Hydraulic fluid temperature during operation, Maintenance and inspection, 6 periodic inspection and change criteria – JLG 600SC_660SJC Service Manual User Manual

Page 110: Hydraulic fluid, Filters, Periodic inspection and change criteria -18, Hydraulic fluid -18 filters -18

SECTION 5 - CAT CHASSIS (S/N 0300128000 TO PRESENT)

5-18

– JLG Lift –

3121157

Hydraulic Fluid Temperature during Operation

Temperature control of the hydraulic fluid is very important

in the hydraulic system. Higher temperature may degrade

the anti-oxidant resistivity and accelerate deterioration of

the hydraulic fluid. Therefore, take the following precau-

tions:

1.

Maintain the temperature during continuous opera-

tion within the range from +10 to +80 degree.

2.

Minimum start-up temperature should be at minus

+20 degree or higher. Maximum allowable tempera-

ture is +100 degree only for a short time (total accu-

mulative operating time under 100 degree should be

within 100h). These temperatures have been estab-

lished in consideration of degradation to viscosity

and anti-oxidant resistivity of the hydraulic fluid and

to the O-ring and oil seals. The motor life will be

shortened if the motor is continuously run at temper-

ature of +80 degree or higher.

Maintenance and Inspection

Perform maintenance and inspection of the motor for the

following check points unless a malfunction is detected:

1.

Is there any oil leakage at flange connections and

joints of the equipment?

2.

Is there any looseness in tightened bolts?

3.

Is there any damage on the appearance?

4.

Is there contamination in the lubricant?

5.6 PERIODIC INSPECTION AND CHANGE

CRITERIA

Hydraulic Fluid

Although the hydraulic oil is clean at first, it will be dirtied

with sediment such as sludge in the circuit and the tank

after a long operation, and it may cause damage to

hydraulic components. The hydraulic fluid will also be

degraded and will result in wear of the sliding compo-

nents. Therefore, it is necessary to check the hydraulic

fluid periodically and to change the fluid depending on the

state of degradation. However, it may be difficult to judge

quantitatively on site whether the fluid is degraded or not.

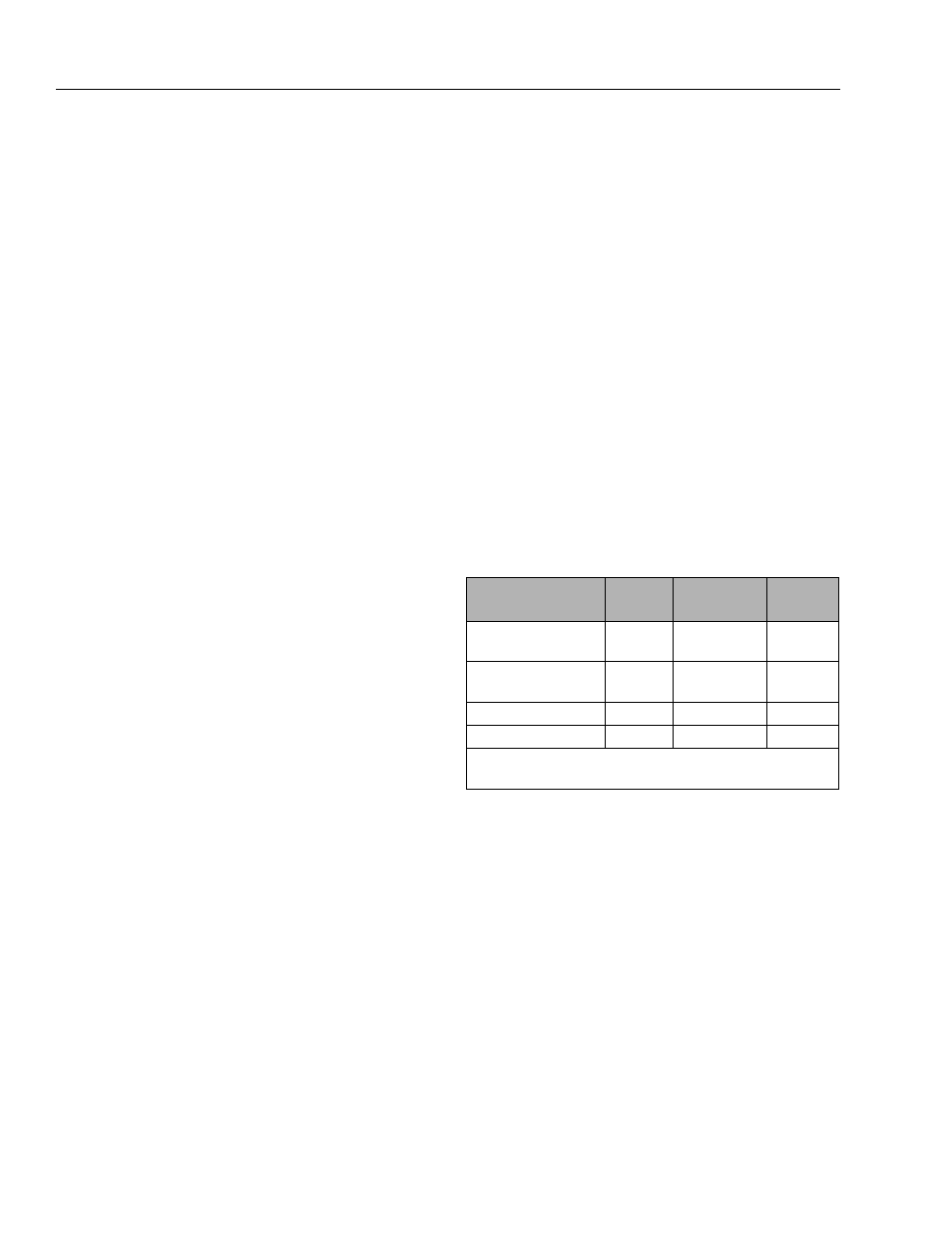

The following table is provided for information to be used

as a basis of visual inspection.

It is recommended to replace the oil with new after the first

500-hours of operation.

When hydraulic fluid is replaced, deposits such as deteri-

orated hydraulic fluid and sludge, and water are contained

in the circuit and tank. If left as they are, they will cause

operation failure of the motor and shorten its life-span. Be

sure to clean the tank and flush piping before replacing

with new hydraulic fluid.

Filters

Filtration effectivity is lowered if filter elements are

clogged. Periodic inspections are essential to maintain the

filters in good conditions.

Filters should be replaced with new ones after the first 50

hours of running, and checked after every 250 hours of

running. Where a differential pressure gauge is not pro-

vided, the filters should be replaced with new ones after

the first 50 hours and every 250 hours thereafter. The fil-

ters must be replaced with new ones when the hydraulic

fluid is replaced with new.

APPEARANCE *

SMELL

JUDGMENT

COUNTERM

EASURES

Transparent

(no discoloration)

Good

Good

Use as is

Transparent

(but dark spots are noted)

Good

Foreign sub-

stances mixed

Use after

filtration

Discolored (milky)

Good

Water contained Change oil

Discolored (darkish)

Bad

Oxidized

Change oil

* Visual Inspection Method

(Compare the old and new fluids in the test tubes)