Accessory usage guideline – Bryant SPLIT-SYSTEM 697C User Manual

Page 6

—6—

ACCESSORY USAGE GUIDELINE

* For tubing line sets between 50 and 175 ft, refer to Residential’s Split System Long-Line Application Guidelines.

† For buried line applications, refer to Residential’s Split Systems Buried Line Application Guidelines.

‡ Only when low-pressure switch is used.

ACCESSORY DESCRIPTION AND USAGE (Listed Alphabetically)

1.

Ball Bearing Fan Motor

A fan motor with ball bearings which permits speed reduction while maintaining bearing lubrication.

SUGGESTED USE: Required on all units where low-ambient controller (full modulation feature) or MotorMaster® Control has been added.

2.

Compressor Start Assist-Capacitor/Relay Type

Start capacitor and start relay gives “hard” boost to compressor motor at each start-up.

SUGGESTED USE: Installations where interconnecting tube length exceeds 50 ft. Installations where outdoor design temperature exceeds 105

°

F (40.6

°

C).

Replacement installations with hard shutoff expansion valve on indoor coil. Units installed with low-ambient controller. Units installed with liquid

solenoid valve.

3.

Compressor Start Assist-PTC Type

Solid-state electrical device which gives a “soft” boost to the compressor at each start-up.

SUGGESTED USE: Installations with marginal power supply.

Replacement installations with rapid pressure balance (RPB) expansion valve on indoor coil.

4.

Crankcase Heater

An electric resistance heater which mounts to the base of the compressor to keep the lubricant warm during off cycles. Improves compressor lubrication on

restart and minimizes chance of refrigerant slugging. May or may not include a thermostat control.

SUGGESTED USE: When interconnecting tube length exceeds 50 ft.

When unit will be operated below 55

°

F (12.8

°

C) outdoor air temperature. (Use with low-ambient controller.)

5.

Evaporator Freeze Thermostat

An SPST temperature actuated switch which stops unit operation when evaporator reaches freeze-up conditions.

SUGGESTED USE: With low-ambient controller.

6.

Filter Drier—Bi-flow

A device for removing contaminants from refrigerant circulating in a heat pump system; 2-direction flow for heat pumps.

SUGGESTED USE: Split-system heat pumps.

7.

Interface Control

An electric control for controlling a heat pump and gas or oil furnace system for maximum energy savings. It allows heat pump to operate down to a predeter-

mined economic balance point temperature, then switches to allow furnace operation only below that temperature. Requires outdoor thermostat (Item 12) to

be adjusted for economic balance point temperature.

SUGGESTED USE: For heat pump and gas- or oil-fired furnace combination systems.

8.

Isolation Relay

An SPDT relay which switches the low-ambient controller out of the outdoor fan motor circuit when the heat pump switches to heating mode.

SUGGESTED USE: All heat pumps where low-ambient controller has been added.

9.

Liquid Solenoid Valve (LSV)

An electrically operated shutoff valve to be installed at the outdoor unit and which stops and starts refrigerant liquid flow in response to compressor operation.

Maintains a column of refrigerant liquid ready for action at next compressor operation cycle.

SUGGESTED USE: In certain long-line applications. (Refer to Long-Line Application Guideline.)

10. Low-Ambient Controller

Head pressure controller is a cycle control device activated by a temperature sensor mounted on a header tube of the outdoor coil. It is designed to cycle the

outdoor fan motors in order to maintain condensing temperature within normal operating limits (approximately 130 to 110

°

F high, 70 to 50

°

F low). The control

will maintain working head pressure at low-ambient temperatures down to 0

°

F when properly installed.

SUGGESTED USE: Cooling operation at outdoor temperatures below 55

°

F (12.8

°

C).

11. MotorMaster® Control

A fan speed control device activated by a temperature sensor. Designed to control condenser fan motor speed in response to the saturated, condensing tem-

perature during operation in cooling mode only. For outdoor temperatures down to –20

°

F, it maintains condensing temperature at 100

°

F

±

10

°

F.

SUGGESTED USE: Cooling operation at outdoor temperatures below 55

°

F.

All commercial installations.

12. Outdoor Thermostat

An SPDT temperature actuated switch which turns on supplemental electric heaters when outdoor air temperature drops below set point.

SUGGESTED USE: Heat pump installations with multiple-stage supplemental heaters.

