Wheel clearance, Maintenance, Type bw, ow, pb & hpb – Aerovent IM-140 User Manual

Page 2: Type aw, Type fc, Type biub

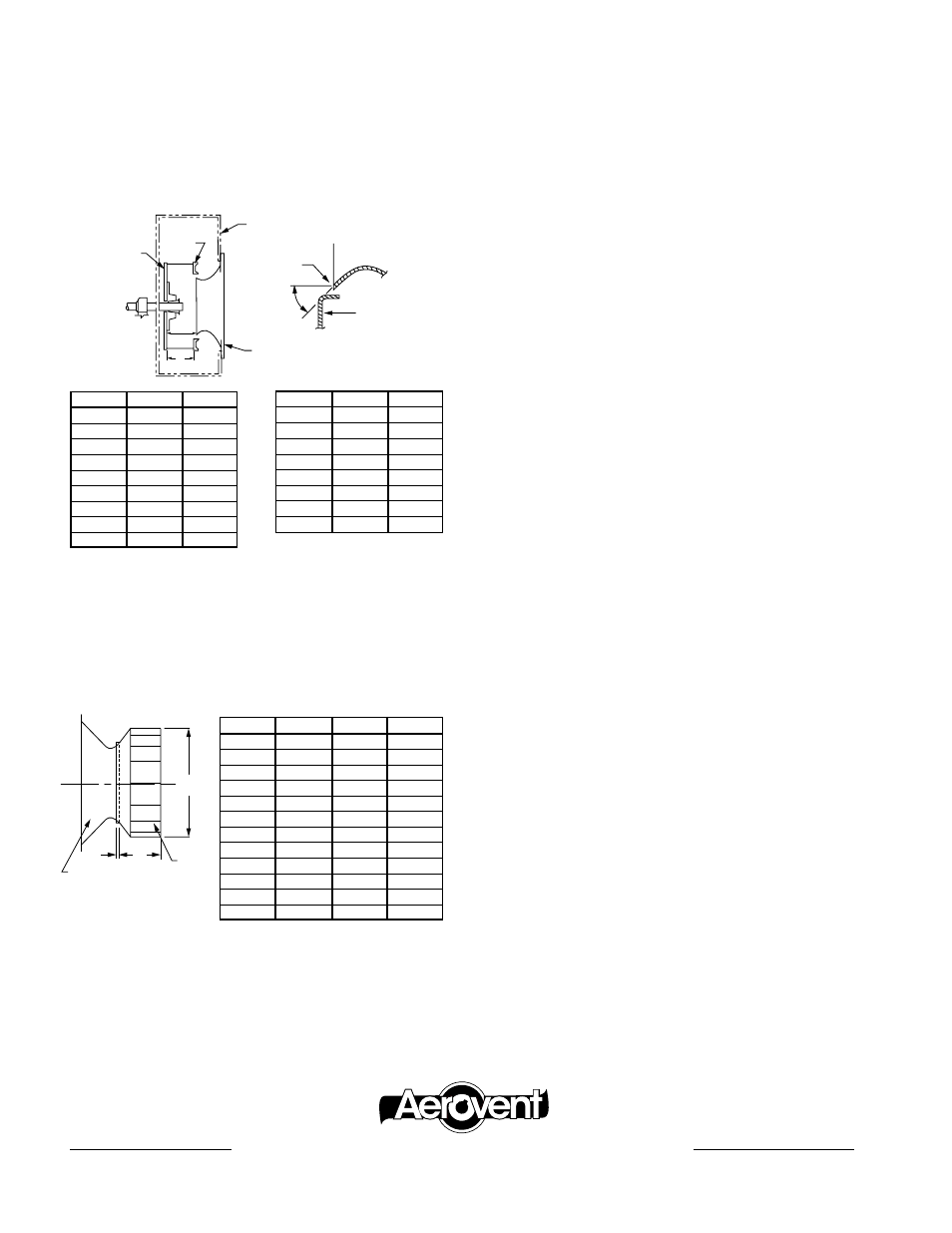

Wheel Clearance

Adjust clearance by moving the wheel axially on the shaft. The

following table indicates the correct measurements for position-

ing the BI and BIA wheels. Proper positioning is important in

attaining correct fan performance, particularly on the BI and

BIA wheels.

