9 lubrication, 10 pto lubrication, 9 lubrication 5.10 pto lubrication – Echo 73413 Owners Manual v.3 User Manual

Page 22: Important, Warning

4 INCH CHIPPER

18

SERVICE & MAINTENANCE

WARNING

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE AND MAKE SURE

ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

5.9 LubRICaTIoN

5.10 pTo LubRICaTIoN

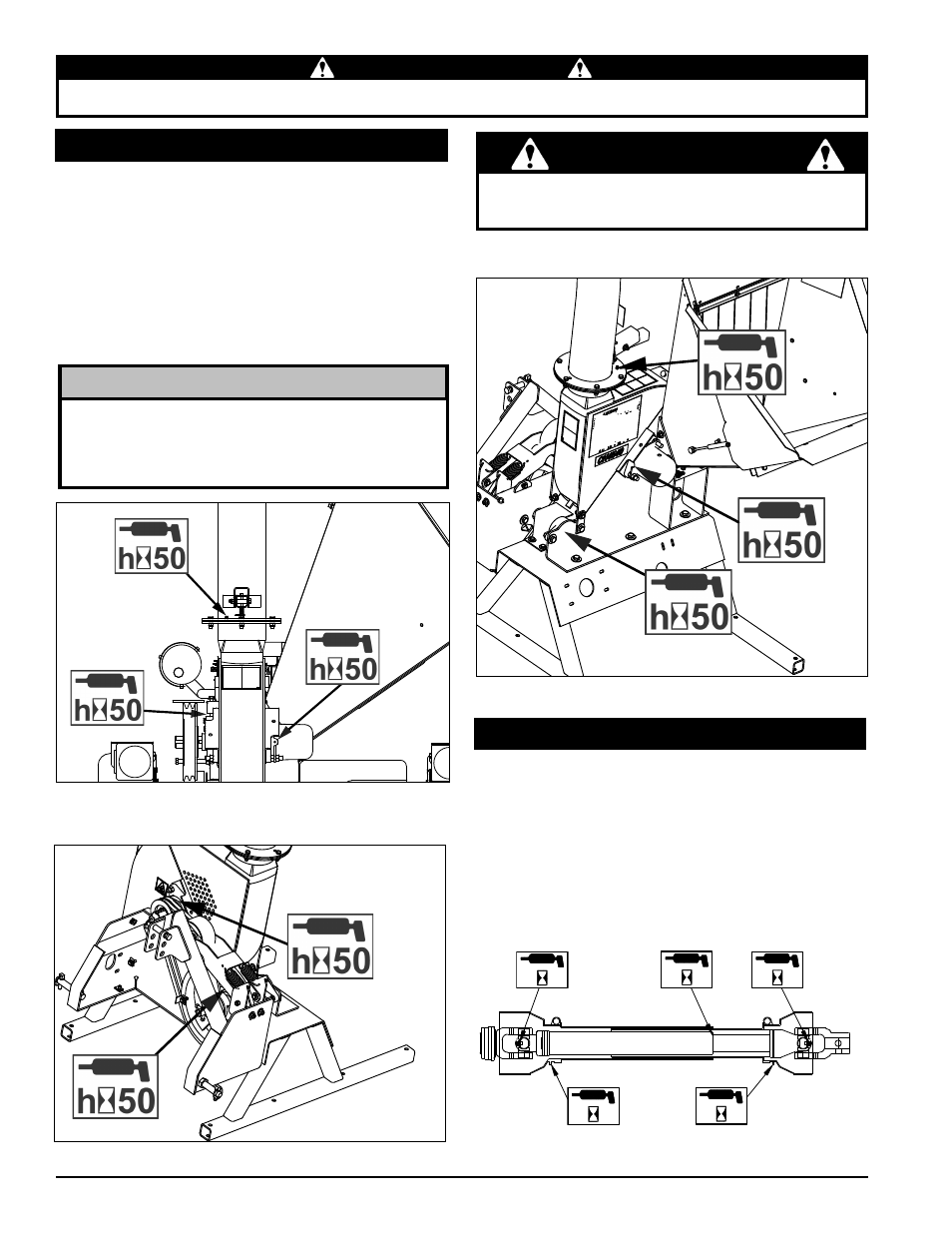

Figure 5.11. PTO lubrication

Fig. 5.8. Grease zerks on CH4614 (73420)

Fig. 5.9. Grease zerks on CH4540 (73454)

Fig. 5.10. Grease zerks on CH4540 (73454)

• Two bearings on the rotor shaft.

• One grease zerk on the discharge chute.

• One grease zerk behind pulley (engine model).

• One grease zerk underneath bearing (engine

model).

lubricate the machine periodically with a lithium-based

grease. Extreme working conditions will require more

frequent greasing.

grease the following points every 50 hours of operating

time:

Underneath

bearing

8

h

8

h

8

h

8

h

8

h

ImpoRTaNT

Polyurea and lithium-based greases are not compatible.

Mixing the two grease types may lead to premature failure.

Do not over grease bearings. Overfilling can lead to

excessive heat and/or unseating of the seals. Add

grease slowly and under light pressure. Whenever

possible, rotate bearing slowly while lubricating.

NoTE

1. Every 8 hours, lubricate PTO cross journals. Make sure

grease purges through all four bearings.

2. Every 8 hours, lubricate PTO inner tubes. Telescoping

members must have lubrication to operate successfully.

Telescoping members without fittings should be pulled apart

and grease should be added manually with a brush.

3. Every 8 hours, lubricate the PTO shield retaining bearing.

Molded nipples on the guard near each guard bearing are

intended as grease fittings and should be lubricated every

8 hours of operation.