2 motor, 3 triple eccentric drive, 7 electronic boards – Eppendorf Innova 2050 Digital Platform Shaker User Manual

Page 14: Motor, Triple eccentric drive, Electronic boards

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

14

3.6.2

Motor

The Innova 2000/2050 Shaker uses a brushless ball bearing DC motor. This low profile motor provides high

torque along with quiet, efficient operation and low maintenance. The motor has a rating of 1/20

horsepower.

3.6.3

Triple eccentric drive

The drive mechanism utilizes a counterweight system to stabilize the rotary motion produced during

operation. When the workload moves in one direction, opposing forces are generated to stabilize the

shaker. This action will help eliminate the problem of “walking” which may occur with less precisely

balanced instruments. Vibration is minimized and the life of the unit is extended.

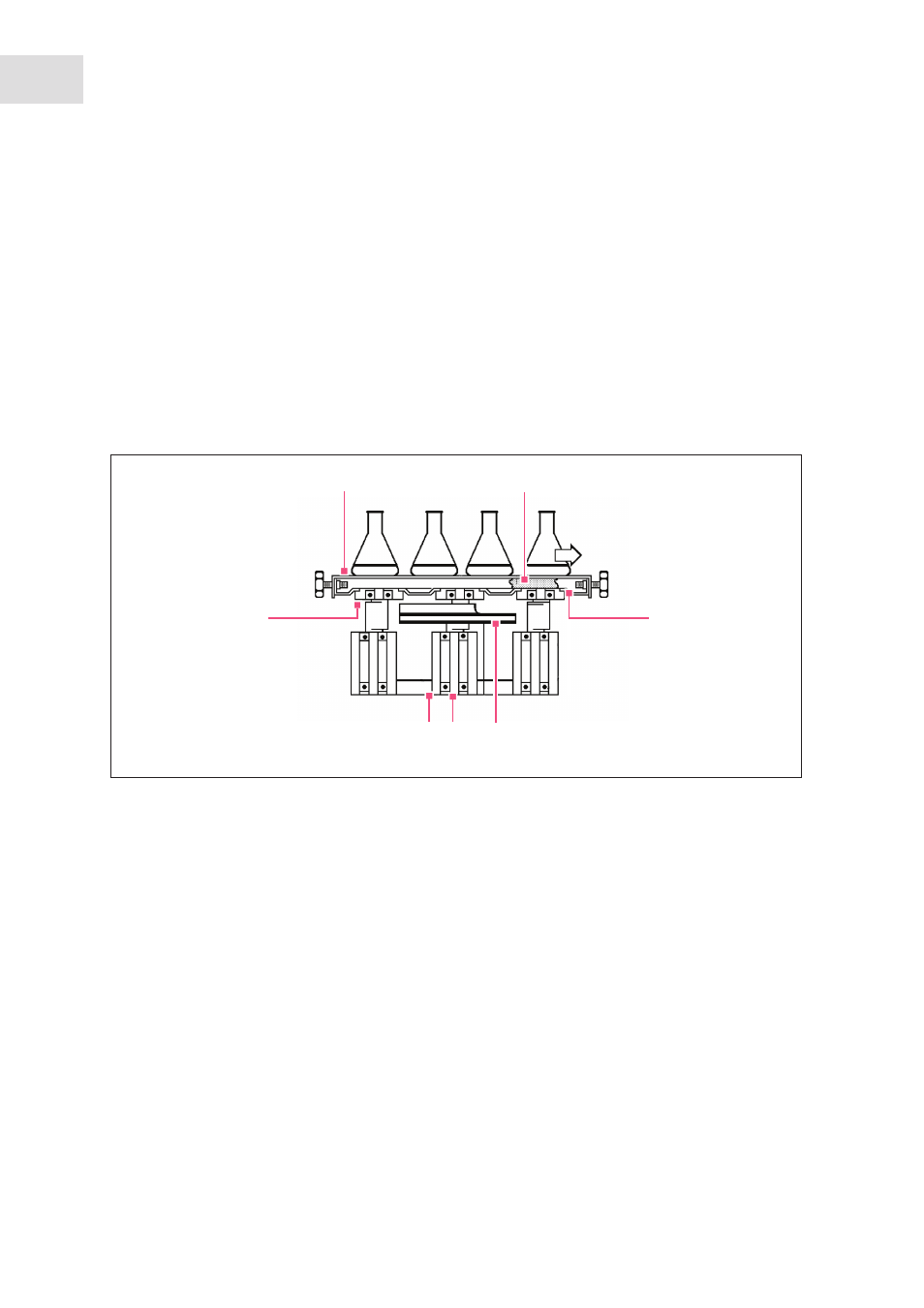

Abb. 3-4: Counterbalanced drive mechanism

Fig. 3-4:

Counterbalanced drive mechanism

3.7

Electronic boards

The main control board for Innova shakers has the following functions:

• Non-volatile memory for storage of key parameters during power interruption;

• Speed sensing, electronic commutation, and power control for the brushless DC drive motor;

• Maintains an elapsed running time clock;

• Contains firmware for shaker control as well as recognition of an expansion connector for option

1

Platform

2

Spongepad

3

Sub-platform

4

Pulley with counterweight

5

Eccentric drive shaft

6

Lower bearing housing

7

Upper bearing housing

1

2

3

7

4

5

6