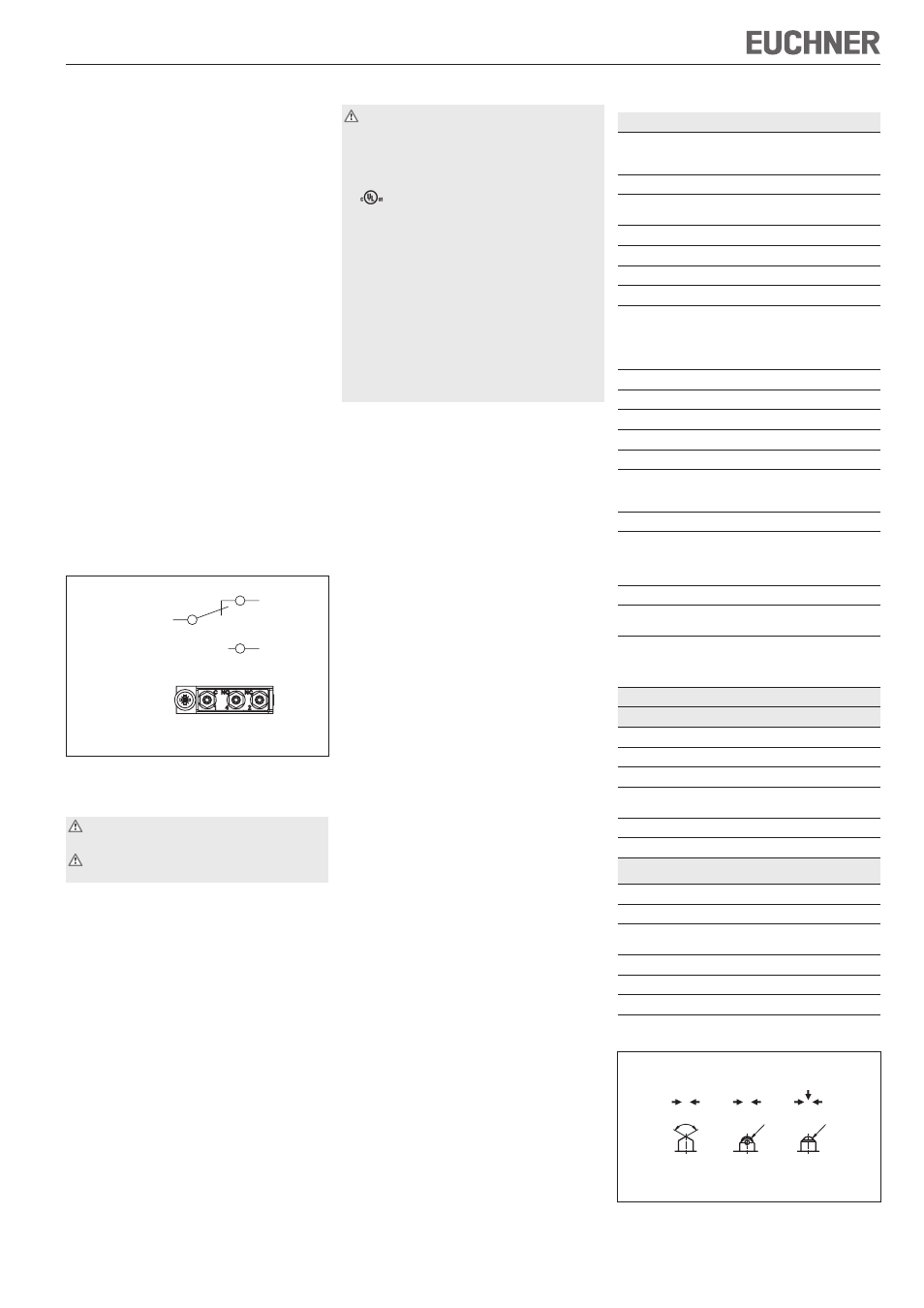

Fig. 1: Switching elements and pin assignment

Installation

This unit is to be assembled by authorized

personnel only.

Precision multiple limit switches must not be

used as an end stop.

