Installation instructions, Checking bushing torque, Removing propeller assembly from shaft – Aerovent IM-171 User Manual

Page 2

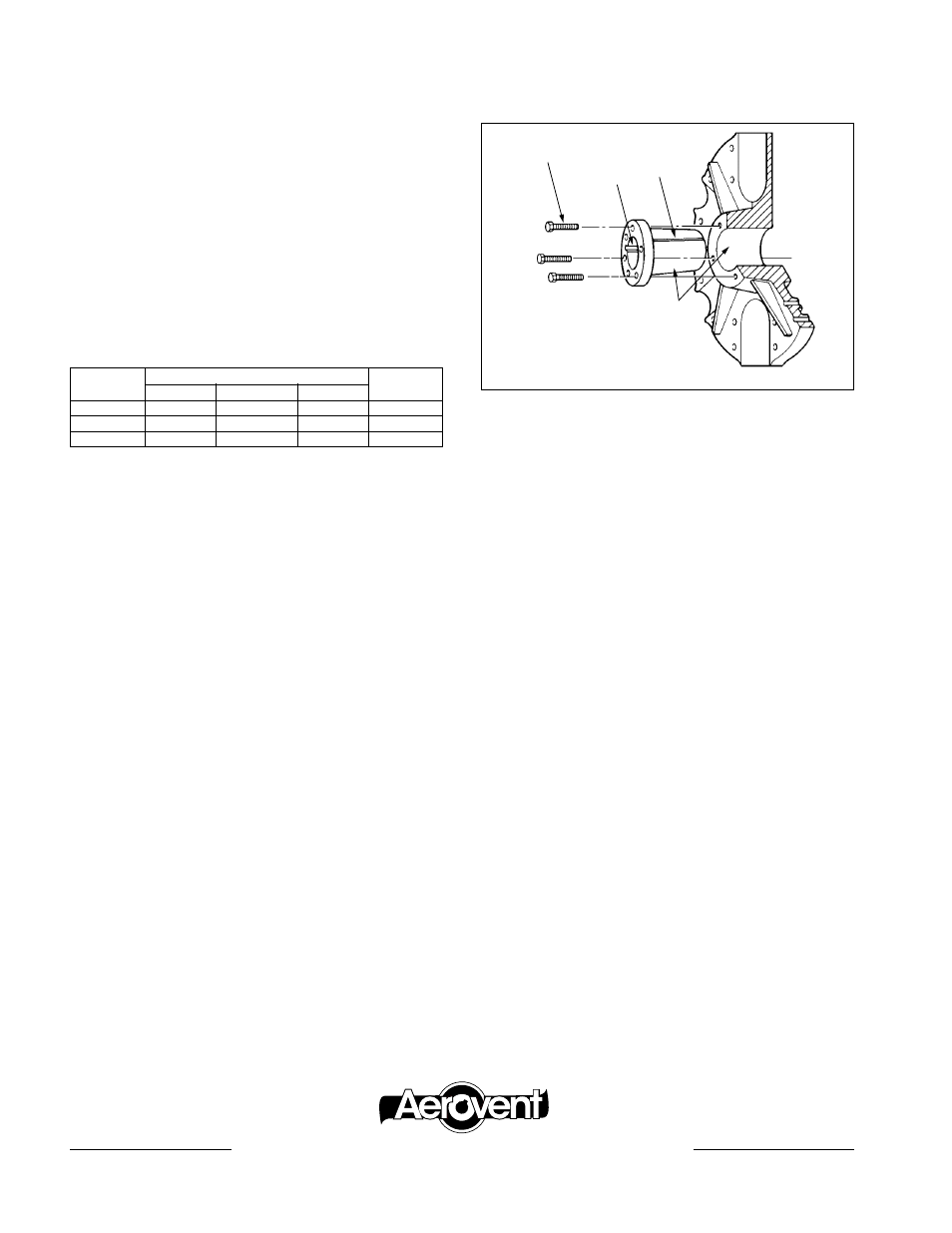

Aerovent adjustable pitch propellers are furnished with

hubs that have a tapered bore. A split taper bushing

is used for mounting the propeller assembly to the

shaft. When properly assembled, the bushing grips

the hub and the shaft with a positive clamping action.

The split taper bushing is always mounted on the

discharge or cap side of the hub unless the propel-

ler has been ordered with a reverse bore.

A. Bushing barrel and bore of propeller hub are

tapered. This assures concentric mounting and a

true running propeller.

B. Capscrews, when tightened, lock bushing in pro-

peller. Use plated capscrews threaded full length

(see table below).

BUSH

CAPSCREW

TORQUE

NO.

SIZE

THREADS/IN

LENGTH

(FT/LBS)

Q2

3

⁄

8

"

16

2

1

⁄

2

"

24

R2

3

⁄

8

"

16

3"

24

P2

5

⁄

16

"

18

3

3

⁄

4

"

13

C. Bushing is split so that when the locking cap-

screws force bushing into tapered bore, the bush-

ing grips the shaft with a positive clamping fit. This

will withstand vibration and punishing loads without

being loosened.

D. Propeller and bushing assembly is keyed to shaft

and held in place by compression. This gives

added driving strength.

Installation Instructions

Put bushing loosely into propeller. Do not press or

drive. Start capscrews by hand, turning them just

enough to engage threads in tapped holes on propel-

ler. Do not use a wrench at this time. The bushing

should be loose enough in the propeller to move

slightly.

Be sure shaft and keyway are clean and smooth.

Check key size with both shaft and bushing keyways.

Slide propeller and bushing assembly onto shaft,

making allowance for end play of shaft to prevent

rubbing. Do not force propeller and bushing onto

shaft. If it does not go on easily, check shaft, bush-

ing and key sizes.

Tighten capscrews progressively with wrench. Do

this evenly as in mounting an automobile wheel. Take

a part turn on each capscrew successively until all

are tight.

These capscrews force the taper bushing into the

hub which in turn compresses the bushing onto the

shaft. This makes a positive clamping fit. The torque

must not exceed the torque values shown in the

chart to the left.

WARNING: Do not attempt to pull bushings flange

flush with hub end. There should be

1

⁄

8

" to

1

⁄

4

" clear-

ance when tightened.

Checking Bushing Torque

On kiln installations, it is necessary to check the

bushing bolt torque after start-up. Torque the bolts

after any initial run-in period and after the first 24

hours or first run of lumber through the kiln.

Tightening of the bolts while the assembly is still

warm from the kiln heat will help to maintain proper

torque. Periodic checking of torque on a regular

maintenance schedule is recommended.

Removing Propeller Assembly From Shaft

1. Remove all three capscrews from propeller and

hub assembly.

2. Start capscrews into the threaded holes in the

bushing flange.

3. Tighten each bolt part of a turn successively to

force the propeller off the bushing.

4. Pull the bushing off the shaft. If the assembly has

been in place some time, it may be necessary to

use a wheel puller to remove the bushing. Never

use a wheel puller on the propeller.

For propeller dimensions, see drawing B8709B.

Installation Instructions For Propellers Equipped With

Browning Malleable Iron Split Taper Bushings

B

D

C

A

DO NOT LUBRICATE

CAPSCREWS, BORE,OR

BUSHING BARREL.

Aerovent | www.Aerovent.com

5959 trenton Lane n | minneapolis, mn 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

®