EUCHNER GMOX-PR-22DS-C16 User Manual

Page 3

Translation of the original operating instructions

GMOX-PR-22DS-C16

Connecting instruction (abridged version)

AS-i 3.0 PROFIBUS Gateway with integrated

Safety Monitor for 2 AS-i networks

Notes on using these connecting and operating instructions

This connecting and operating instruction contains information regarding the proper

and effective use of the AS-i gateway.

See the manual „AS-i 3.0 PROFIBUS Gateway with integrated Safety Monitor for 2

AS-i networks“ and manual „ASIMON configuration software“ for detailed information.

Safety precautions and warnings are designated by the symbol

EUCHNER GmbH + Co. KG is not liable for damage resulting from improper use

of its equipment. Familiarity with these instructions constitutes part of the

knowledge required for proper use.

© Reprint and reproduction, in whole or in part, only with the explicit permission of:

EUCHNER GmbH + Co. KG

Kohlhammerstraße 16

*

D-70771 Leinfelden-Echterdingen

Tel. +49(0)711/7597-0

Fax +49(0)711/753316

Internet: http://www.euchner.de

This short description of the connection and operating instruction is a part of the

scope of delivery.

Application

The AS-i 3.0 PROFIBUS Gateway with integrated Safety Monitor for 2 AS-i networks

is a combination of a gateway with a safety monitor for 2 AS-i networks.

The safety unit works with two equal AS-i circuits and creates 16 stand-alone signals.

16 Safety at Work outputs can be controlled by it and up to two safe couple slaves can

be created.

The AS-i safety monitor is approved for safety applications up to Category 4/SIL 3.

Technical data

Safety characteristics

1).

Probability of a dangerous loss per hour.

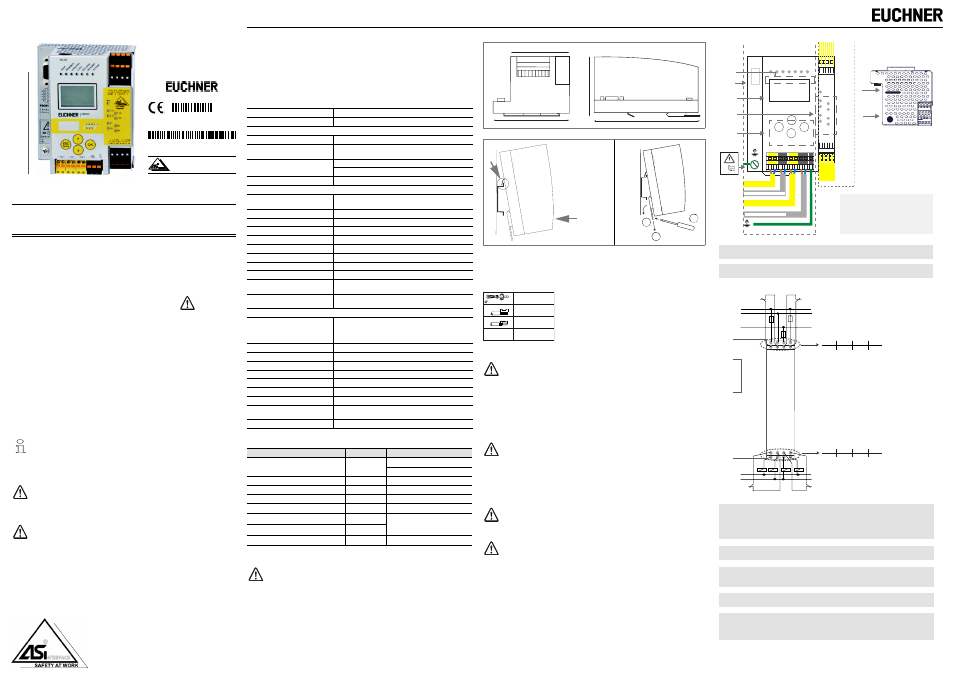

Dimensional drawing

Assembling

Disassembling

The AS-i gateway is mounted on 35 mm standard rails acc. to DIN EN 50 022.

For assembling, position the device on the upper edge of the standard rail and snap

it onto the bottom edge then.

Connection

Maintenance

The proper function of the AS-i safety monitor within the system to be secured, i.e. the

safe shutdown following the triggering of an assigned safe sensor or switch, is to be

checked at least annually by the safety officer.

Fig. 1: Connection overview gateway

Fig. 2: Connection overview safety monitor

Specified normal operation of the safety unit:

The safety monitor has been designed as a disconnecting protective de-

vice to safeguard danger areas on power-driven working materials. The

safe outputs put a machine in the safe state.

For connection and commissioning of the AS-i safety monitor the know-

ledge is assumend of the connecting und operating instructions as well

as operating instructions of ASIMON configuration and diagnostic soft-

ware.

Person protective function:

Safety monitor fulfills a person protective function. Inappropriate instal-

lation puts the function in risk! The manufacturer of the machine/plant at

that one the safety related devices is used is responsible for the correct

and safe total function of all single safety components! Depending on

the choice of safety components to be used the safety system as a who-

le may also be assigned to a lower safety category.

Id.