Fit precision multiple limit switches so that

connection cables and plug connectors are not

damaged by moving parts of the machine

sealing is ensured on cable entry through the

base.

Protection against environmental effects

Safety venting valves are used to equalize the pres-

sure to protect against the pumping action of the

plunger. They must not be sealed with paint.

Mask plunger, plunger guide, safety venting valves

and rating plate during painting work!

Electrical connection

Electrical connection must be performed by

authorized personnel only.

The following applies for switches with UL ap-

proval:

For use and applications as per the requirements

of

, a class 2 power supply or a class 2

transformer according to UL1310 or UL1585

must be used.

Connection cables for precision multiple limit

switches installed at the place of use must be sepa-

rated from all moving and permanently installed

cables and un-insulated active elements of other

parts of the system which operate at a voltage of

over 150 V. A constant clearance of 50.8 mm must

be maintained. This does not apply if the moving

cables are equipped with suitable insulation materi-

als which possess an identical or higher dielectric

strength compared to the other relevant parts of

the system.

Open switch cover

Conductor cross-section 0.14 ... 1.0 mm²

For pin assignment see Figure 1

Fit suitable cable gland with captive O-ring

Seal cable carefully. Sealing ring must be matched

to the diameter of the cable

Tighten screws for connections to the switching

element to 0.2 Nm

Close switch cover and tighten cover screws to

0.5 Nm.

Function test

Mechanical function test

Actuate plunger and check the switching func-

tion.

Electrical function test

Check correct function.

Service and inspection

No servicing is required, but regular inspection

of the following is necessary to ensure trouble-free

long-term operation:

correct switching function

secure mounting of components

precise adjustment of trip dog in relation to multiple

limit switch

dirt and wear

sealing of cable entry

loose cable connections.

Exclusion of liability under the following

conditions:

if the unit is not used for its intended purpose

non-compliance with safety regulations

installation and electrical connection not per-

formed by authorized personnel

failure to perform functional checks.

Technical data

Parameter

Value

Housing material

Series

GL, GS

SB, SN

Sand-cast aluminum, anodized

Die-cast aluminum, anodized

Plunger material

Stainless steel

Degree of protection accord-

ing to IEC 60529

IP 67

Mech. operating cycles

30 x 10

6

Actuation frequency

≤ 200 min

-1

Ambient temperature

-5 ... +80 °C

Installation position

Any

Approach speed, max.

Plunger Chisel D

Roller R

(slide bearing)

Ball K

20 m/min

50 m/min

8 m/min

Approach speed, min.

0.01 m/min

Actuating force

≥ 15 N

Switching element

1 changeover contact

Switching principle

Snap-action switching element

Switching hysteresis max.

0.1 mm

Contact material

ES 552

ES 614

Silver

Gold cross cut contacts

Connection type

Screw terminal

Tightening torque

Screw terminal

(Hexagon socket head screw

AF 1.27 mm)

0.2 Nm

Conductor cross-section

0.14 ... 1.0 mm

2

Rated impulse

withstand voltage

U

imp

= 2.5 kV

Rated insulation voltage

with cable entry

with plug connector

U

i

= 250 V

U

i

= 50 V

Rated data for the switching elements

ES 552

Conv. thermal current I

th

6 A

Utilization category AC-15

230 V / 2 A

Utilization category DC-13

24 V / 2 A

Switching current, min. at

Switching current

10 mA

DC 24 V

Short circuit protection

6 A gG

Mechanical life

up to 10 x 10

6

operating cycles

ES 614

Conv. thermal current I

th

2 A

Utilization category DC-13

30 V / 1 A

Switching current, min. at

Switching current

1 mA

DC 5 V

Short circuit protection

2 A gG

Mechanical life

up to 10 x 10

6

operating cycles

Ideal application

1 mA; 5 V ... 0.3 A; 30 V

Figure 2: Plungers and approach directions

D

R

K

R4

R4

120

-5°

Preferred approach directions

ES 552

ES 614

1

2

4

1

4 (NO)

2 (NC)

(C)

Top view

on the switching element