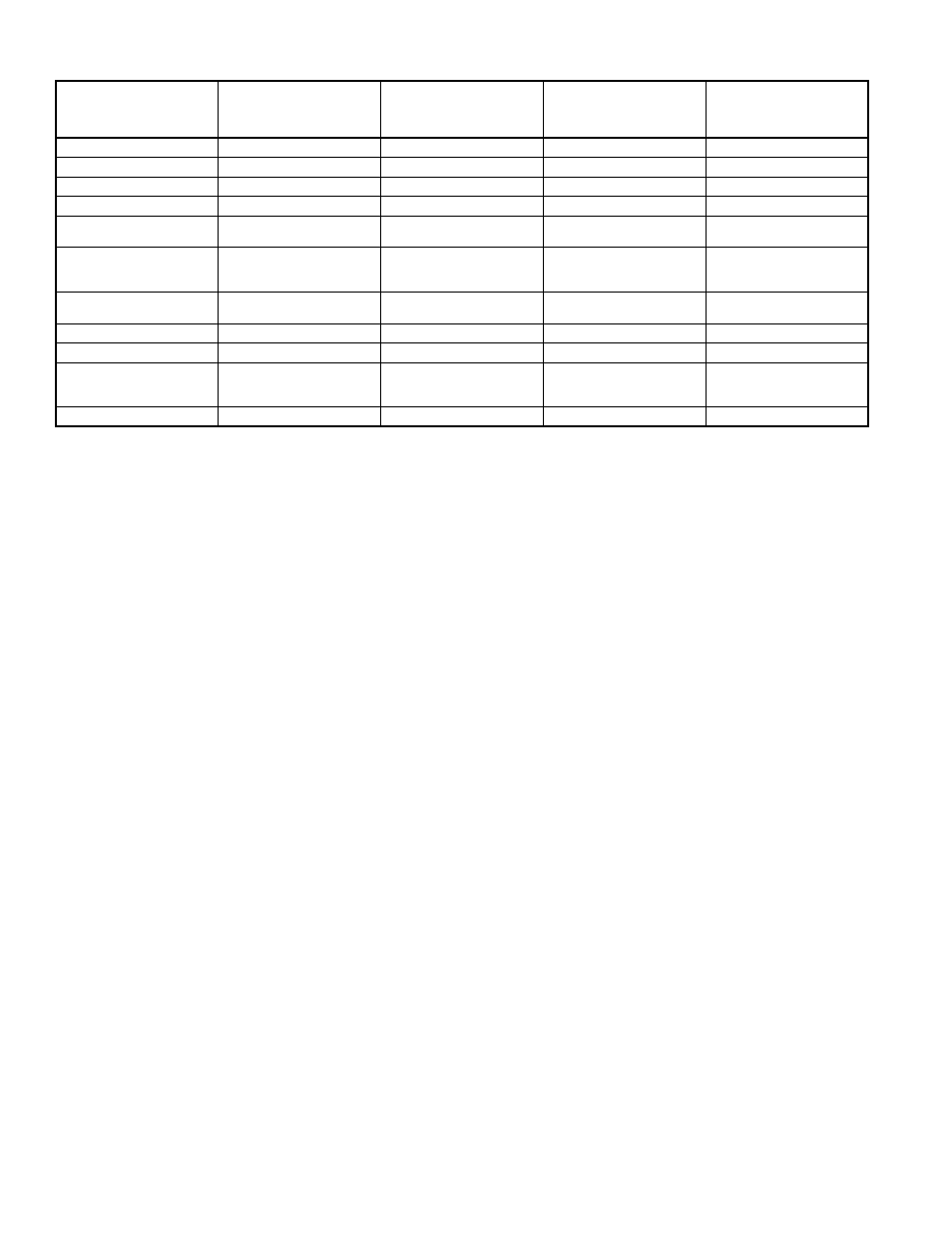

ACCESSORY

REQUIRED FOR

LOW-AMBIENT

APPLICATIONS

(Below 55

°

F)

REQUIRED FOR

LONG-LINE

APPLICATIONS*

(Over 50 Ft)

REQUIRED FOR

BURIED LINE

APPLICATIONS†

(Over 3 Ft)

REQUIRED FOR

SEA COAST

APPLICATIONS

(Within 2 Miles)

Crankcase Heater

Yes

Yes

Yes

No

Evaporator Freeze Thermostat

Yes

No

No

No

Winter Start Control

Yes‡

No

No

No

Accumulator

No

No

Yes

No

Compressor Start Assist

Capacitor and Relay

Yes

Yes

Yes

No

Low Ambient Controller

or

MotorMaster® Control

Yes

No

No

No

Wind Baffle

See Low-Ambient

Instructions

No

No

No

Coastal Filter

No

No

No

Yes

Support Feet

Recommended

No

No

Recommended

Liquid-Line Solenoid Valve

or

Hard Shutoff TXV

No

See

Long-Line

Application Guideline

Yes

No

Ball Bearing Fan Motor

Yes

No

No

No