3 replacing chipping blades – Echo 77412 Owners Manual v.1 User Manual

Page 19

Page 17

4.5" BearCat Chipper Operator's Manual

SERVICE AND MAINTENANCE

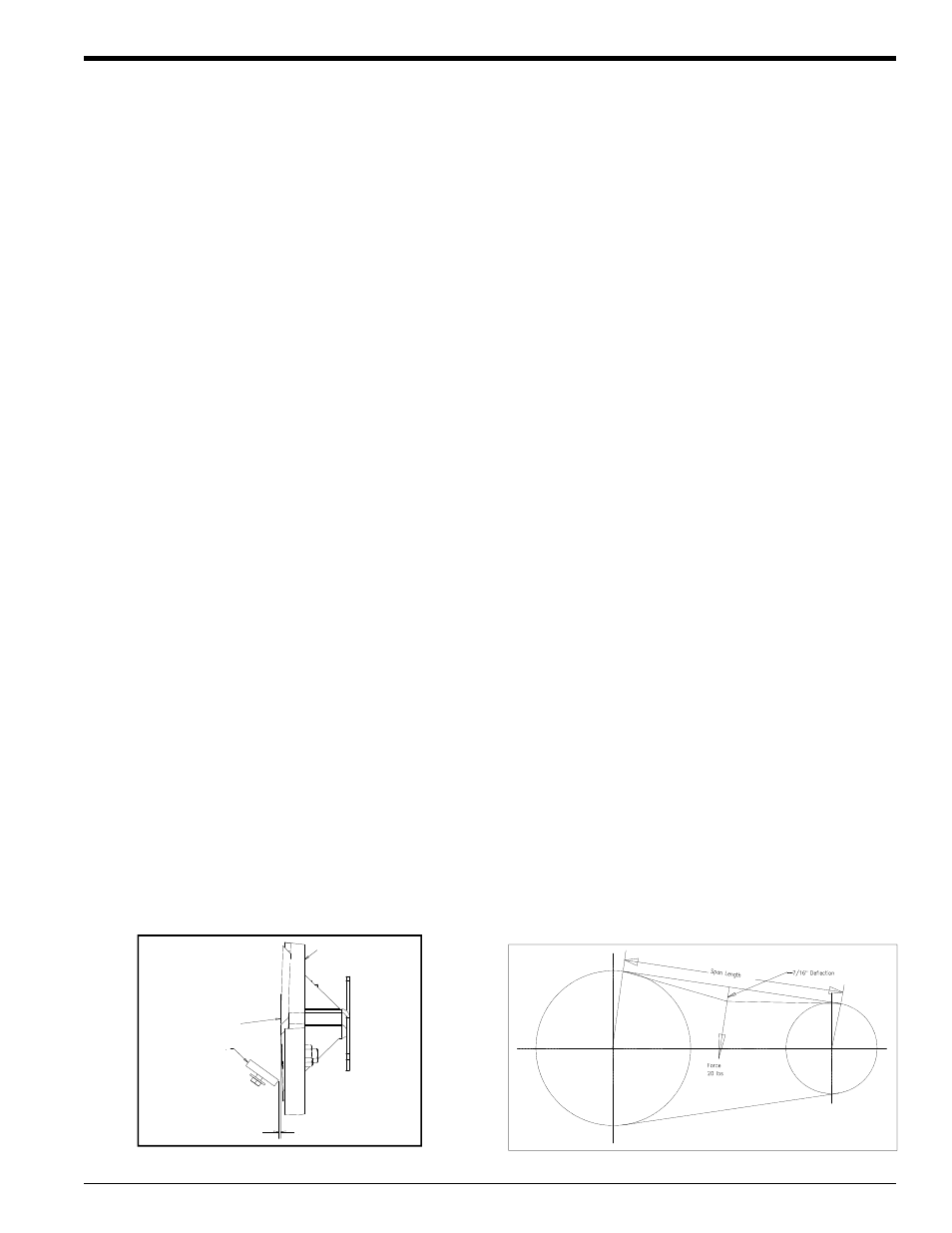

The chipping blades should clear the chipping anvil located

directly under the chipper chute by 1/16 inch. To adjust the

blade clearance, proceed as follows:

1.

Removing the chipper chute is NOT required for setting

the chipping blade clearance, although, removing the

chipper chute can provide better access for measuring

the chipping blade clearance.

2.

Rotate the disk until a chipping blade is even with the

chipping anvil.

3.

Measure the amount of clearance between the chip-

ping blade and chipper anvil from inside of the chipper

housing. The gap should be 1/16 inch (Figure 5.3).

4.

Adjust the anvil by loosening the 5/16" x 5/8" bolts

holding the anvil to the disk cover and sliding the anvil

inward or outward until the desired measurement is

achieved.

5.

Tighten the bolts and torque to 75 Ft-lbs.

6.

IMPORTANT: Repeat for the remaining chipping blades.

7.

Reinstall the chipper chute.

If the chipping anvil edge is damaged or worn unevenly,

remove the three bolts and washers holding the anvil to the

disk cover and use one of the other three edges. Adjust for

correct measurement.

5.3 REPLACING CHIPPING BLADES

If the chipper blade does not extend beyond the disk chip-

ping slot, follow the steps below to replace the chipping

blade:

1.

Remove the chipper deflector or discharge tube.

2.

Lock rotor assembly (Section 5.1).

3.

Remove the two 1/2" x 1-3/4" flat head screws holding

the blade to the disk.

4.

Remove the old blade, install the new blade and torque

to 75 Ft-lb. Repeat this procedure for each blade.

5.4 SETTING CHIPPING BLADE

CLEARANCE

5.5 ADJUSTING THE DRIVE BELT

Check the condition of the drive belt annually or after every

25 hours of operation, whichever comes first. Replace a

cracked, frayed, worn or stretched drive belt. Only replace

drive belt with original banded type belt. Do not use single

type belts. To adjust the drive belt, proceed as follows:

1.

Move the chipper engagement lever to the start posi-

tion.

2.

Shut engine off.

3.

Disconnect battery cables.

4.

Remove the belt shield by removing the seven 5/16" x

3/4" bolts securing the belt shield to the shield weldment.

5.

Loosen the 5/16" bolt attaching the belt guide to the

engine.

6.

To increase tension on the belt, do the following:

6a. Loosen the four carriage bolts attaching the

engine plate to the trailer.

6b. Locate the two 5/16" x 2" bolts and 5/16" flange

nuts located on the side of the chipper between

the trailer and the engine plate.

6c. Loosen both 5/16" flange nuts.

6d. Tighten both 5/16" bolts equally to move the

engine away from the chipper housing until the

belt deflection is 7/16" when a 20 lb. load is

placed against the belt (Figure 5.4).

6e. Tighten the four carriage bolts securing the en-

gine plate to the trailer.

6f. Once the proper deflection is achieved, tighten

both 5/16" flange nuts to ensure the proper de-

flection is maintained.

7.

If the bolts and nuts between the engine plate and the

trailer cannot be adjusted any further and the tension

needs further adjustment, tighten the eyebolt until the

appropriate deflection is achieved.

8.

Replace the belt if no adjustment is left (Section 5.6).

9.

Replace belt shield.

Figure 5.4 - Belt Tension

Figure 5.3 - Chipper Blade and Anvil Clearance

Chipper Disk

Chipper

Blade

Anvil

1/16"