-No.: 10

4119 - I

ssue date: 20

11-8-

30

Subj

ect to

chan

ge with

out

p

rior no

tice

02102800000000001

GMOX-PR-22DS-C16

103374

AS-i Safety Monitor

Protocol:

PROFIBUS

Interface:

PROFIBUS

Euchner GmbH+Co.KG YoC: 2011

Kohlhammerstr. 16 70771 Leinfelden

AC-15, DC-13 3 A 30 V

Version NO.:

13915

Safety Version: V4.2

FA.0001

PROFIBUS interface

according to DIN 19 245 Part 3

Serial interface

RS 232

Safety monitor

Release circuits

4

Inputs:

4 x EDM/Start

EDM: contactor monitoring inputs

Start: start inputs

Outputs:

4 x output switching elements

relay outputs (output circuits 1 and 2)

semiconductor outputs (output circuits 3 and 4)

Card slot

chip card for storage of configuration data

Display

LCD

indication of slave addresses

and error messages

LED power

power on

LED PROFIBUS

PROFIBUS master recognized

LED config error

configuration error

LED U AS-i

AS-i voltage OK

LED AS-i active

AS-i normal operation active

LED prg enable

automatic address programming enabled

LED prj mode

configuration mode active

LED AUX

auxiliary power ON

4 x LEDs EDM/Start

state of inputs

LED off: open; LED on: closed

4 x LEDs output circuit

state of output switching element

LED off: open; LED on: closed

Electrical data

Operating current

master power supply, max. 300 mA out of AS-i circuit 1

(approx. 70 mA - 300 mA),

max. 300 mA out of AS-i circuit 2

(approx. 70 mA - 300 mA); in sum max. 370 mA

Operating voltage

30 V, 9 W

Voltage of insulation

500 V

Housing

AS-i master housing in stainless steel

Ambient operating temperature

0°C … +55°C

Storage temperature

-25°C … +85°C

Dimensions (L / B / H in mm)

120 / 100 / 96

Protection category IEC 60 529

IP20

Tolerable loading referring to im-

pacts and vibrations

according to EN 61 131-2

Weight

800 g

Characteristics

Value

Standard

Safety category

4

EN 954-1

EN 13 849-1:2008

Performance Level (PL)

e

EN 13 849-1:2008

Safety Integrity Level (SIL)

3

EN 61 508

Service life (TM) [year]

20

EN 13 849-1:2008

Maximal power-on time (month)

12

EN 61 508

PFD

9,25

.

10

-6

IEC 61 508 EN 62 061

PFH

D

1

5,36

.

10

-9

Max. reaction time [ms]

40

EN 61 508

In addition to the reaction time in the monitor, eventually reaction times

of other daisy-chained AS-i components have to be added too. See the

respective technical data for details.

Ensure appropiate installation:

Electrical installation is to be performed by trained expert personnel. Du-

ring installation care must be taken that supply and signal leads and also

the AS-i bus cable are laid separately from power cables. In the switch-

gear cabinet it must be ensured that appropriate spark-quenching

equipment is used with contactors. Where drive motors and brakes are

used, attention must be paid to the installation instructions in the corre-

sponding operating instructions. Please note that the maximum line

length of the AS-i bus cable is 100 m. Cables above that length require

the use of a suitable circuit extension.

It is essential to adhere to the prescribed fusing; this is the only way of

guaranteeing safe disconnection in the case of a fault.

This is to be performed by activating each safe AS-i slave at least once

per year and visually inspecting the switching behaviour of the output

circuits of the AS-i safety monitor.

The maximum switch-on time and total operating time depends on the

PFD value selected for the overall failure probability.

When the maximum switch-on time has been reached (three, six or twel-

ve months), the safety system must be checked to ensure that it is

functioning correctly by prompting the shutdown function.

When the total operating time has been reached (20 years), the device

must be checked at the manufacturer's factory to ensure that it is

functioning correctly.

120

96

100

85

[1]

[2]

1

2

3

0,8 Nm

7 LB.IN

5 ... 6 mm / PZ2

10

10

AWG

2 x 24 ...12

2 x (0,5 ... 1,5) mm

2

2 x (0,5 ... 1,5) mm

2

+

-

+

-

+

-

+ASI

1–

+

+ASI

2–

ASI

1 +PWR– (max. 8A)

ASI 2 +PWR– (max. 8A)

[2]

[1]

M4

5 mm max!

[3]

[4]

[5]

[6]

[1] - Chip card

[2] - RS 232 connection

[3] - LED status indicator

[4] - PROFIBUS connection

[5] - LCD display

[6] - Buttons for manual operation

+ASI 1– | +ASI 2–

Connection AS-i 1 circuit | Connection AS-i 2 circuit

ASI 1 +PWR– (max. 8 A) | ASI 2 +PWR– (max. 8 A)

Supply voltage AS-i circuit 1 | Supply voltage AS-i circuit 2

(top view)

[3]

K 3

24V_1

2.13

+

24 V

2.Y1

0 V

+

1.13

2.Y2

1.Y2

2.14

+

4.14

+

1.14

1.Y1

3.14

0V_2

24V_2

K 4

K2

K1

0V_1

0V_2

K2

K1 K3

K4

1.Y1 (EDM 1/Start 1), 2.Y1 (EDM 2/Start 2), 1.Y2 (EDM 3/Start 3),

2.Y2 (EDM 4/Start 4)

EDM- and start-inputs may not be connected with other potentials, but may only be con-

nected directly or over potential-free switches with + (for EDM/START).

Switching current static 4 mA at 24 V, dynamic 30 mA at 24 V (T=100 µs).

1.14, 2.14; 1.13, 2.13

Potential-free relay switches. Safety relay with a switch-set for feedback.

Max. contact load: 3 A AC-15 at 30 V, 3 A DC-13 at 30 V

+ (for EDM/Start)

Current supply output, supplied out of AS-i. It must not be connected with other poten-

zials, but it may be connected directly or via potential-free switches with the one of the

EDM- or start inputs. Voltage range 30 ... 15 V

DC

.

3.14, 4.14

Semiconductor outputs. Max. contact load: 0,5 A DC-13 at 30 V

0 V, 24 V

Supply for semiconductor outputs out of auxiliary 24 V DC