10 connect pto driveline, Important, English – Echo CH4540 Owners Manual v.2 User Manual

Page 13

4 INCH CHIPPER

9

ENGLISH

ASSEMBLY

2.10.1 CHECk LENGTH oF pTo dRIvELINE

attach chipper to tractor with three-point hitch.

1.

You must make sure that the pto driveline supplied

2.

with your machine is the appropriate length for your

tractor. Adjust the chipper up and down and measure

the shortest and longest distance between the chipper

rotor shaft and tractor PTO.

the pto driveline has a

3.

maximum extension of

24.49" with a 6.43" overlap. If your longest distance

is greater than 24.49", contact your dealer to obtain

a longer pto driveline.

the pto driveline has a

4.

minimum compression of

18.1". If your shortest distance is less than this, cut the

driveline to fit as explained in section 2.10.2.

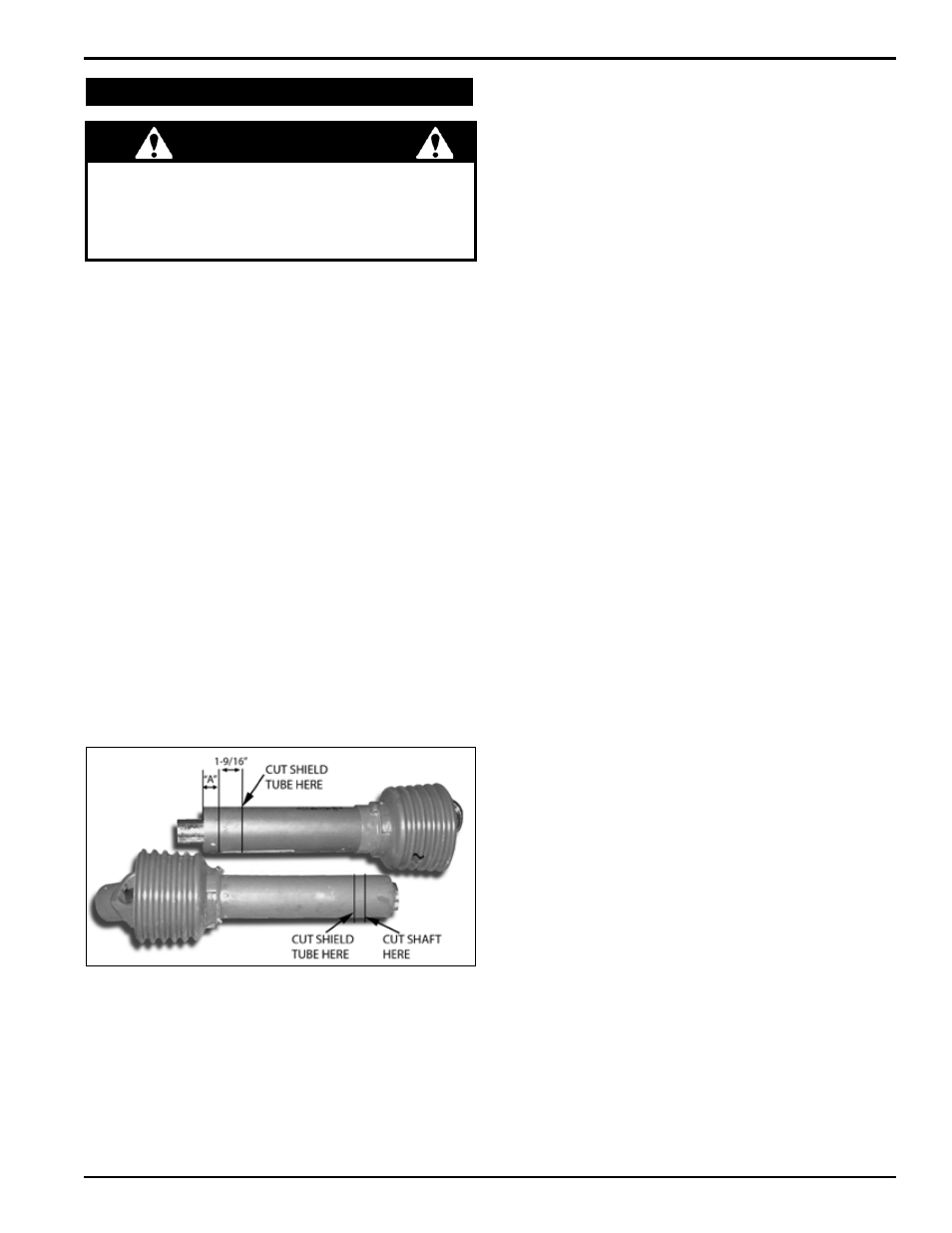

2.10.2 SHoRTENING a pTo dRIvELINE

pull the driveline into two pieces. Connect one end to

1.

the tractor pto and the other end to the chipper rotor

shaft. line up the two halves parallel to each other.

Measure the distance from the end of one driveline tube

2.

to the bottom of the end shield of the other driveline

half (dimension A in Fig. 2.6). Measure and mark the

driveline tube 1-9/16” inward from dimension A.

Cut the shield tube in the marked position.

3.

using the cut piece of shield tube as your measurement,

4.

place the cut piece against the end of the shaft. Mark

and cut the shaft.

using the cut piece of shield tube as your measurement,

5.

mark and cut the tube on the other half of the driveline,

and then the shaft.

2.10 CoNNECT pTo dRIvELINE

Figure 2.6 Shorten the driveline if it is too long

ImpoRTaNT

File both shaft ends, and slide the two halves back

6.

together.

2.10.3 CoNNECTING THE pTo dRIvELINE

When you have confirmed that the driveline is the

1.

correct length for your tractor, connect the driveline

to the chipper rotor shaft using key stock and two set

screws in the owner’s kit.

Connect the opposite end of the PTO shaft to the

2.

tractor.

the tractor must have a

•

standard 540 Rpm pTo

shaft.

If the tractor has an electric PTO clutch, consult

•

your dealer for correct operating procedures.