Assembly & installation – Danuser 9000 Postmaster/SlabBlaster User Manual

Page 10

10

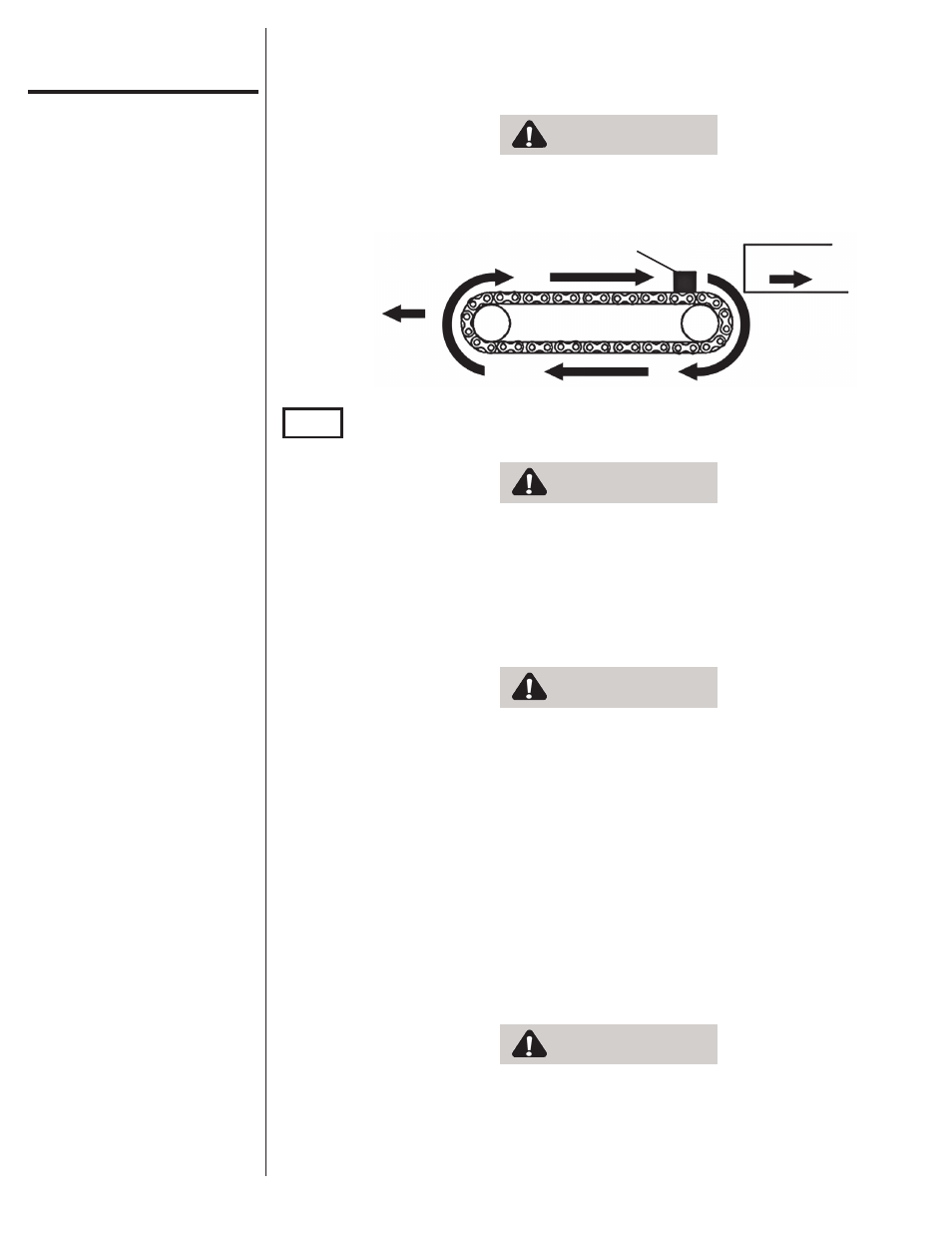

STEP 13: Start the vehicle. Running at full throttle, engage the auxiliary hydraulics. Note

the direction of the chain rotation (visible from the operator’s seat). The chain

should be rotating from the bottom to the top. If it is not, reverse the hydraulic

hoses.

STEP 14: Check the hydraulic system for leaks.

STEP 15: After the correct chain rotation has been achieved, count the number of rotations

of the pick-up link per minute.

STEP 16: The number of rotations equals the number of hammer strikes per minute. If you

want to increase the speed, then increase the flow control setting by 1 increment

at a time until you reach the desired number of rotations per minute. DO NOT

exceed the maximum of 50 rotations per minute.

Keep hands and loose clothing clear of the chain drive

assembly. Severe personal injury could occur.

w A R N I N G

Exceeding 0 rotations per minute will cycle the chain faster

than the hammer drops, making the chain come into contact

with the hammer as it is still falling. This will cause severe

damage to the drive assembly.

w A R N I N G

If the Grapple is installed and the chain is not rotating at all, reverse the

hydraulic hoses.

NOTE

Assembly &

Installation

(continued)

Remember hydraulic systems are under pressure whenever

the engine is running and may hold pressure after

shutdown. Before connecting or disconnecting hydraulic

hoses, be sure to relieve all pressure by cycling all

hydraulic controls after shutdown.

w A R N I N G

Never check pressurized system for leaks with your bare

hand. wear proper hand and eye protection and use wood

or cardboard when searching for suspected leaks. Oil

escaping from pinhole leaks under pressure can penetrate

skin and create a serious medical emergency. If any fluid

is injected into the skin, gangrene, blood poisoning, even

death may result. Obtain medical attention immediately.

w A R N I N G

Pick-Up Link

Hammer

Vehicle