Section 2 - pre-operation and inspection, 1 pre-operation check and inspection, Pre-operation check and inspection -1 – JLG 4017RS Operator Manual User Manual

Page 25: Warning

Section 2 - Pre-Operation and Inspection

2-1

31200938

SECTION 2 - PRE-OPERATION AND INSPECTION

2.1

PRE-OPERATION CHECK AND INSPECTION

Note: Complete all required maintenance before operating unit.

The pre-operation check and inspection, performed at beginning of each work shift or at

each change of operator, should include the following:

1. Cleanliness - Check all surfaces for leakage (oil, fuel or battery fluid) or foreign

objects. Report any leakage to the proper maintenance personnel.

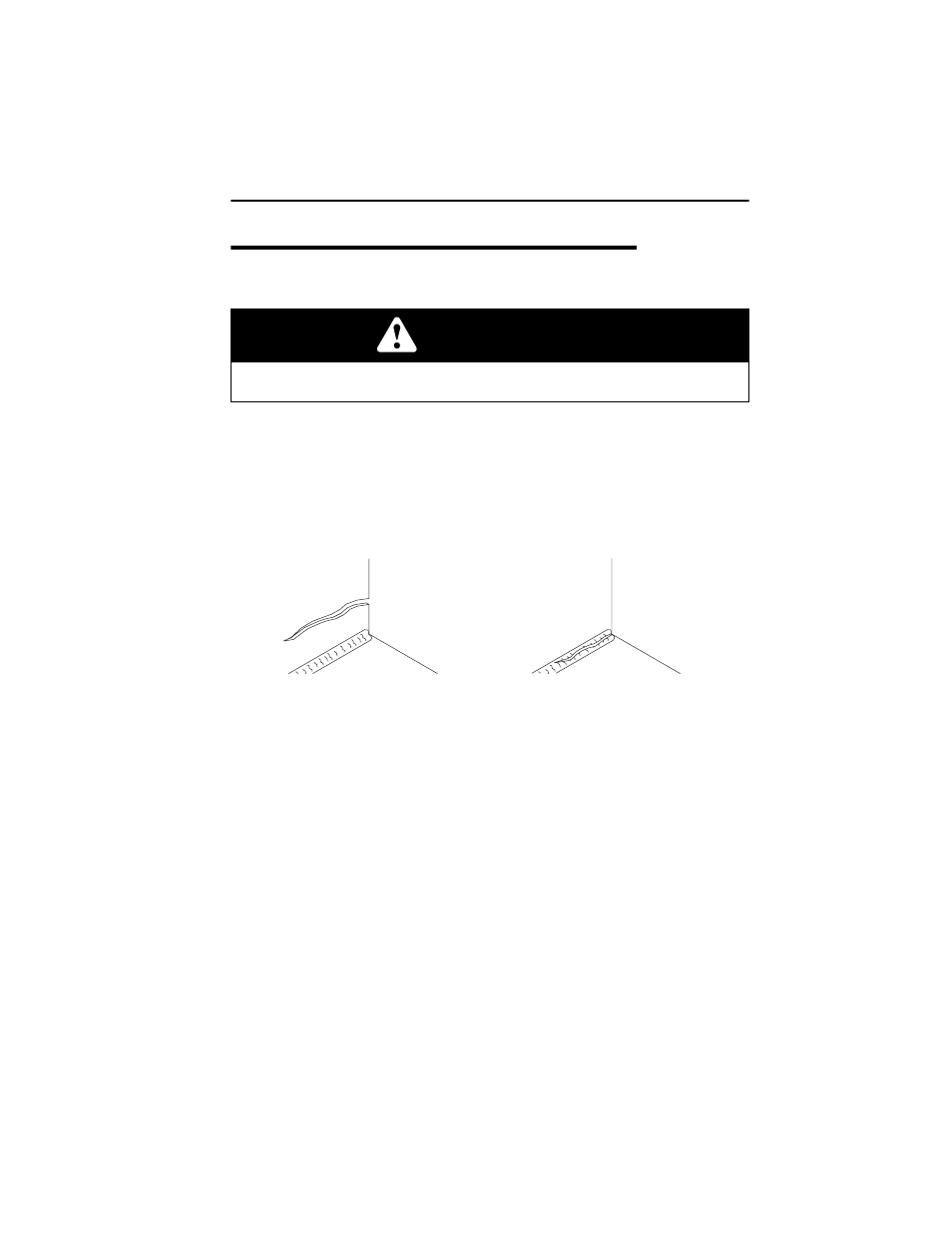

2. Structure - Inspect the machine structure for dents, damage, weld or parent metal

cracks or other discrepancies.

3. Safety Decals - Ensure all safety decals are legible and in place. Clean or replace as

required. See page 2-3 for details.

4. Operation and Safety Manuals - Operation & Maintenance Manual and AEM Safety

Manual (ANSI only) located in cab manual holder.

5. Walk-Around Inspection - See page 2-6 for details.

6. Fluid Levels - Check fluids, including fuel, hydraulic oil, engine oil and coolant. When

adding fluids, refer to Section 7 - Lubrication and Maintenance and Section

9 - Specifications to determine proper type and intervals. Before removing filler caps

or fill plugs, wipe all dirt and grease away from the ports. If dirt enters these ports, it

can severely reduce component life.

7. Attachments/Accessories - Ensure correct capacity charts are installed on the

telehandler. If provided, reference the Operation & Maintenance Manual of each

attachment or accessory installed for specific inspection, operation and maintenance

instructions.

WARNING

FALL HAZARD. Use extreme caution when checking items beyond your normal reach.

Use an approved ladder.

OAH1000

PARENT METAL CRACK

WELD CRACK