8 trailer service, 9 greasable bearings (670cc model), 10 unplugging the rotor – Echo DL10570 Owners Manual v.1 User Manual

Page 23: Warning

Debris Loader Owner’s Manual

19

SERVICE AND MAINTENANCE

Greasable bearings can be found on 670cc Honda engine

models. Mounted bearings are pre-lubricated at our factory

and are ready for operation.

RELUBRICATION:

Relubrication of bearings is determined by operating condi-

tions and environment. Lubricate standard bearings with a

LITHIUM based grease. Greasing intervals and quantities

are shown on Figure 21 using the following symbol:

GREASING INTERVALS:

Bearings in extreme environments will require more fre-

quent greasing intervals.

GREASE FILL AMOUNTS:

It is preferred that experience dictate fill amounts due to

wide variances in applications, greasing equipment and

operating conditions. The quantity shown is the recom-

mended amount. In most cases, it is best to lubricate in

small amounts, under low pressure, until a thin bead of

fresh grease is visible at the seal lip area.

Care should be taken when greasing bearings to avoid

overfilling. Overfilling can lead to excessive heat and/or un-

seating of the seals. Grease should be introduced in small

amounts and under light pressure. Whenever possible, the

bearing should be rotated slowly while grease is added to

ensure equal distribution throughout the raceways.

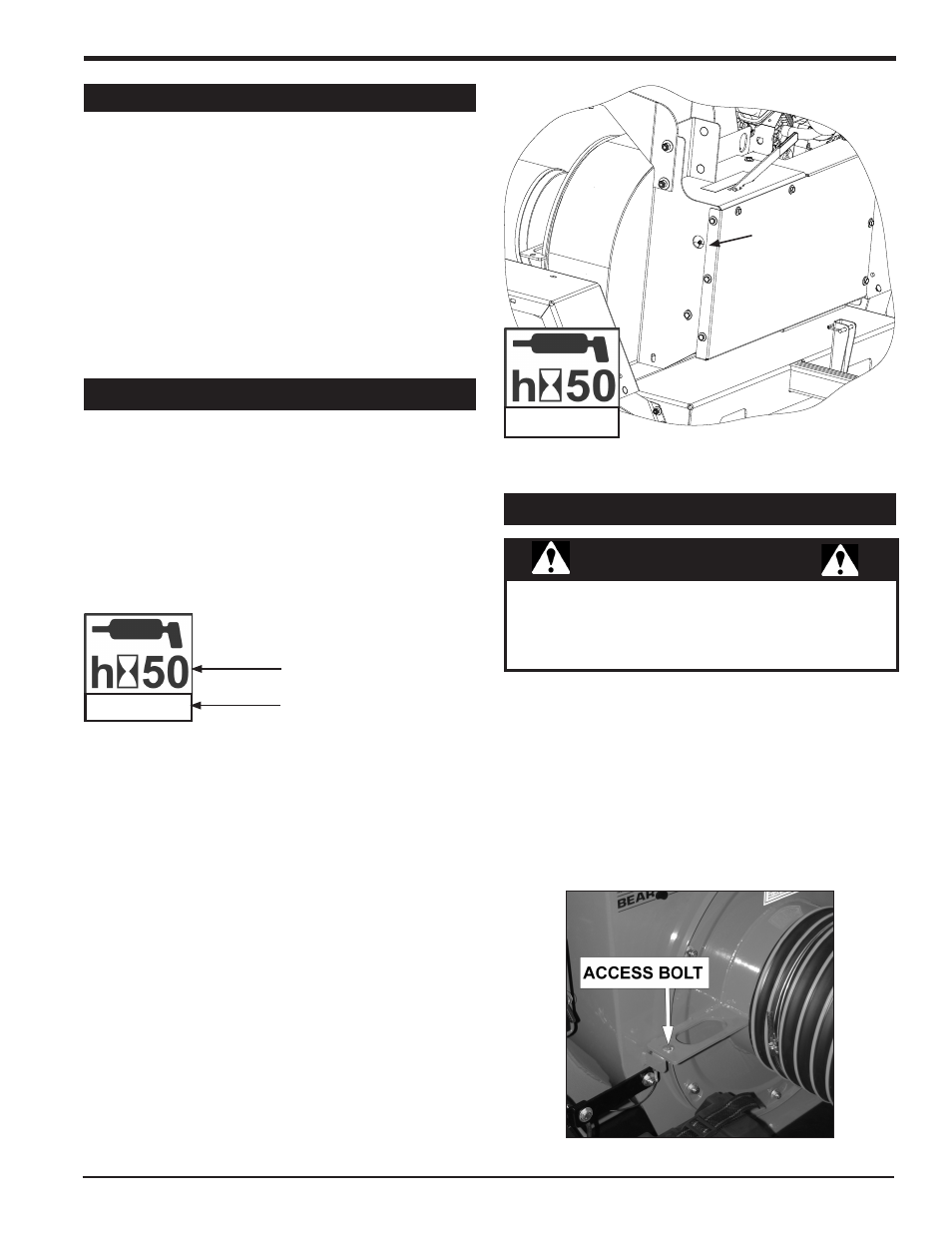

Quantity

Frequency (50 hours)

Recommended

Qty. of grease.

Figure 21, Grease zerk, DL12670 (75124)

Grease Zerk

.18 OZ

5 GRAMS

5.9 GREASABLE BEARINGS (670cc MODEL)

The debris loader is designed to be used in fairly dry

conditions. Wet material, along with too much debris and

large sticks, can plug the rotor or hose. A plugged rotor

bogs down the engine and can possibly stop the engine if

the rotor is severely plugged. To clear the rotor:

5.10.1 12 INCH MODELS

1. Shut off engine and allow rotor to completely stop.

2. Remove spark plug wire.

3. Remove the access bolt (Figure 22).

Figure 22, Access bolt

1. Check wheel lug nut torque after the first 8 hours of tow-

ing. Check monthly thereafter.

2. Check air pressure in tires after the first 8 hours of towing.

Check monthly thereafter. Fill tires to 60 PSI.

3. Check and repack wheel bearings with grease every

year.

4. Always connect the safety chains when towing. Ensure

trailer hitch bolts are tight and secure.

5. Check trailer lights.

5.8 TRAILER SERVICE

Before inspecting or servicing any part of this machine,

shut off power source, disconnect spark plug wire from

spark plug and make sure all moving parts have come

to a complete stop.

WARNING

5.10 UNPLUGGING THE ROTOR