8 clearing a plugged rotor, 9 filling hydraulic fluid, English – Echo CH611DH Owners Manual v.5 User Manual

Page 25

21

6 INCH CHIPPER

ENGLISH

SERVICE & MAINTENANCE

Before inspecting or servicing any part of this machine, shut off power source,

disengage the hydraulics, and make sure all moving parts have come to a complete stop.

WARNING

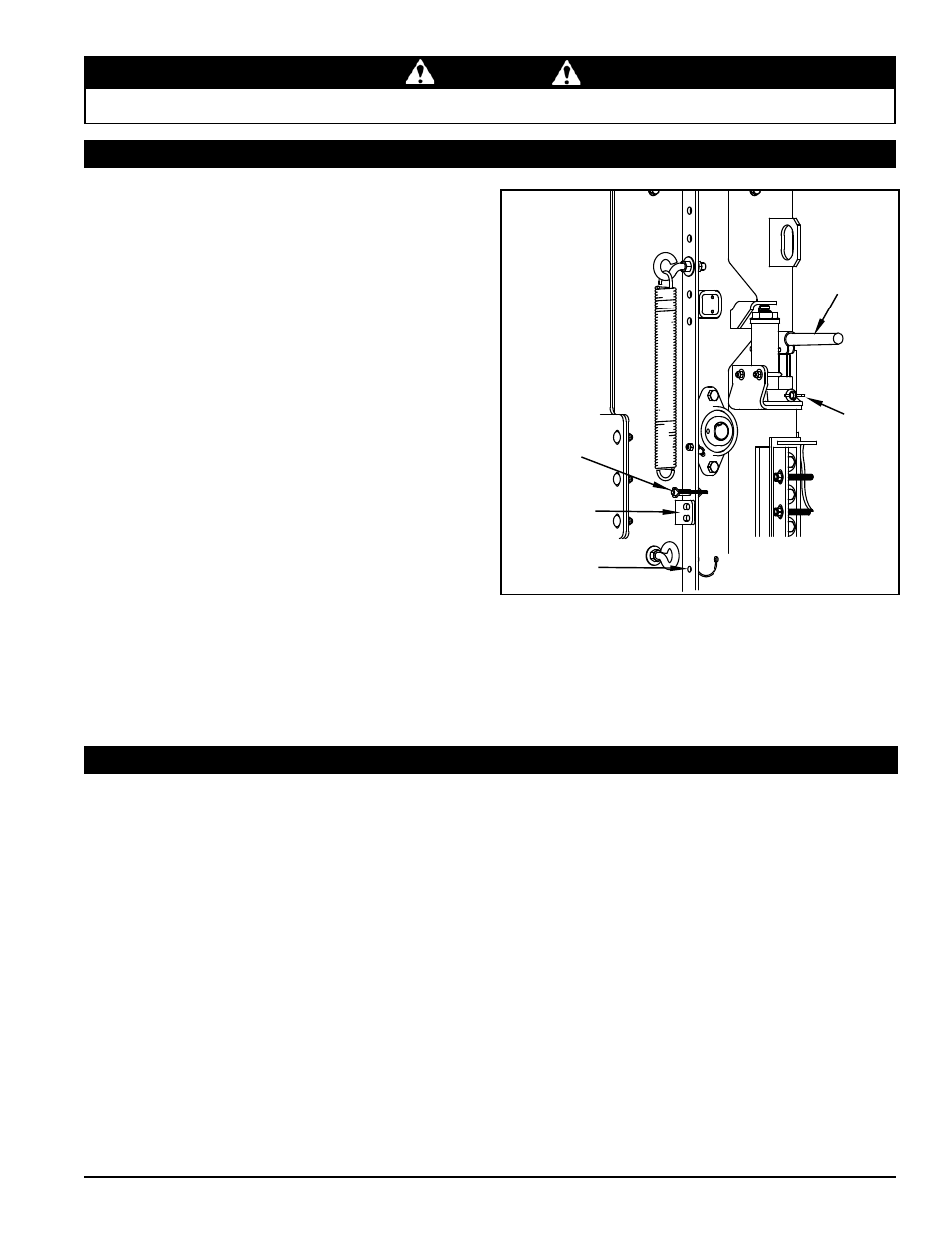

5.8 clearinG a pluGGeD roTor

FEED

ROLLER

JACK

LOCK PIN

STORAGE

POSITION

SUPPORT

BRACKET

LOCK PIN

POSITION

CHECK

VALVE

Feeding too large or too much material at once may plug

the chipper. To clear a plugged disk, proceed as follows:

1. lift the engagement handle and turn off engine key

switch. Allow all moving parts to come to a complete

stop.

2. Remove the two 3/8” retaining bolts holding the access

cover to the chipper frame and lift up access cover.

3. Remove the lock pin from storage position (see

below).

4. Turn check valve clockwise to engage the jack pump.

5. Pump the handle to raise the feed roller until the lock pin

position aligns with one of the support bracket holes.

6. Secure the position by putting the lock pin through the

support bracket and lock pin position.

7. Clean the debris away from the chipper disk. Turn the

disk by hand to be sure it is free to rotate. Be careful

to avoid the chipper blades when cleaning out the

debris.

8. Remove the lock pin and put it back in storage

position. lEAVINg THE lOCK PIN IN ANy OTHER

POSITION MAy INTERFERE WITH FEED ROllER

OPERATION.

9. Turn the check valve counterclockwise to disengage the pump and lower the jack.

10. Close access cover and replace bolts.

11. Start the engine. lower the engagement handle when engine is running to engage drive belt. Resume operation at

1/4 throttle.

5.9 FillinG hYDraulic FluiD

Hydraulic fluid drives the feed roller. Check the fluid

level daily and fill as needed. The fluid and filter should

be changed and system cleaned if the fluid becomes

contaminated with foreign matter (water, dirt, grease, etc.)

or if the fluid has been subjected to temperatures greater

than the maximum recommended.

The hydraulic pump requires premium hydraulic fluids

containing high quality rust, oxidation, and foam inhibitors.

These include premium turbine oils, API CD engine oils

per SAE J183, M2C33F or g automatic transmission

fluids meeting Allison C-3 or Caterpillar TO-2, and certain

specialty agricultural tractor fluids.

In the unlikely event that the oil is completely drained

from the hydraulic system, oil must be added and any air

bubbles must be purged from the system. To do this:

1. Clean all system components (reservoir, fittings,

etc.).

2. Fill the hydraulic reservoir.

3. Start the engine and run at the lowest possible RPM.

4. As you purge air from the unit, the oil level in the

reservoir will drop and bubbles may appear in the fluid.

Refill the reservoir as necessary.

5. Run the feed roller in both directions for several minutes

until any remaining air purges from the unit. Refill the

reservoir as necessary.

6. Shut down the engine, check for and correct any

fluid leaks, and check the reservoir level. Add fluid

if necessary. The hydraulic pump is now ready for

operation.