Enerpac CT-604 User Manual

Page 2

2

4.0 INSTRUCTIONS

DANGER: Never attempt to relieve hydraulic

pressure by loosening a coupler. Trapped

hydraulic pressure can cause a loosened

coupler to dislodge unexpectedly with great force.

Serious personal injury or death will result if the

coupler becomes a projectile and strikes persons

working in the area.

WARNING!

Loosening a coupler may result

in an escape of high pressure oil that can

penetrate the skin. Serious personal injury or

death can result. Always use coupler bleed tool to

safely depressurize and remove couplers.

WARNING! Be sure that loads are supported

with blocking and cribbing before using bleed

tool. Actuator movement may occur when

hydraulic pressure is relieved. Serious personal injury

or death could occur if load shifts or drops.

WARNING! The CT-604 coupler bleed tool is

designed for a maximum hydraulic pressure

of 10,000 psi [700 bar]. Do not use the tool on

systems and components operating at higher

pressures.

Depressurize a hydraulically-locked coupler as

described in the following steps:

1. I f the hydraulic device is supporting a load, block

and crib the load as required, so that the load

will not shift or drop when hydraulic pressure is

relieved.

2. Check that the threads on the coupler half to be

depressurized are clean and in good condition.

Do not attempt to bleed a coupler if threads are

damaged.

3. Check that all threads on the bleed tool main body

and cap/bolt assemblies are clean and in good

condition. Do not use bleed tool if threads are

damaged.

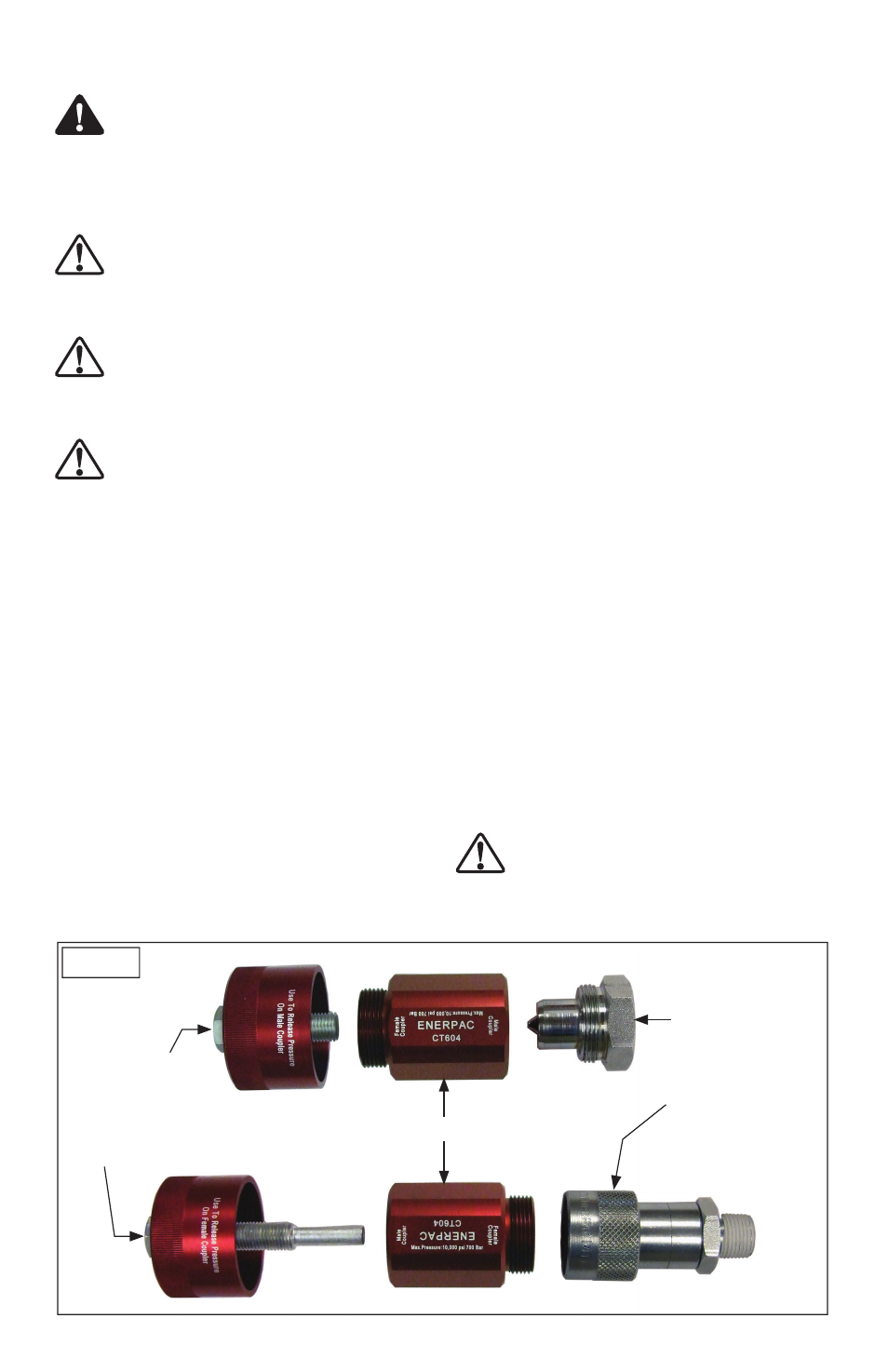

Note: Hand-tighten the bleed tool main body onto

the coupler half as described in steps 4 and 5. See

Figure 1, below.

Note: The bleed tool main body is marked “male

coupler” on one end and “female coupler” on the

other. Be sure to use the proper end.

4. If bleeding a male coupler half: Thread the bleed

tool main body onto the male coupler half and

tighten it hand-tight.

5. If bleeding a female coupler half: Thread the bleed

tool main body into the retaining collar of the

female coupler half. Tighten the retaining collar

hand-tight.

6. The bleed tool includes two cap/bolt assemblies

as shown in Figure 1, below. Be sure to use the

correct one:

• For MALE coupler halves, use the cap/bolt assem-

bly with the SHORT bolt.

• For FEMALE coupler halves, use the cap/bolt as-

sembly with the LONG bolt.

Note: Before proceeding, ensure that the cap is tight

on the bolt.

7. Thread the cap/bolt assembly into the bleed tool

main body. Slowly turn the cap/bolt assembly

clockwise until the coupler check ball opens and

hydraulic pressure is relieved. If necessary, use an

adjustable wrench on the bolt.

Note: When the cap/bolt assembly is tightened,

pressurized hydraulic oil will fl ow through the bleed

tool main body and into the cap. Allow any excess oil

to drain into a suitable container.

8. Remove coupler half, main body and cap/bolt

assembly from the hydraulic device (manifold,

cylinder, etc.) as a complete unit. Important: Keep

bleed tool parts installed on coupler while it is be-

ing loosened and removed.

9. Disassemble bleed tool components from the

coupler half. Clean bleed tool components and

store in provided container.

CAUTION: Discard the coupler half removed

in the previous steps. Never attempt to repair

or reuse a worn or damaged coupler!

Long Cap/Bolt Assy

(use with female coupler halves)

Short Cap/Bolt Assy

(use with male

coupler halves)

Main Body

Male Coupler Half

Female Coupler Half

Figure 1