4 function speeds, Machine orientation when doing speed tests, Test notes – JLG 600A_AJ Service Manual User Manual

Page 20: 5 torque requirements, Function speeds -4, Torque requirements -4, Function speeds (in seconds) -4

SECTION 1 - SPECIFICATIONS

1-4

– JLG Lift –

3121201

1.4 FUNCTION SPEEDS

Machine Orientation When Doing Speed

Tests

Lift: Boom Retracted. Telescope Retracted. Lift Up,

Record Time, Lift Down, Record Time.

Swing: Boom at Full Elevation. Telescope Retracted.

Swing the Turntable off center and stop. Swing the oppo-

site direction and start the test when the turntable is cen-

tered up. This eliminates ramp up and down on the

controller affecting times.

Telescope: Boom at Full Elevation; Telescope Retracted;

Telescope Out, Record Time. Telescope In, Record Time.

Drive: Test to be done on a smooth level surface. Drive

Select Switch should be set to High Speed. Start approxi-

mately 25 ft. (7.62 m) from the starting point so that the

unit is at maximum speed when starting the test. Results

should be recorded for a 200 ft. (60.96 m) course. Drive

Forward, Record Time. Drive Reverse, Record Time.

Drive (Above Horizontal): Test should be done on a

smooth level surface. Drive Select Switch should be set to

Low Engine. The boom should be raised above horizon-

tal. Results should be recorded for a 50 ft. (15.24 m)

course. Drive Forward, Record Time. Drive Reverse,

Record Time.

Platform Rotate: Platform level and completely rotated

one direction. Rotate the opposite direction, Record Time.

Rotate the other direction, Record Time.

Articulating Jib: Platform level and centered with the

boom. Start with the Jib down. Jib Up, Record Time. Jib

Down, Record Time.

Lower Lift: Upper boom horizontal, telescoped in, Lower

Lift up, Record Time. Lower Lift Down, Record Time.

Lower Telescope: Lower Lift fully elevated, Upper Boom

horizontal, telescoped in. Lower Tele Out, Record Time.

Lower Tele In, Record Time.

Test Notes

1. Stop watch should be started with the function, not

with the controller or switch.

2. All speed tests are run from the platform. These

speeds do not reflect the ground control operation.

3. The platform speed knob control must be at full

speed (turned clockwise completely).

4. Function speeds may vary due to cold, thick hydrau-

lic oil. Test should be run with the oil temperature

above 100° F (38° C).

