Enerpac BPR-Series User Manual

Page 9

9

6.0 MAINTENANCE

6.1 Press

1.

Remove P-51 hand pump handle when the press is not

in use.

2.

Keep work area and press bed free of dirt, chips and

unnecessary tools and fixtures.

3.

Periodically check the press frame to make sure that all

bolts are tight and frame parts are undamaged Replace

or properly repair damaged parts immediately.

4.

If the paint becomes badly chipped, the unit should be

repainted to prevent rusting and keep the frameʼs

appearance neat.

6.2 Pump

1.

Maintain proper oil level in all pumps. Use only Enerpac

hydraulic oil. Use of other fluids may damage the pump

and will void your Enerpac warranty

2.

Change the oil as recommended in the pump

instruction sheets.

3.

Keep pumps clean and free of debris.

4.

Do not obstruct air flow around the electric pump.

6.3 Air Removal

1.

With the pump positioned higher than the cylinder,

advance and retract the cylinder several times avoiding

pressure build-up. Air removal is complete when the

cylinder motion is smooth. Carefully read the

instructions included with the pump and cylinder for

detailed procedures of air removal.

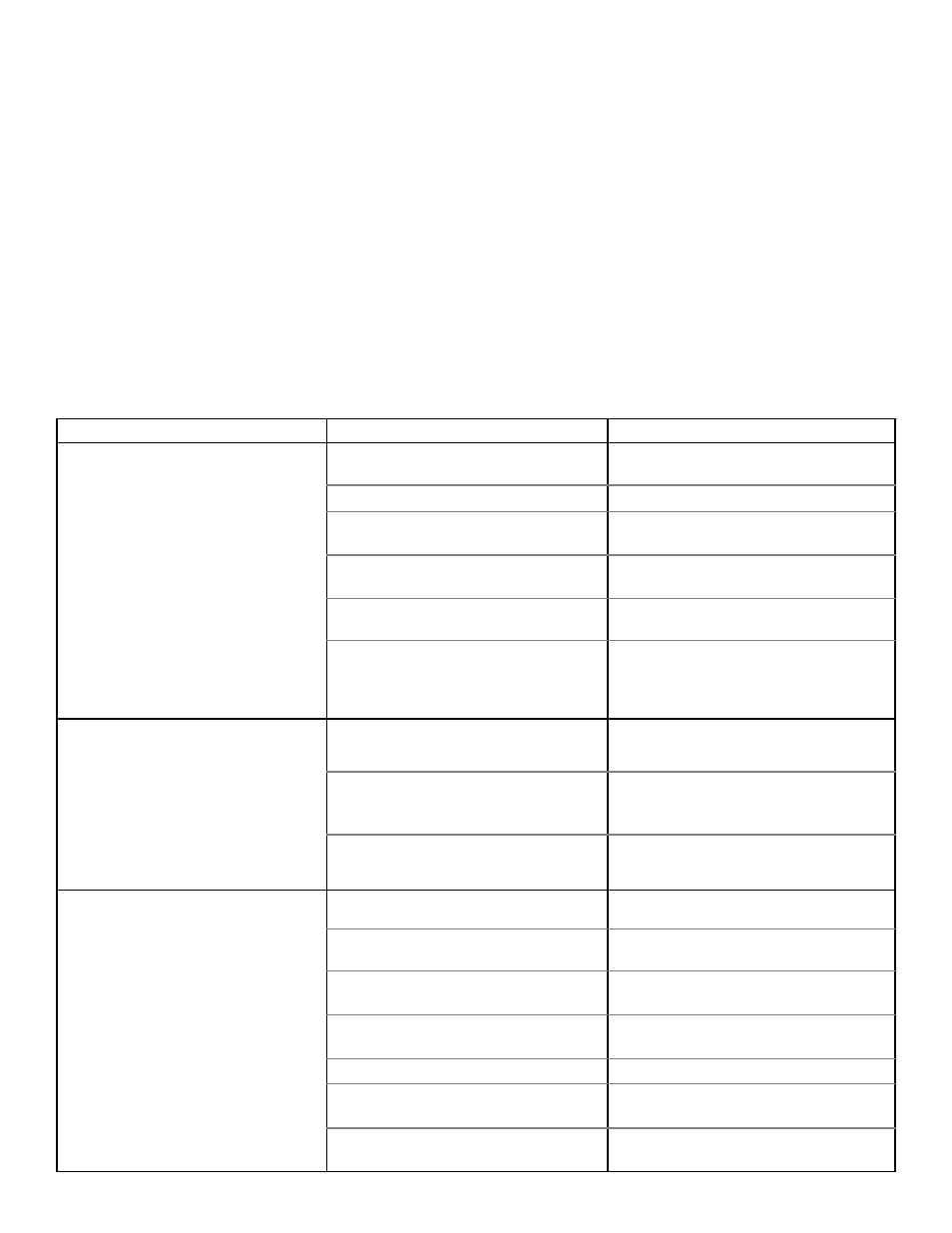

Problem

Cylinder does not advance,

advances slowly, or advances in

spurts.

Cylinder advances, but does not

hold pressure.

Cylinder does not retract, retract

part way, or retracts more slowly

than normal.

Possible Cause

Oil level in pump reservoir is low.

Pump release valve open.

Loose hydraulic coupler.

Load is too heavy.

Air trapped in system.

Cylinder plunger binding.

Leaking connection.

Leaking cylinder seals.

Internal leakage in pump.

Pump release valve closed.

Pump reservoir is over-filled.

Loose hydraulic coupler.

Air trapped in system.

Hose I.D. too narrow.

Cylinder retraction spring broken or

other cylinder damage.

Cylinder attachments are too heavy

for a single acting cylinder.

Solution

Add oil according to the pump

instructions.

Close pump release valve.

Check that all couplers are fully

tightened.

Do not attempt to lift more than

rated tonnage.

Remove air according to the

instructions on page 9, Sec. 6.3.

Check for damage to cylinder.

Have cylinder serviced by a qualified

hydraulic technician.

Check that all connections are tight

and leak free.

Locate leak(s) and have equipment

serviced by a qualified hydraulic

technician.

Have pump serviced by a qualified

hydraulic technician.

Open pump release valve.

Drain oil level to full mark. See

pump instructions for adding oil.

Check that all couplers are fully

tightened.

Remove air according to the

instructions on page 9, Sec. 6.3.

Use larger diameter hydraulic hose.

Have cylinder serviced by a qualified

hydraulic technician.

Use a double acting cylinder or

reduce the weight of the attachment.

7.0 TROUBLESHOOTING