Tf tubeaxial and vtf vaneaxial, Bearing housing, General maintenance – Aerovent IM-175 User Manual

Page 2

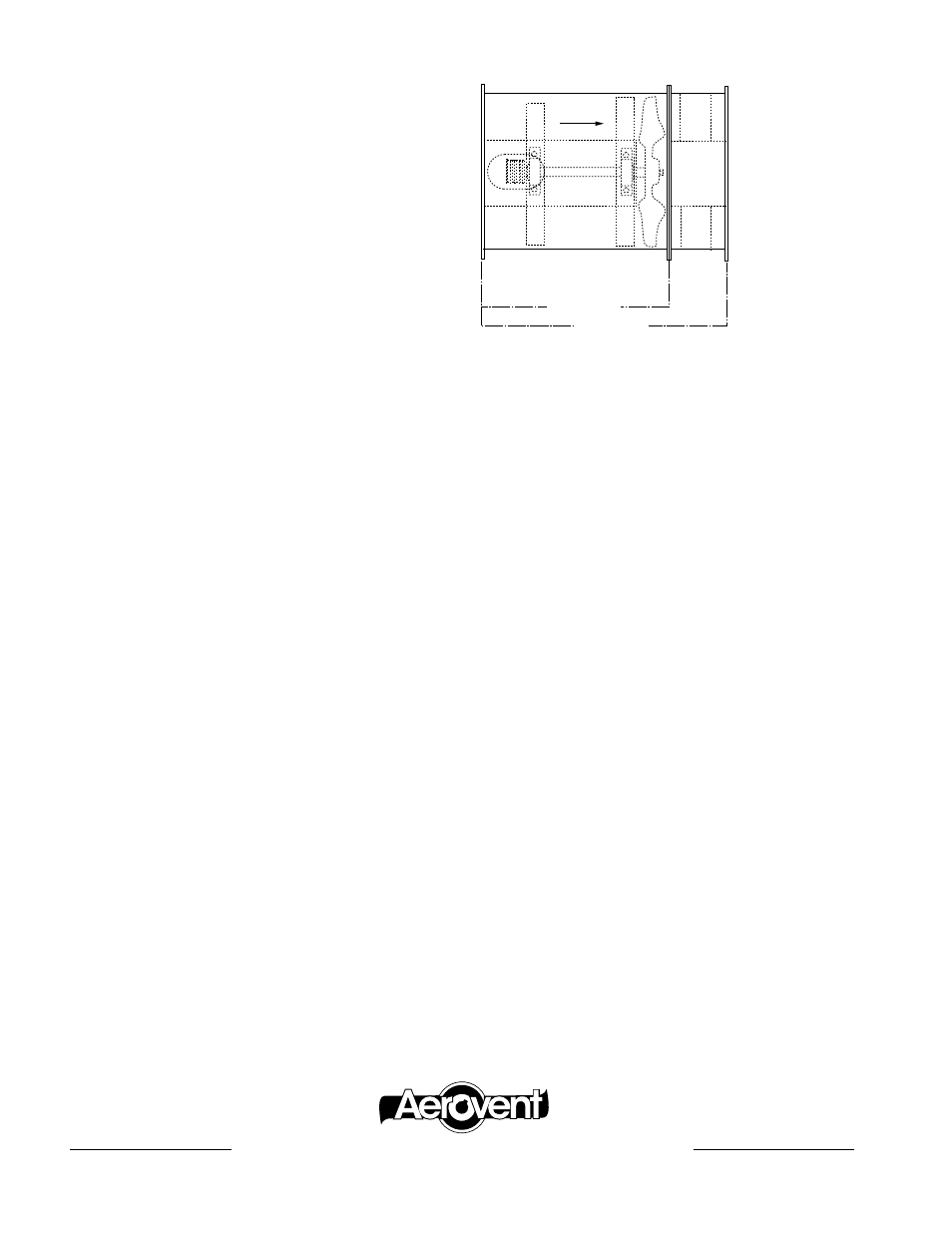

The installation of “TF” type fiberglass fans requires the same

considerations as previously outlined for the FG7 tubeaxial

fans with regard to support and bracing. The “TF” tubeaxial,

since it has no vane section or access door, should be mounted

so that it is easily removable for cleaning. In the case of a

“VTF” vaneaxial fan, the separate guide vane section may be

removed which will allow access to the impeller for cleaning.

TF Tubeaxial and VTF Vaneaxial

Guide

Vane

Section

Tubeaxial (TF)

Vaneaxial (VTF)

Airflow

Bearing Housing

The bearings on FRP fans are enclosed in a fiberglass cover to isolate them from the airstream. Grease lines are corrosion resistant

and are extended out through the belt housing to be accessible from the motor side of the fan. The bearings should be lubricated

according to the operating conditions of the fan described in that section of the general installation and maintenance manual

(IM-100) covering bearing lubrication. The cover enclosing the bearings and the driven sheave have been secured and sealed in

place, and a shaft seal has been provided to give as complete a seal as possible. To service or replace bearings, it is necessary to first

remove the impeller from the shaft and then remove the shaft seal. Remove the screws and nuts holding the cover onto the mount-

ing surface. With a knife, cut the sealant (gray colored material) until a thin wedge (putty knife) can be used to shear the sealant

material. Avoid prying on flange of bearing cover. After the sealant has been broken loose all around the joint, the cover can be

easily removed exposing the bearings for service. Before replacing bearing cover, remove the hardened sealant from the flange and

from the support. Lay a bead of Dow Corning 780 Building Sealant onto flange or bearing cover and complete the re-assembly.

General Maintenance

Fiberglass tubeaxial, vaneaxial fans and roof ventilators require a regular and systematic inspection of all fan parts. A general instal-

lation and maintenance manual (IM-100) has been supplied with this shipment which includes fan and motor bearing lubrication

instruction and care and replacement of V-belt drives. Regular maintenance on fiberglass fans should include the following:

1.

PROPELLER: The propeller in an FRP axial-flow fan must be kept reasonably clean if it is to perform properly. Dirt or

chemical deposits will usually build up on a propeller evenly and they present no problem to performance or operation until they

become thick enough to break away in crust-like pieces. When this happens, the propeller may be thrown out of balance and

the resulting vibration could be serious. When removing this crustaceous accumulation, care should be taken not to clean the

propeller with sharp objects which might damage the laminated surface and reduce corrosion resistance. Should the propeller

show excessive wear, it should be replaced.

2.

GUIDE VANES: Should be cleaned at the same time as the propeller. The guide vanes are important to the performance of

the fan and these particularly should be inspected.

3.

V-BELT DRIVE: Check for proper alignment and tension. (See General Installation and Maintenance Manual Bulletin 101

for instructions.)

4.

FAN BEARINGS: Lubricate the bearings as detailed on page 3 of the General Installation and Maintenance Manual. (IM-100).

5.

DAMPERS: On roof ventilators, periodically check damper blades and remove accumulation of foreign material.

6.

SCREWS AND BOLTS: Check for tightness throughout the assembly.

Aerovent | www.Aerovent.com

5959 trenton Lane n | minneapolis, mn 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

®