Warning – Echo 74500 Owners Manual v.4 User Manual

Page 19

5" and 8" Skid Steer Chipper Owner's Manual

17

SERVICE & MAINTENANCE

BeFOre iNSPeCtiNg Or ServiCiNg aNy Part OF tHiS MaCHiNe, SHut OFF POWer SOurCe,

diSeNgage tHe HydrauliCS aNd Make Sure all MOviNg PartS Have COMe tO a COMPlete StOP.

Warning

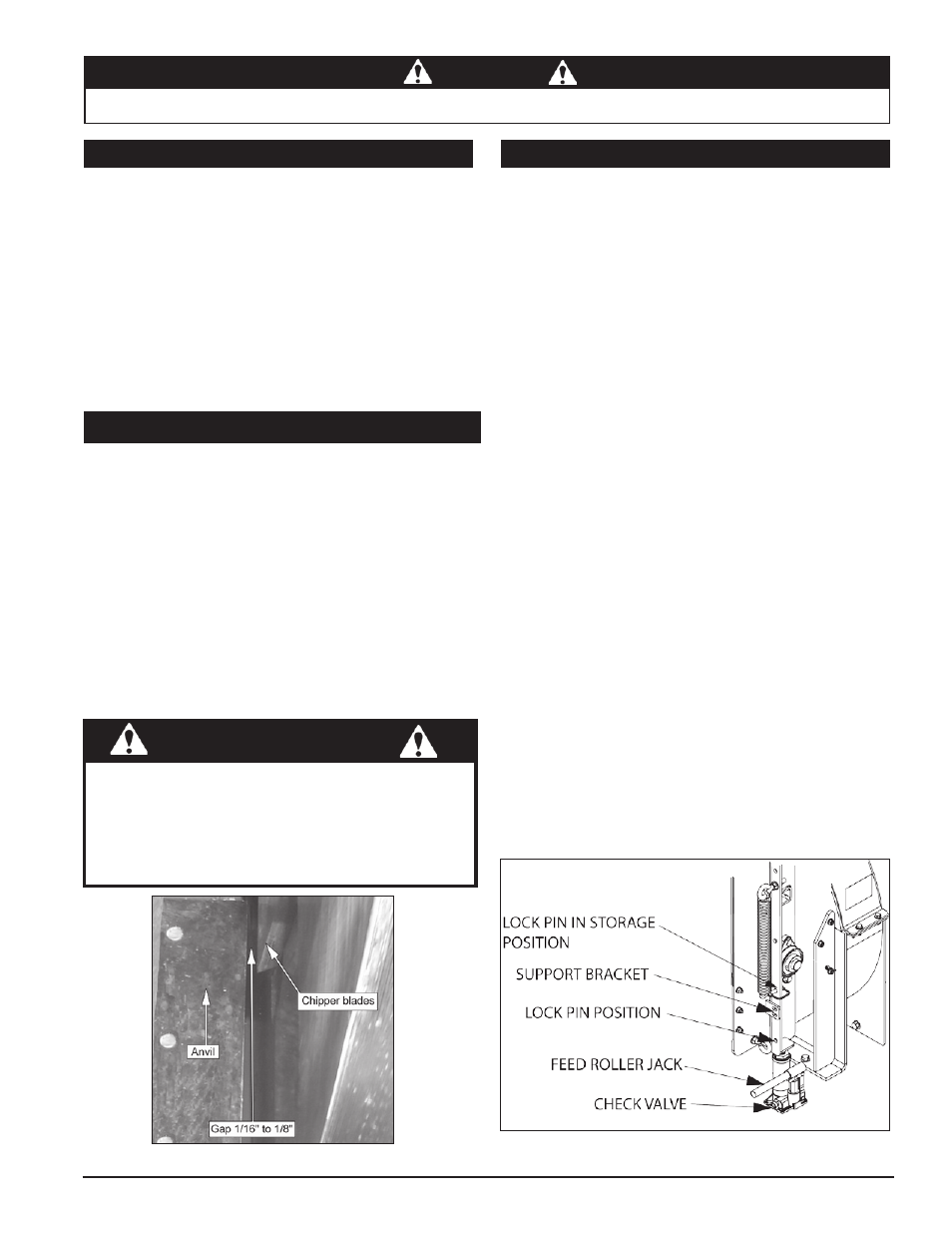

the chipping blades should clear the anvil by 1/16 to 1/8

inch. To adjust the blade clearance, proceed as follows:

Adjust the anvil by loosening the two (74500) or three

(74800) anvil bolts.

On the 74500, move the anvil assembly in or out by

turning the nuts on the block adjuster weldment.

On the 74800, with the three anvil bolts loosened,

adjust the anvil to the desired position.

if the anvil cannot be moved to specifications due to

wear, rotate the anvil or replace the anvil.

Secure all hardware and adjust to torque.

1.

2.

3.

4.

5.

Figure 5.3 - Anvil and Chipper Blade Clearance

remove any accumulated material from the blade

pocket and the bottom of the chipper blade.

reinstall the chipper blades and tighten the bolts to a

torque of 25 Ft-lbs. (74500) or 120 Ft-lbs. (74800).

Check the blade/anvil clearance and adjust if necessary.

Close the chipper housing and secure with removed

bolts to a torque of 25-28 Ft-lbs.

reconnect machine hydraulics.

1.

2.

3.

4.

5.

it is important to ensure that the minimum gap between

the chipping anvil and all chipping blades is 1/16". all

chipping blades should be rotated until even with the

chipping anvil and then measured. Failure to do so

can result in the chipping blades striking the chipping

anvil causing serious injury or death.

Warning

5.5 insTalling The blades

5.6 seTTing blade clearance

5.7 clearing a Plugged roTor

The feed roller lift jack is used to raise the feed roller if

chipping material becomes wedged in or behind the feed

roller. raise the feed roller and the chipper housing to

safely remove the material.

Stop skid steer engine, disengage hydraulics, and

allow machine to come to a complete stop.

Position the chipper chute to the side of the chipper.

remove the two bolts on the chipper blade access

cover.

tip the cover away from the chipper to expose the

rotor and the blades.

Turn the check valve located on the bottom of the jack

clockwise, engaging the jack.

remove the lock pin from its storage posistion (see

figure below).

Pump the handle to raise the feed roller until the lock

pin position aligns with one of the support bracket

holes.

Secure the position by putting the lock pin through the

support bracket and lock pin position. this will ensure

the feed roller cannot fall from the upright position.

Clear the unit of debris.

to lower the feed roller support, remove the lock

pin and then turn check valve counterclockwise to

disengage the pump.

replace lock pin in storage position.

leaving

The lock Pin in anY oTher PosiTion maY

inTerfere WiTh feed roller oPeraTion.

lower access cover and reattach the two bolts.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Figure 5.4 - Feed Roller Lock