Operating instructions safety switches sgp, Inspection and service, Declaration of conformity – EUCHNER SGPxxx User Manual

Page 5: Technical data

Operating Instructions Safety Switches SGP...

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de [email protected]

Inspection and Service

If damage or wear is found, the complete switch

and actuator assembly must be replaced.

Replacement of individual parts or assemblies

is not permitted!

No servicing is required, but regular inspection of

the following is necessary to ensure trouble-free long-

term operation:

correct switching function

secure mounting of components

dirt and wear

sealing of cable entry

loose cable connections or plug connectors.

Safety switches must be exchanged completely after

2 million switching operations.

Note:The year of manufacture can be seen in the

bottom, right corner of the rating plate.

Exclusion of Liability under the Following

Conditions:

if the unit is not used for its intended purpose

non-compliance with safety regulations

installation and electrical connection not performed

by authorized personnel.

failure to perform functional checks.

Declaration of Conformity

See Annex 1 of the operating instructions.

Subject to technical modifications; no r

esponsibility is accepted for the accuracy of this information. © EUCHNER GmbH + Co. KG

097700-06-05/10 (translation of the original operating instructions)

34

34

42

42

22

22

12

12

12

12

22

22

42

42

34

34

14

22

22

42

42

34

34

21

22

14

13

11

12

22

21

22

12

14

22

21

11

13

21

41

42

34

33

33

41

21

11

22

21

11

12

12

11

21

22

11

21

41

33

33

34

42

41

14

13

21

22

13

21

41

33

33

34

42

41

1

2

3

4

5

6

4

5

6

7

8

11

9

3

2

1

10

PE

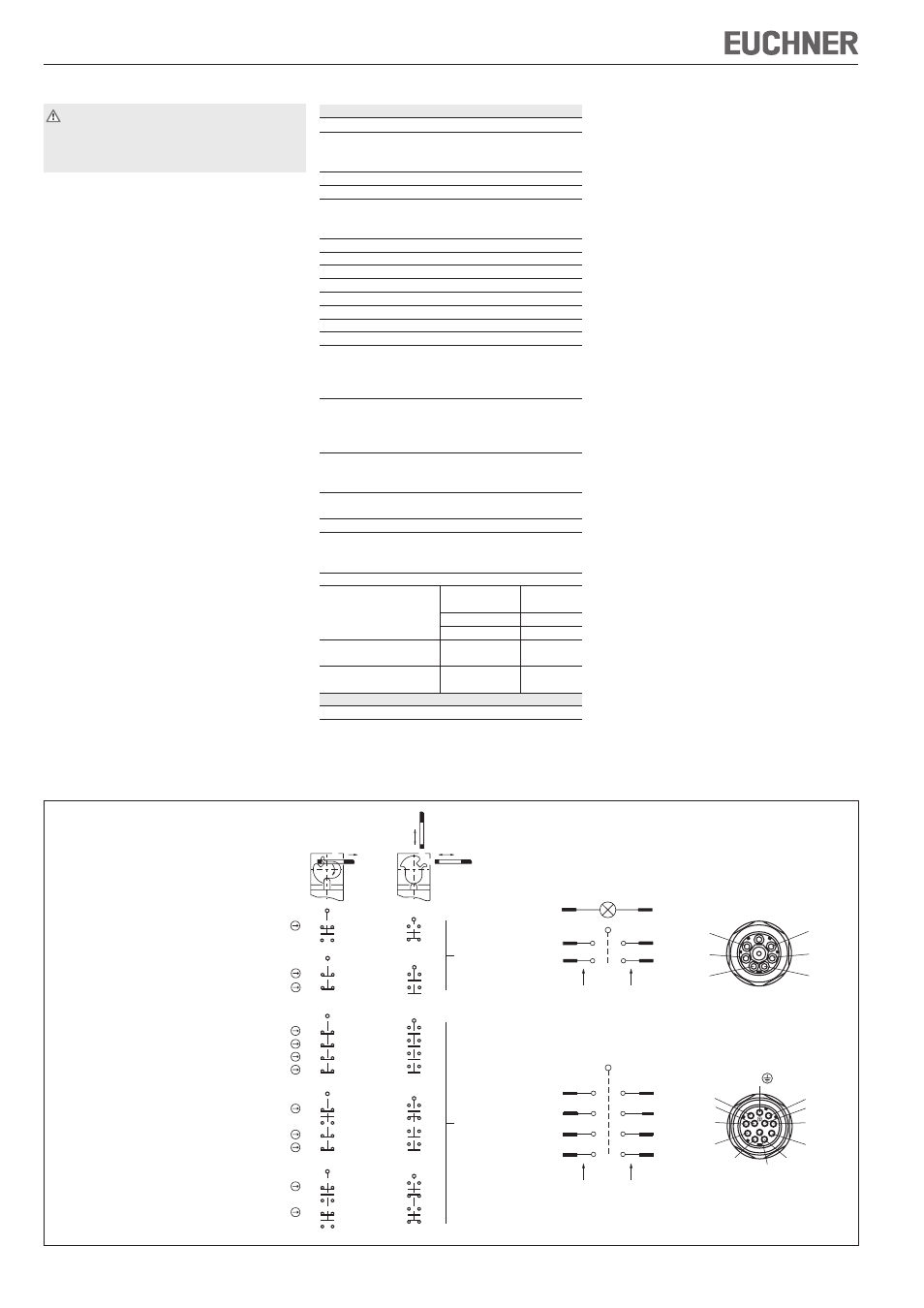

Version

Switching contacts

SGP.-528H...

1 NC contact +

1 NO contact

SGP.-538H...

2 NC contacts

SGP.-2121H...

4 NC contacts

SGP.-2131H...

3 NC contact +