1.5 TORQUE REQUIREMENTS

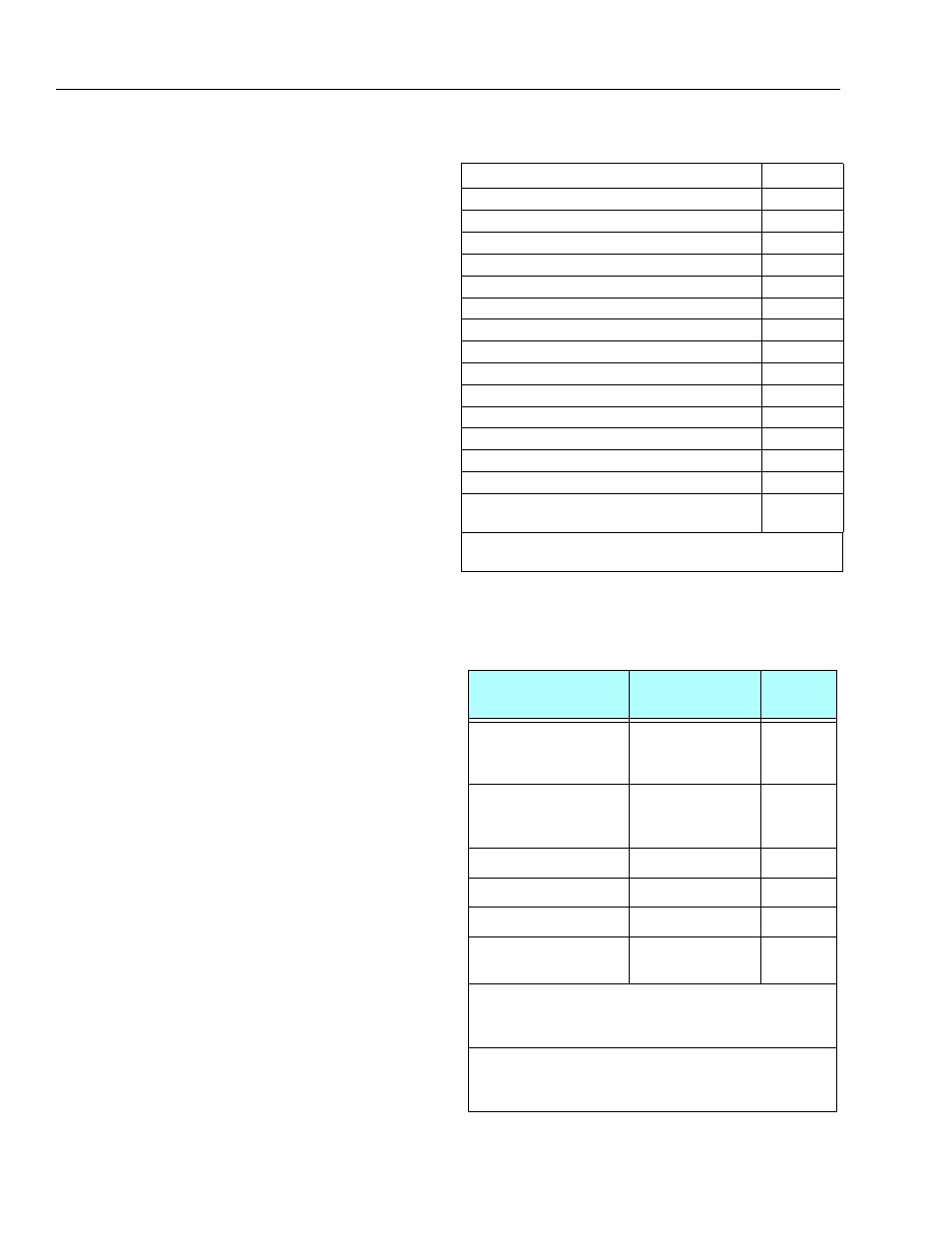

Table 1-14. Function Speeds (In Seconds)

Function

Speed

Lift Up

26-32

Lift Down

26-32

Swing Right & Left*

79-101

Telescope Out

35-50

Telescope In

22-30

Platform Rotate Right & Left**

16-25

Jib Up

22-34

Jib Down

16-26

Lower Lift Up

37-50

Lower Lift Down

28-38

Lower Telescope Out

15-23

Lower Telescope In

09-15

Drive Forward & Reverse (2WD & 4WD) Deutz Engines

33-37

Drive Forward & Reverse (2WD & 4WD) Other Engines

30-34

Drive Above Horizontal Forward & Reverse (2WD &

4WD)

46-54

*Max 10% Difference Between Left & Right

**Max 15% Difference Between Left & Right

4150501 - D

Table 1-15. Torque Requirements

Description

Torque Value (Dry)

Interval

Hours

Bearing To Chassis

190 ft. lbs.

(260 Nm)

See Note

50/600*

Bearing To Turntable

190 ft. lbs.

(260 Nm)

See Note

50/600*

Wire Rope

15 ft. lbs (20 Nm)

150

Wheel Lugs

170 ft. lbs. (231 Nm)

150

Engine Mounting Bolts

165 ft. lbs. (231 Nm)

A/R

Engine Manifold Mounting

Bolts

30 ft. lbs. (42 Nm)

A/R

*Check swing bearing bolts for security after first 50 hours of opera-

tion and every 600 hours thereafter. (See Swing Bearing in Section

3.)

NOTE: When maintenance becomes necessary or a

fastener has loosened, refer to the Torque Chart

to determine proper torque value.