Maintenance, Warning – Aerovent IM-632 User Manual

Page 4

4

Aerovent IM-632

Maintenance

Installation and maintenance are to be performed only

by qualified personnel who are familiar with local codes

and regulations and experienced with this type of equip-

ment.

CAUTION: Sharp edges and screws are a potential injury

hazard. Avoid them.

WARNING

Hazardous moving parts. Unit may contain pro-

tected fan motor which may start automatically

and cause injury. Allow time for reset.

Disconnect

power before servicing.

Preventive maintenance is the best way to avoid unnec-

essary expense and inconvenience. Start-up and routine

maintenance should cover the following items:

a. Tighten all setscrews, bolts and wire connections.

b. Check belt tension and sheaves for wear.

c. Lubricate fan bearings (see Tables 1 and 2).

d. Cleaning of unit, propeller and damper (if present).

All motors containing ball bearings are permanently

lubricated from the factory. No additional maintenance

is required.

1. Before performing any maintenance on the fan, be

sure power is turned off and locked in the OFF

position at the service entrance.

2. Ventilators should be carefully checked at least once

a year. For critical or rugged applications, a routine

check every two or three months is suggested.

3. For repairs within the warranty period, the motor

must be taken to the motor manufacturer’s autho-

rized service dealer.

4. A periodic motor check should consist of spinning

the motor shaft with the power off to be sure the

motor turns freely and the bearings run smoothly.

The belt on belt driven units should be removed

from the motor sheave.

5. When removing or installing a belt, do not force the

belt over the sheave. Loosen the motor mount so

that the belt can be easily slipped over the sheave.

(For Notes 5-9, refer to page 6.)

6. The belt on belt driven units should be removed and

carefully checked for glazing, cracks, ply separation

or irregular wear. A small irregularity in the contact

surface of the belt will result in noisy operation. If

any of these defects are apparent, the belt should

be replaced. Check the sheaves also for chipping,

dents or rough surfaces which could damage the

belt.

7. The correct belt tension is important. Too tight of

a belt will result in excess bearing pressure on the

motor bearings and shaft pillow blocks and may

also overload the motor. Too loose of a belt will

result in slippage which will quickly “burn” out belts.

A belt should feel “live” when thumped, approxi-

mately

1

⁄

4

" belt deflection (3 to 5 lb.) when subject

to finger pressure at midpoint between sheaves.

8. The belt alignment should also be checked to

be sure the belt is running perpendicularly to the

rotating shafts. Fan and motor shafts must be

parallel. Improper alignment will result in excessive

belt wear.

9. Check sheave setscrews to ensure tightness. Proper

keys must be in keyways.

10. For blade angle adjustments on Type 'E' Propellers

(Level 3), refer to Engineering Supplement ES-404.

11. If unit is to be left idle for an extended period, it is

recommended that belts be removed and stored in

a cool, dry place to avoid premature belt failure.

12. The standard pillow block bearings on belt driven

ventilators are factory lubricated and are provided

with external grease fittings. Annual lubrication is

recommended, or more frequently if needed (see Table 1).

It is recommended to add fresh grease at start-up. Use

only 2 or 3 shots of a recommended lubricant with

a hand gun in most cases (see Table 2). Maximum

hand gun rating 40 P.S.I. Rotate bearings during

lubrication where good safety practice permits.

CAUTION: Greases of different soap bases (lithium,

sodium, etc.) may not be compatible when mixed.

Prevent such intermixing by completely purging the

bearing of old greases.

The most frequent causes of bearing failure are not

greasing often enough, using an excessive quantity

of grease or using incompatible greases. Excessive

vibration, especially if the bearing is not rotating, will

also cause bearings to fail. Bearings must also be

protected from water and moisture to avoid internal

corrosion.

13. During the first few months of operation it is rec-

ommended that the bearing setscrews be checked

periodically to ensure that they are tight.

14. The rotating propeller requires particular attention

since materials in the air being handled can build

up on the blades to cause destructive vibration or

weaken the structure of the propeller by corroding

and/or eroding the blade metal. Regular inspection

and corrective action at intervals determined by the

severity of each application are essential to good

service life and safety.