1 NO contact

SGP.-3131H...

2 NC contact +

}2 NO contact

Door closed

Door open

Plug connector

SR6

Plug connector

SR11

2.

1

2.

2

3

4

1.

1.

6

5

Ordinal numbers of

switching elements

2.

1.

1.

2.

3.

3.

4.

4.

6

8

5

7

4

3

2

1

Ordinal numbers of

switching elements

Contact assignment with

plug connector

Connector

illustration

(view of safety switch

connection side)

(LED indicator with full wiring options, optional)

Figure 3: Switching elements and switching functions

Technical Data

Parameters

Value

Housing material

Reinforced thermoplastic

Degree of protection according to IEC 60529

SGP1...

IP67

SGP2...

IP65

Mech. Mechanical life

2x10

6

operations

Ambient temperature

-20 ... +80°C

Degree of contamination

(external, according ?to

3 (industrial)

EN 60947-1)

Installation position

Any

Approach speed, max.

20 m/min

Actuating force

25 N

Actuation frequency, max.

6700 / h

Extraction force

25 N

Retention force

10 N

Switching principle

Slow-action switching contact

Contact material

Silver alloy, gold flashed

Connection type

SGP1...

Screw terminal

SGP2...SR6

Plug connector SR6, 6-pin+PE

SGP2...SR11

Plug connector SR11, 11-pin+PE

Conductor cross-section (rigid/flexible)

SGP1...

0.34 ... 1.5 mm²

SGP2...SR6

0,5 ... 1.5 mm²

SGP2...SR11

0.5 mm²

Operating voltage for

L060

12 - 60 V

optional LED indicator

L110

110 V

(only SGP...528H/SGP...538H) L220

230 V

Switching voltage min.

12 V

at 10 mA

Switching current, min., at 24 V

1 mA

Short circuit protection

(control circuit fuse)

4 A gG

according to IEC 60269-1

Conv. thermal current I

th

4 A

Utilization category

SGP1.../SGP2...SR6

SGP2...SR11

according to EN 60947-5-1

AC-15

4 A 230 V

4 A 50 V

DC-13

4 A 24 V

4 A 24 V

Rated impulse

withstand voltage

U

imp

= 2.5 kV

U

imp

= 1.5 kV

Rated insulation

voltage

U

i

= 250 V

U

i

= 50 V

Reliability figures according to EN ISO 13849-1

B

10d

3 x 10

6