Type BW, OW, PB & HPB

These radial blade wheels do not require precise positioning

to attain the correct performance. The important thing is to

centrally locate these wheels axially within the housing to ensure

adequate running clearance and to maintain concentricity with

the fan inlet.

Type AW

These wheels require a special inlet on the housing which must

extend into the wheel inlet flange to perform properly. Other

than maintaining a minimum

1

∕

4

" overlap, adequate running

clearance and concentricity are all that is required.

Type FC

The forward curve blower employs a shallow venturi in the

housing to guide the air into the wheel. The depth of this ven-

turi is approximately one-tenth the wheel diameter. Clearance

between the wheel and venturi should be the smallest allowable

and still maintain normal running clearance. This axial separa-

tion is approximately

1

∕

4

" and should be measured at four points

approximately 90° apart.

Maintenance

Regular and systematic inspection of all fan parts is the key to

good fan maintenance. Frequency of inspection is determined

by the severity of the application and local conditions. Once a

maintenance schedule is established, it should be strictly fol-

lowed. Regular fan maintenance should include the following:

1. Check fan wheel for any build-up of foreign material or

excessive wear from abrasion. Both can cause vibration

which creates a serious safety hazard. Any build-up of for-

eign material should be removed. If the wheel shows exces-

sive wear, replace it immediately.

2. On belt driven units, check V-belt drive for proper alignment

and tension. If belts show wear, they should be replaced with

a matched set of belts. If unit is direct driven, check coupling

alignment.

3. Lubricate the bearings (see bearing section for lubrication

specifications). On direct drive units, lubricate the coupling

(see coupling section).

4. Lubricate shaft seal with the same grease as used on the fan

bearings. IMPORTANT: The operating life of the shaft seal

is dependent upon the amount and frequency of lubrication.

Insufficient grease in the shaft seal may result in damage to

the seal and reduced sealing efficiency.

5. A final check on the tightness of all setscrews and bolts

completes the maintenance routine.

SIZE

A

W*

12

4

11

/

16

4

7

/

16

14

5

9

/

32

5

1

/

32

16

5

29

/

32

5

21

/

32

18

6

23

/

32

6

3

/

8

20

7

7

/

16

7

1

/

16

22

8

5

/

16

7

15

/

16

25

9

5

/

16

8

15

/

16

28

10

17

/

32

10

1

/

16

32

11

27

/

32

11

11

/

32

SIZE

A

W*

35

13

15

/

16

12

3

/

4

39

14

27

/

32

14

3

/

16

44

16

9

/

16

15

7

/

8

49

18

9

/

16

17

23

/

32

55

20

7

/

8

19

27

/

32

63

23

3

/

4

22

11

/

16

71

26

19

/

32

25

1

/

2

79

29

5

/

8

28

11

/

32

Wheel Front

Plate

Inlet

Cone

Wheel/Cone

Geometry

Housing

45°

Inlet

Cone

Front

Plate

Wheel

Back Plate

A

W

*100% Wheel Width

“A” dimension (inside edge of inlet cone to inside face of

wheel backplate) must be held. This dimension is critical to fan

performance. “A” dimension shown is based on 100% wheel

width “W” and must be adjusted if wheel furnished is other

than 100% full width.

Type BIUB

B

A

DIA.

C

Inlet Cone

Wheel

SIZE

A

B

C

12

12.25

0.32

4.28

13

13.50

0.34

4.84

15

15.00

0.38

5.38

16

16.50

0.44

5.81

18

18.25

0.56

6.44

20

20.00

0.63

7.00

22

22.25

0.69

7.84

24

24.50

0.75

8.63

27

27.00

0.88

9.47

30

30.00

0.97

10.56

33

33.00

1.06

11.63

36

36.50

1.10

13.03

3MSE09/09

Type BI & BIA (SWSI Units)

Aerovent | www.Aerovent.com

5959 trenton Lane n | minneapolis, mn 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

®