4 sharpening the blades, 3 removing the blades, 2 chipper blade maintenance – Echo 72620 User Manual

Page 17: Warning, Warning 5.2 chipper blade maintenance

6 INCH CHIPPER

13

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE,

ANd MAKe suRe All MoVINg PARts hAVe CoMe to A CoMPlete stoP.

Warning

5.2 chiPPer blade mainTenance

Warning

When working on the rotor assembly, use the lock

mechanism at all times. Remove plastic bearing cover

under the chipper chute. there is a hole in the rotor

jack shaft and a matching hole in the bracket mounted

to the rotor bearing front side. Install a punch through

the rotor shaft and bracket to lock the rotor in place.

1. Remove the two retaining bolts holding access cover

to main frame assembly.

2. tilt access cover over to allow rotor access. Rotate

the rotor so that the bolts holding a chipping blade are

most accessible.

3. Remove the two nuts holding the blade itself. Repeat

for all four blades. The four chipping blades have two

edges per blade and can be reversed one time each

before sharpening. If both sides have not been used,

remove and reverse the chipping blades. Reinstall

chipping blades and proceed with chipping.

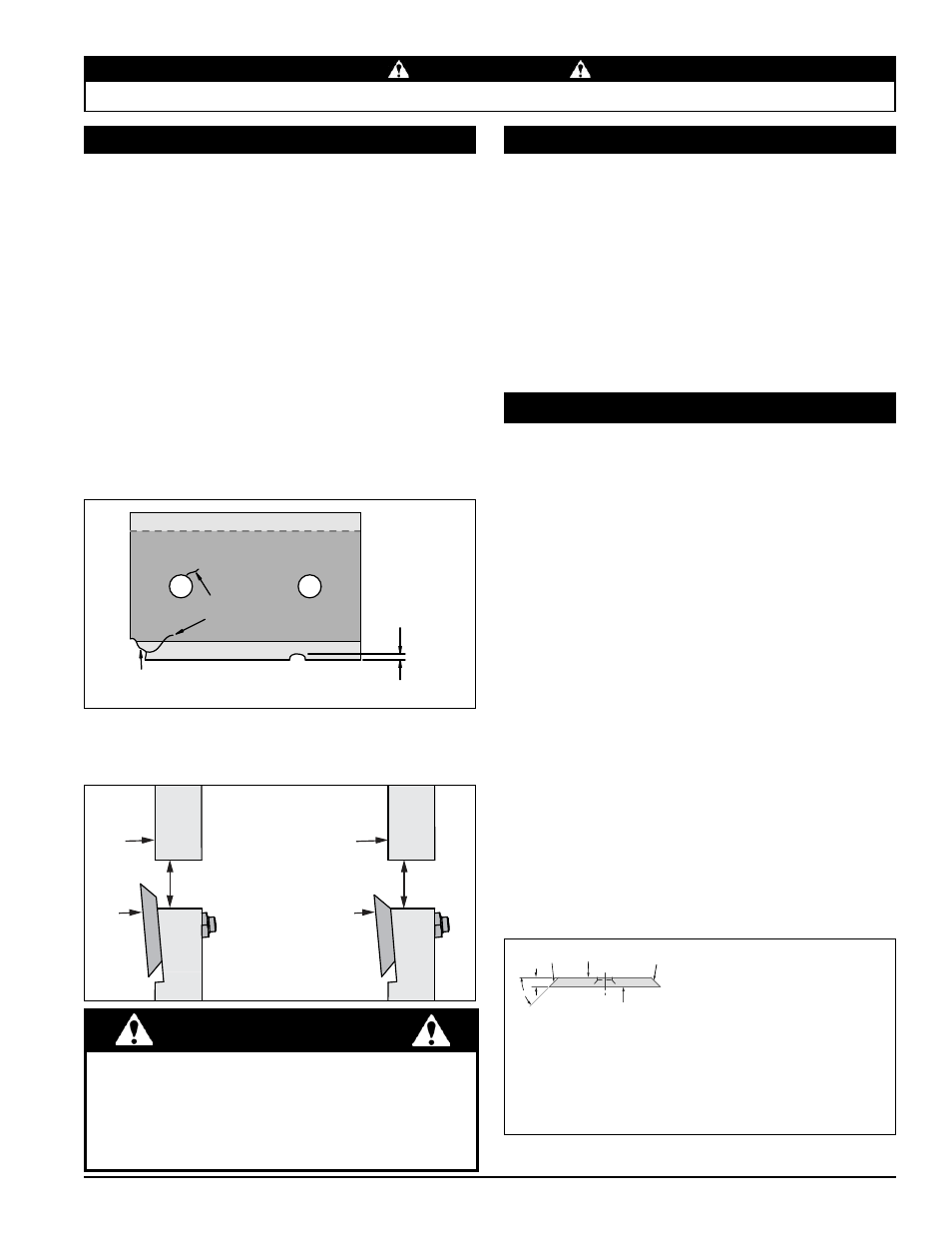

Figure 5.1, Sharpening the chipper blades

45˚

SHARPENED

SURFACE

MOUNTING SURFACE

(DO NOT GRIND)

.38

SHARPENED

SURFACE

MOUNTING SURFACE

(DO NOT GRIND)

The chipper blades will eventually become dull, making

chipping difficult and adding extra strain on the machine.

checK The sharPness of The blades everY

5 - 15 hours of oPeraTion and sharPen as

needed.

Your blades need to be sharpened if:

•

Machine vibrates severely when material is fed into the

chipper.

•

Small diameter branches do not self-feed.

•

Chips discharge unevenly or have stringy tails,

especially when chipping green branches.

Before you sharpen the chipping blades, check for

permanent damage. Replace the blade if:

•

there are cracks, broken corners or nicks greater than

1/8" (see below).

5.3 removing The blades

NICK GREATER

THAN 1/8”

CRACK

GREATER

THAN 1/8”

BROKEN

CORNER

• The base of the cutting edge is worn or has been re-

sharpened so that it no longer extends past the chipping

slot (see below).

NEW

BLADE

CHIPPER

DISC

CHIPPING

SLOT

CHIPPER

DISC

BLADE IS

TOO SHORT,

MUST BE

REPLACED

CHIPPING

SLOT

The blades can be ground on a bench grinder or by a

professional.

Never sharpen or grind the mounting surfaces of the

1.

blades. this will cause the edge to roll and the blade will

be damaged, resulting in poor chipping performance.

Regrind the angled edge of the chipping blades to 45

2.

degrees (Figure 5.1). Make sure some type of fixture is

used to correctly hold the blade at the proper angle.

Be careful when grinding so that the blade does not

3.

become overheated and change color. this will remove

the heat-treated properties.

use short grinding times and cool with water or some

4.

type of liquid coolant.

Remove an equal amount off each blade to maintain

5.

rotor balance.

Small imperfections such as nicks and burrs on

6.

the flat side of the blade will not affect the chipping

performance of the machine.

For blades that have been repeatedly sharpened,

7.

ensure that the sharpened surface extends past the

chipping slot opening. If it does not extend past the

opening, the blades should be replaced.

5.4 sharPening The blades