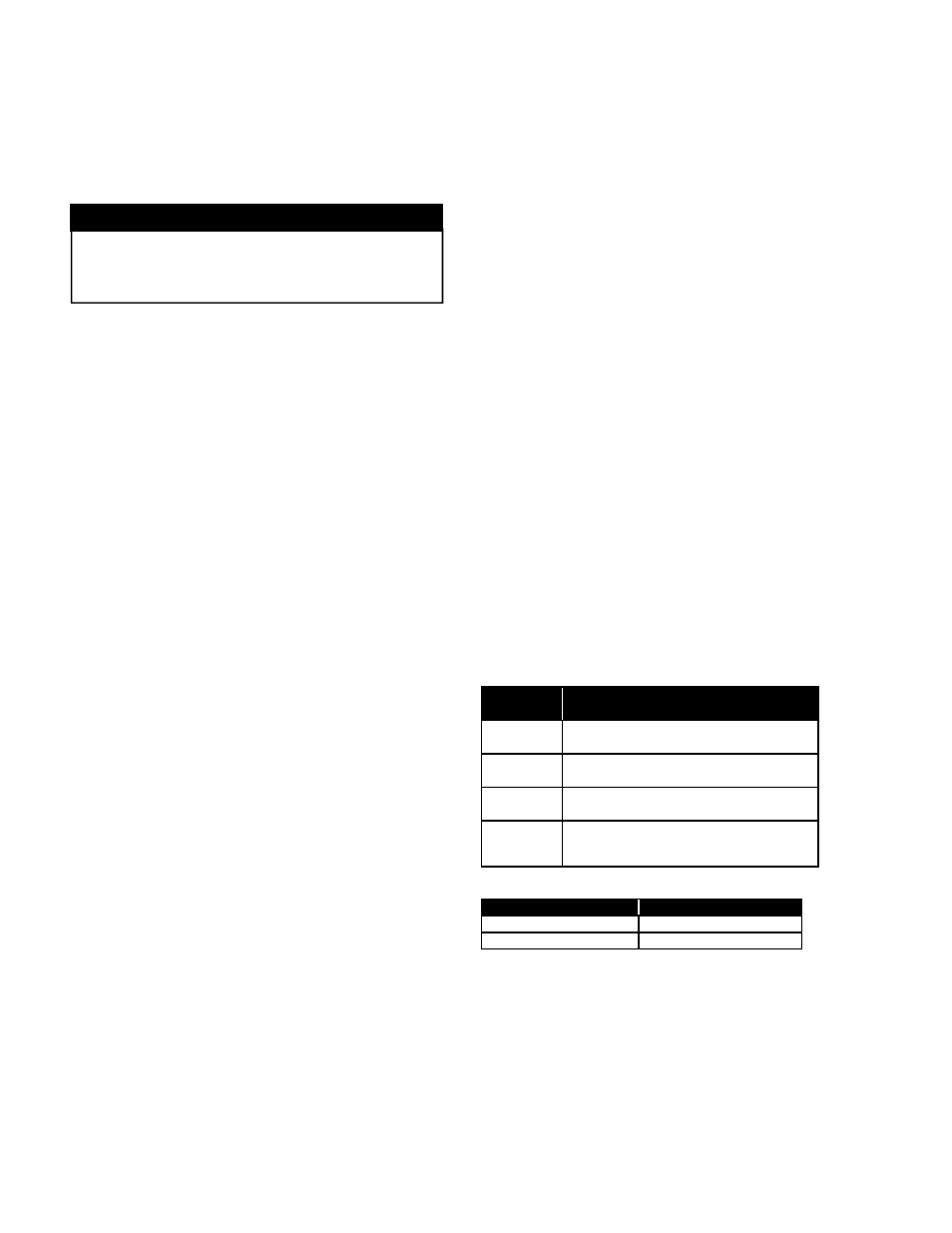

Table 1. Suggested Fan Bearing Greasing Intervals

Table 2. Grease Manufacturers

MANUFACTURER

GREASE (NLGI #2)

Shell

Gadus S2 V100 2

Exxon/Mobil

Ronex MP

INTERVAL

(MONTHS)

TYPE OF SERVICE

12 to 18

Infrequent operation or light duty in

clean atmosphere

6 to 12

8 to 16 hrs./day in clean, relatively dry

atmosphere

3 to 6

12 to 24 hrs./day, heavy duty, or if

moisture is present

1 to 3

Heavy duty in dirty, dusty locations; high

ambient temperatures; moisture laden

atmosphere; vibration