Composite bearing installation -13, Rod seal installation -13, Cylinder head seal installation -13 – JLG 18RS Service Manual User Manual

Page 103

SECTION 5 - HYDRAULICS

3121284

– JLG Lift –

5-13

12.

Inspect cylinder head outside diameter for scoring or

other damage and ovality and tapering. Replace as nec-

essary.

13.

If applicable, inspect rod and barrel bearings for signs of

excessive wear or damage. Replace as necessary.

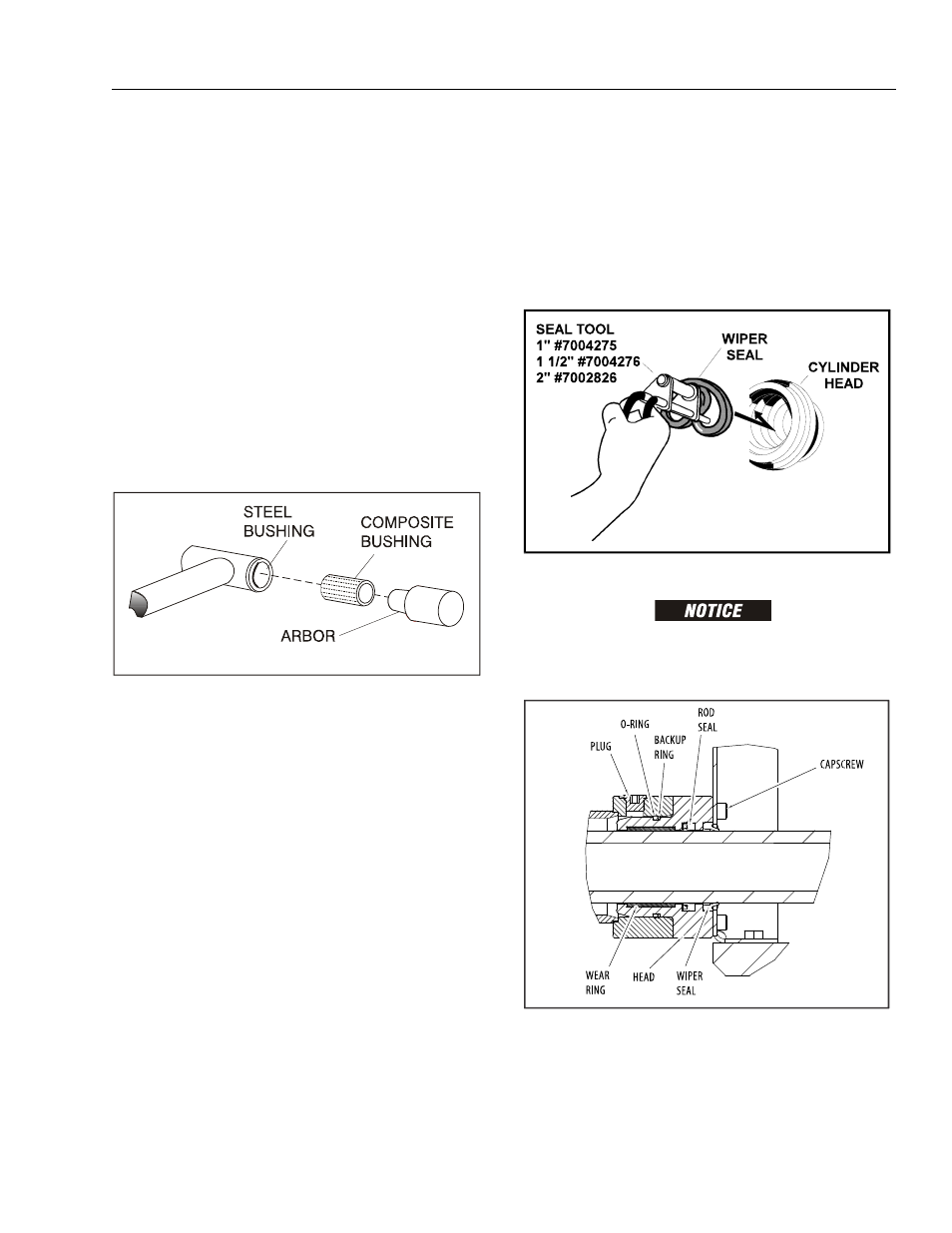

a. Thoroughly clean hole, (steel bushing) of burrs, dirt

etc. to facilitate bearing installation.

b. Inspect steel bushing for wear or other damage. If

steel bushing is worn or damaged, rod/barrel must

be replaced.

c. Lubricate inside of the steel bushing with WD40

prior to bearing installation.

d. Using an arbor of the correct size, carefully press the

bearing into steel bushing.

NOTE:

Install pin into the composite bearing dry. Lubrication is

not required with nickel plated pins and bearings.

14.

Inspect travel limiting collar or spacer for burrs and

sharp edges. If necessary, dress inside diameter surface

with Scotch Brite or equivalent.

15.

If applicable, inspect port block fittings and holding

valve. Replace as necessary.

16.

Inspect the oil ports for blockage or the presence of dirt

or other foreign material. Repair as necessary.

17.

If applicable, inspect piston rings for cracks or other

damage. Replace as necessary.

ASSEMBLY

NOTE:

Prior to cylinder assembly, ensure that the proper cylinder

seal kit is used. See your JLG Parts Manual.

Apply a light film of hydraulic oil to all components prior to

assembly.

1.

A special tool is used to install a new rod seal into the

applicable cylinder head gland groove.

W H E N I N S TA L L I N G N E W S E A L S , E N S U R E S E A L S A R E

INSTALLED PROPERLY. IMPROPER SEAL INSTALLATION

COULD RESULT IN CYLINDER LEAKAGE AND IMPROPER

CYLINDER OPERATION.

Figure 5-15. Composite Bearing Installation

Figure 5-16. Rod Seal Installation

Figure 5-17. Cylinder Head Seal Installation