Care and maintenance, Filters and filter care, Filter maintenance – Aerovent IM-135 User Manual

Page 2: Disposable filters

Care and Maintenance

The filtered air supply unit requires a minimum of attention to

keep it operating properly. However, a certain amount is

required to prolong its most efficient operation. The compo-

nents requiring service are generally the moving parts which

include bearings, propeller, belts and sheaves, motor and shut-

ter. The maintenance for all of these items, with the exception

of the propeller and filters, is covered in a separate installation

and maintenance manual included with this shipment. Good

fan maintenance requires regular and systematic inspection of

all fan parts. Severity of the application should determine fre-

quency of inspection and fan maintenance should include the

following:

1.

PROPELLER: When the fan wheel is handling clean air,

as in the case of the filtered air supply unit, dirt build-up

will be slight and very little unbalance will result. Air heav-

ily laden with grease and dirt will deposit a great deal on

propeller blades. Conditions should be observed and clean-

ing performed as required for smooth fan operation and, in

the case of grease, removal of this fire hazard.

One problem that often develops is the unbalance

which occurs when particles of dirt and grease build up on

the blades. This unbalance condition will naturally cause

wear and noise. Cleaning should be accomplished, if pos-

sible, without removing the propeller from the shaft.

2.

V-BELT DRIVE: Check V-belt drive for proper align-

ment and tension. (See General Installation and Maintenance

Manual, IM 100.)

3.

FAN BEARINGS: Lubricate the bearings as detailed in

the ball bearing lubrication instructions. (See General

Installation and Maintenance Manual, IM 100.)

4.

SCREWS AND BOLTS: Check tightness of all screws

and bolts throughout the assembly.

5.

SHUTTERS: Periodically check damper blades and

remove accumulated dirt. Also, check bronze damper bear-

ings and motor linkage for smooth operation.

Filters and Filter Care

The standard filters furnished with the Aerovent filtered air

supply unit are permanent washable type and are designed for

a face velocity of 520 feet per minute. These may be 16x20x2

inch, 16x25x2 inch or 20x25x2 inch.

Filters must be cleaned regularly to prevent undue resis-

tance and a loss of filtering efficiency. Manometers and other

warning devices are available to indicate when the filters are

clogged but visual inspection at regular intervals is probably

the best method for determining when it is time to clean and

change filters. These filters can be removed with the hood in

place.

Filter Maintenance

Remove and flush filter with water containing ordinary deter-

gent. Rinse with clean water. Drain and allow to dry. Then

recoat the filter with filter coat adhesive such as RP Super

Filter Coat Adhesive (Research Products Corporation,

Madison, Wisconsin). Never replace these washable type fil-

ters without coating.

Disposable Filters

Aerovent supplies two types of disposable filters. One has a

permanent metal frame with disposable media and the other,

Farr 30-30, has a treated fiber frame which is completely dis-

posable. Ordinary “throwaway” filters with a paper frame and

face retainer tend to deteriorate from moisture, thereby caus-

ing the filters to fall out of the frame.

A permanent washable filter may be replaced with dispos-

able type provided that the manufacturer’s specifications call

for a face velocity of 520 feet per minute and are of the same

size and thickness.

In many cities, professional filter cleaning and replacement

service is available. This is often a convenient and economical

arrangement for filter care.

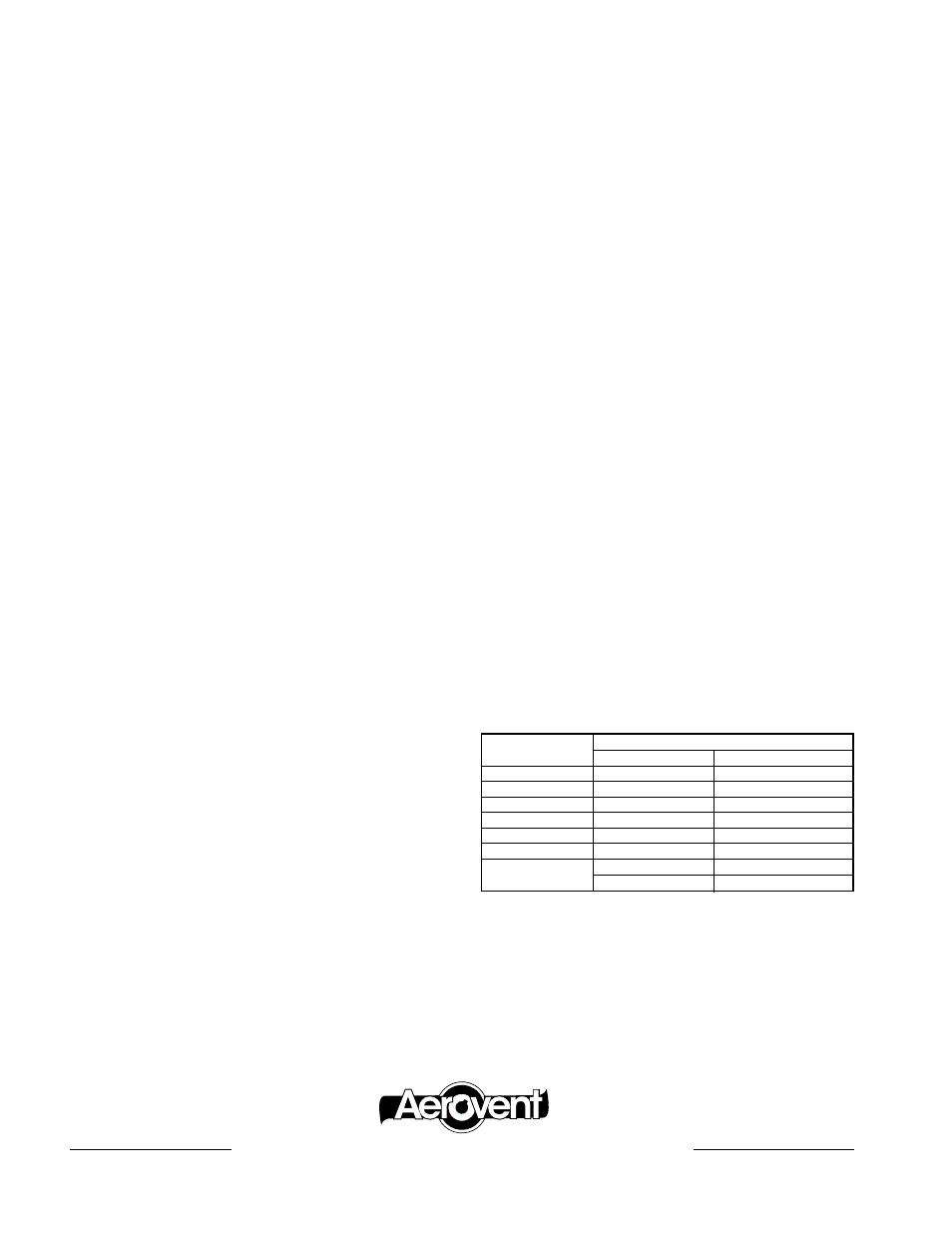

FILTERS

FAN SIZE

NO.

SIZE

24

8

16 x 20 x 2

30

14

16 x 20 x 2

36

22

16 x 20 x 2

42

22

16 x 25 x 2

48

28

16 x 25 x 2

54

44

16 x 20 x 2

12

20 x 25 x 2

60

28

16 x 25 x 2

2MSS3/01

Aerovent | www.Aerovent.com

5959 trenton Lane n | minneapolis, mn 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

®