Enerpac SOH-Series User Manual

Page 2

2

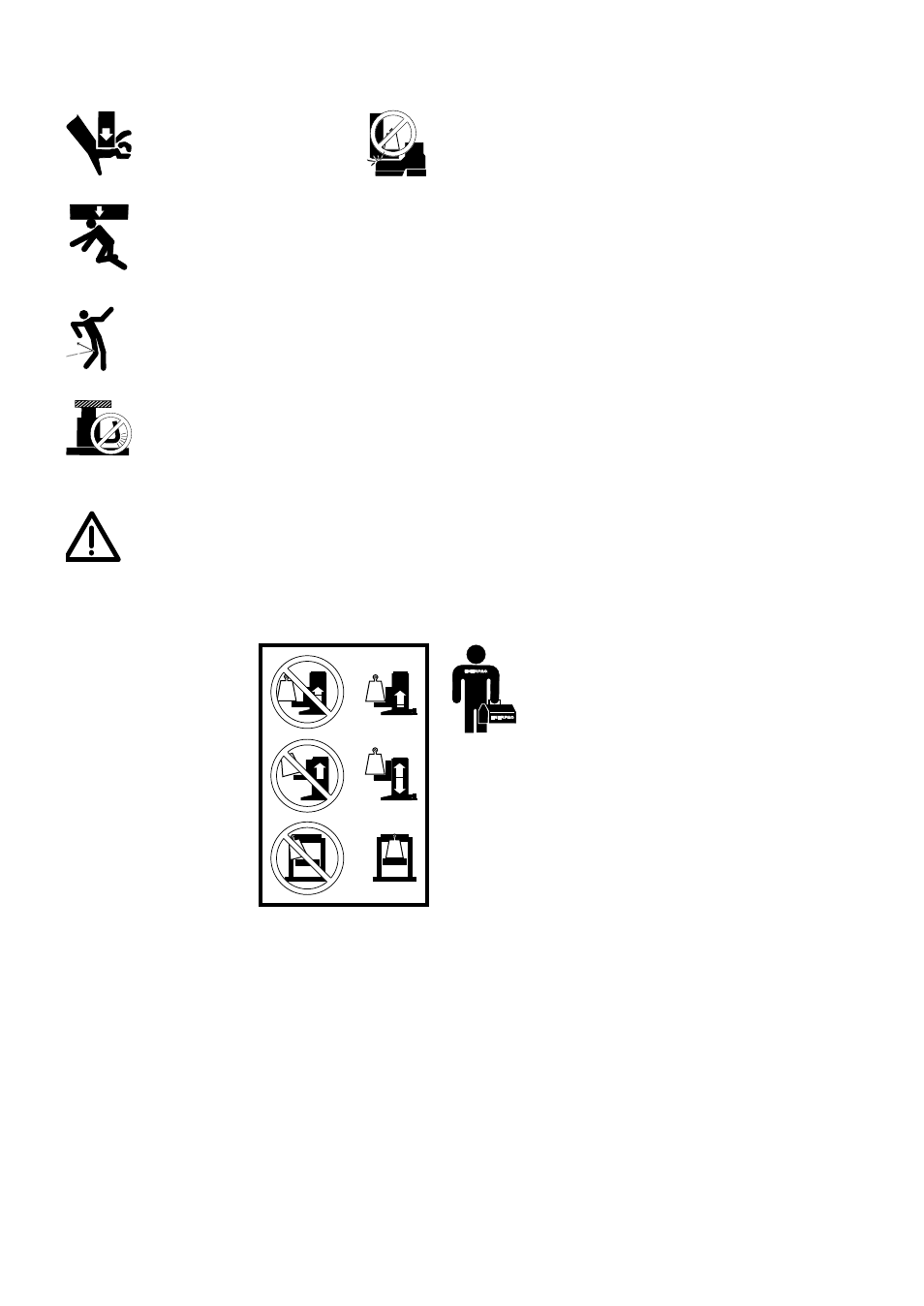

DANGER: To avoid personal

injury keep hands and feet

away from cylinder and

workpiece during operation.

WARNING:

Stay clear of loads

supported by hydraulics. After the load

has been raised or lowered, it must always

be blocked mechanically.

WARNING:

Never pressurize

uncoupled couplers. Only use hydraulic

equipment in a coupled system.

CAUTION: Avoid sharp bends and kinks

in the hose which may cause damage.

Also, bends and kinks lead to premature

hose failure.

4.0 OPERATION

IMPORTANT: It is mandatory that the

operator has a full understanding of all

instructions, safety regulations, cautions

and warnings, before starting to operate

any of this high force tool equipment. In case of

doubt, contact Enerpac.

4.1 Before lifting a load

The cylinder must be

securely attached in the

toe lift base. Keep the

contact surface between

the toe lift and the load

clean. The contact surface

must be free of oil and

grease to avoid the load

slipping off.

Before lifting a load make

sure that the contact

surface of the toe lift

completely support the

load to avoid bending of

the toe.

The chains with the lock pins must always be

positioned in the support feet before lifting to avoid

the support feet from accidentally be moved during

lifting.

4.2 Advancing and retracting the jack

For complete operating instructions refer to the

instruction sheet included with each pump.

Handpumps

On handpumps with release valves, close relief valve

and raise and lower the pump handle to advance the

jack. To retract the jack, open the release valve.

On handpumps with two position valves, shift valve to

advance position and raise and lower the pump

handle to advance. To retract, shift the valve to the

retract position.

IMPORTANT: Open the pump relief valve slowly in

order to lower the load slowly.

Power pumps

Shift the valve on the pump to the advance position

and run the pump to advance the jack. To retract the

jack, shift the valve to the retract position.

4.3 Air removal

Advance and retract the jack several times avoiding

pressure build-up. Air removal is complete when the

jack motion is smooth.

5.0 MAINTENANCE AND SERVICE

Maintenance is required when wear or leakage is

noticed. Periodically inspect all components to detect

any problem requiring service and maintenance.

Enerpac offers ready-to-use spare parts kits for

repair and/or replacements. Contact Enerpac.

IMPORTANT: Hydraulic equipment must

only be serviced by a qualified hydraulic

technician. For repair service, contact the

Authorized Enerpac Service Center in

your area.

• Periodically inspect all components to detect any

problem requiring maintenance and service.

Replace damaged parts immediately.

• Do not exceed oil temperature above 60˚C [140˚F].

• Keep all hydraulic components clean.

• Periodically check the hydraulic system for loose

connections and leaks.

• Change hydraulic oil in your system as

recommended in the pump instruction sheet.

• IMPORTANT: Always keep the guidings of the

lifting plate greased.

6.0 TROUBLESHOOTING

The trouble-shooting table 6.1 on page 3 is intended

to be used as an aid in determining if a problem

exists.

23t