Impellers, Propeller fans, Centrifugal fans – Aerovent IM-101 User Manual

Page 2

ine alignment, complete the assembly, and lubricate the

coupling (when required) before putting the unit into

operation.

Impellers

Fans, which are received factory assembled, have the impellers

already aligned and in place before shipment. However, fans

being flexible to some extent are sometimes subject to move-

ment during shipment. To insure smooth operation and

proper performance, the following impeller alignment should

be checked before putting fan into operation.

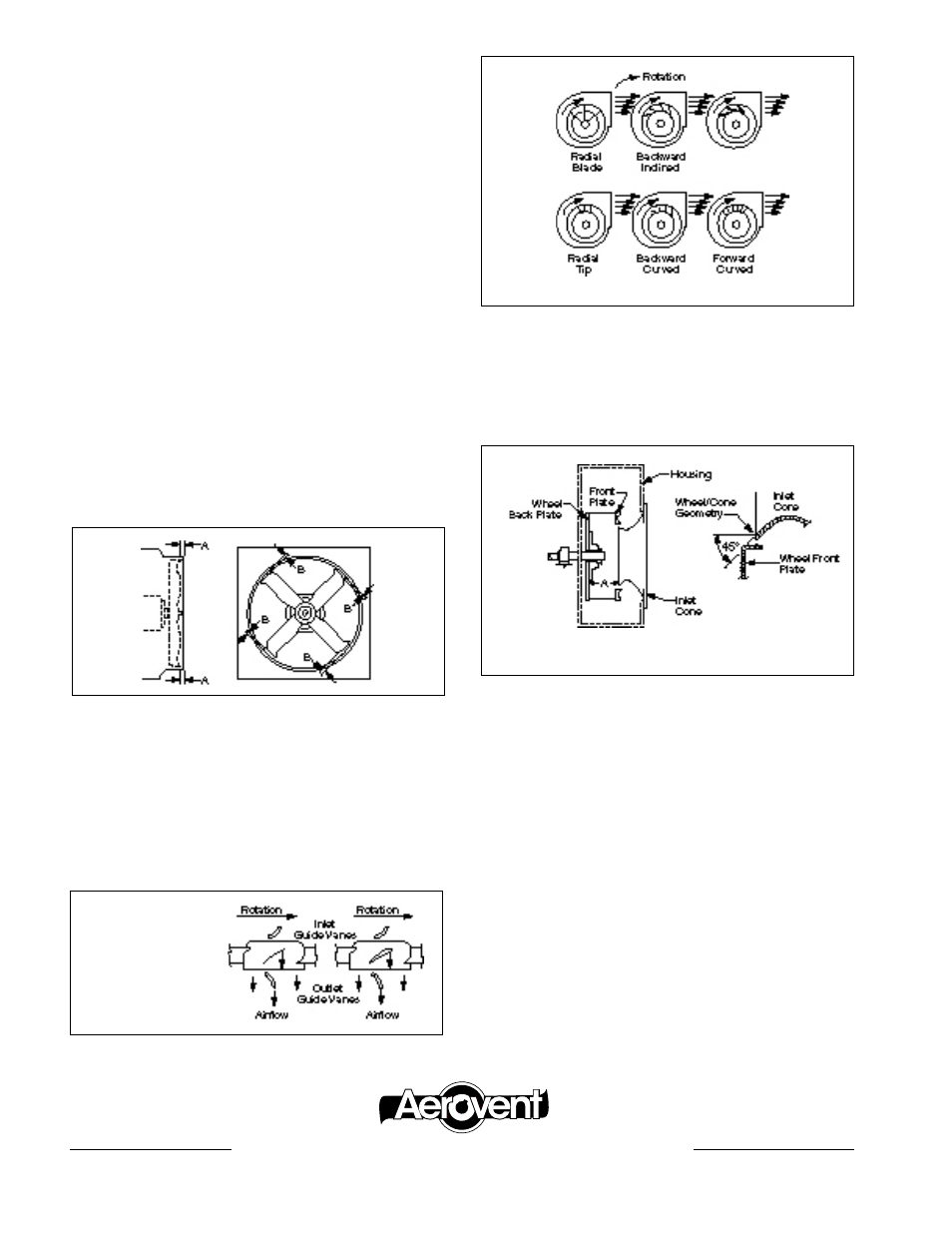

Propeller Fans

Fan shaft should be centered and parallel to fan casing. Center

by checking gap (B) between propeller tip and fan casing.

Repeat at three additional points at approximately 90° from

each other (Figure 3b). Parallelism can be observed by measur-

ing the axial distance (A) from one blade to the end of the fan

casing at four points at approximately 90° from each other

(Figure 3a).

Do not confuse parallelism with blade track (axial deviation

of one blade to another). Blade track can be checked by mea-

suring the axial distance from one point on the fan casing to

the same point on each blade as it passes by. (Some blades are

mistracked for balancing.)

While checking the propeller alignment, it is good practice

to check its rotation. Normally the fan rotation is marked by

arrows on both the propeller and the fan casing. If omitted,

obliterated, or misapplied, check for proper rotation in Figure

4a.

Centrifugal Fans

The fan shaft should be approximately centered in the clear-

ance hole in the fan housing and perpendicular to the housing

sides. Perpendicularity can be checked on BI and BIA fans by

measuring dimension “A” (Figure 5) at four points approxi-

mately 90° apart.

Radial blade impellers, material handling, pressure blowers,

and high pressure blowers are centered axially in the housing,

and can be checked by measuring the axial distance from one

blade or one point on the front plate to the side of the fan

housing at four points approximately 90° from each other.

While checking the impeller alignment, it is good practice

to check its rotation. Normally the fan rotation is marked by

arrows on the housing. If omitted, obliterated, or misapplied,

check for proper rotation in Figure 4b.

Figure

3a

Figure

3b

Figure 4a

RH rotation.

Vaneaxial shown.

Standard propellers

similar, but less guide

vanes.

Figure 4b

Figure 5

NOTE: See IM-140 for dimensions.

6MWG09/10

Aerovent | www.Aerovent.com

5959 trenton Lane n | minneapolis, mn 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

®