Type j - adjustable pitch wheel, Cleaning propeller and guide vanes, General maintenance – Aerovent IM-160 User Manual

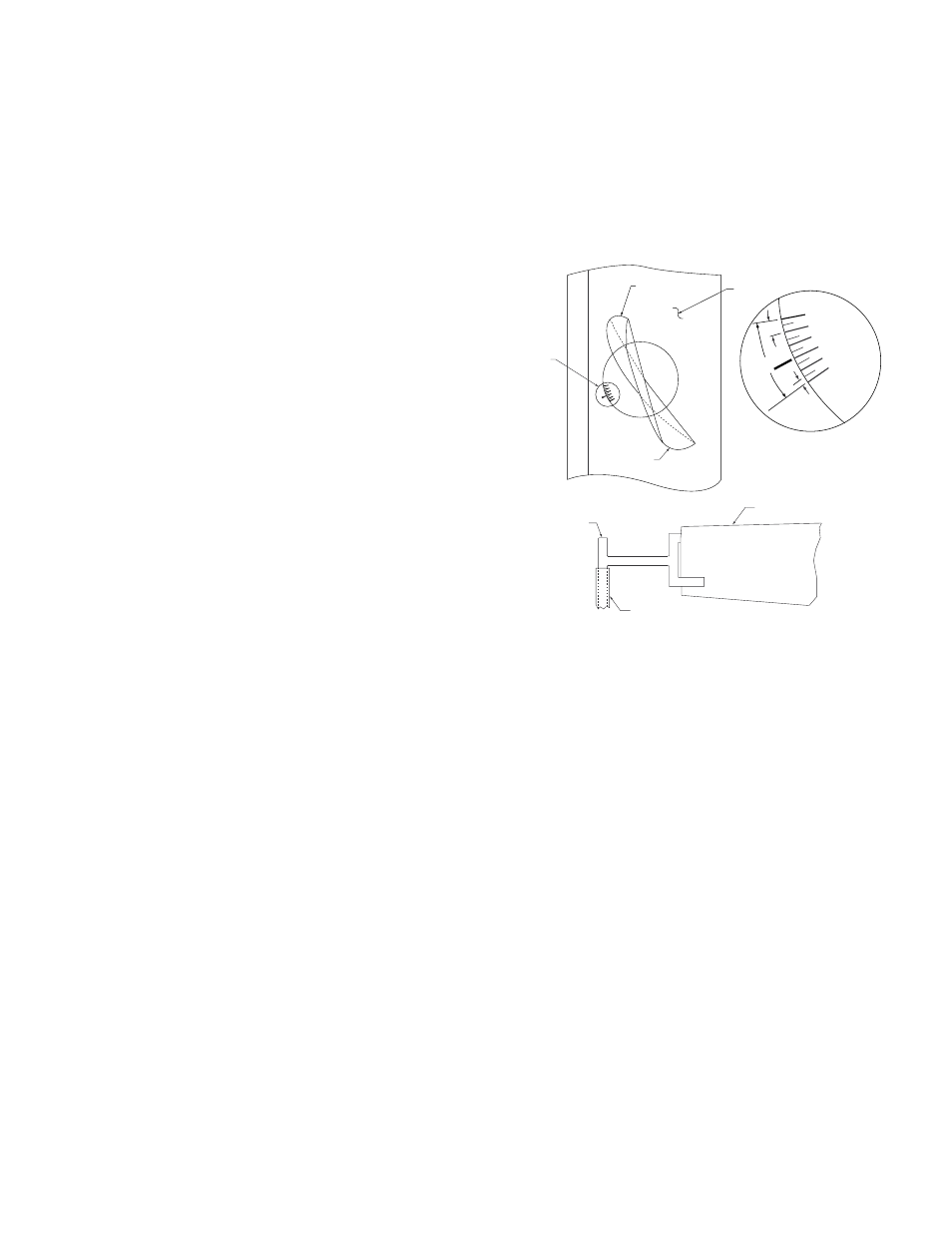

Page 3: Blade angle adjustment

3

Aerovent IM-160

Figure 1.

5

4

3

Tool AS-14093

Blade Tip

Cheater Bar

Hub

Blade

Leading Edge

Detail "X"

Blade

Trailing Edge

Detail “X”

Vernier Index Line

(Blade As Shown

Is Adjusted To 35°

)

25.0"

5.0"

2.5"

5

4

3

Blade

Hub

Type J - Adjustable Pitch Wheel

Blade Angle Adjustment

The blades are set at the factory to the blade angle

that gives the performance specified on the order.

This angle should be checked prior to start-up. The

patented wheel construction uses friction and cen-

trifugal force to hold the blades in place. No disas-

sembly of the wheel is required to change the blade

angles. If it is necessary to change the blade angle,

the following procedure should be used:

1. Work safely. Make sure that proper safety precau-

tions have been followed. Electrical power must be

locked off.

2. The adjustment can be made through the inlet on

open inlet fans. On fans with ducted inlets, open

the wheel area access door.

3. Place adjustment tool around end of blade (see

Figure 6, below). If necessary, apply “cheater bar”

around the 1

1

⁄

4

" diameter end for additional leverage.

The blades can be turned by hand on open

inlet fans. If additional leverage is needed, place

a wrench on the leading edge of the blade near

the hub. Take care not to mar the surface of the

blade.

4.

Prior to adjusting the blade angle, check the per-

formance data to insure that the motor will not

overload.

5. Turn blade to desired angle. See Figure 1. There

is an indicator mark on the hub. Align the Vernier

index line on the blade with the indicator mark on

the hub. The Vernier has the characters 3, 4, and

5 with gradation lines in between. (Note: Character

3 is 30°, 4 is 40°, 5 is 50°.) Each gradation is 2.5°.

The blade is adjustable between 25° and 50°.

6. Friction and centrifugal force will hold the blade at

the set angle. No additional adjustment is necessary.

7.

Adjust all blades to the same angle.

8. Close the wheel area access door before operating

the fan.

The propeller in an axial flow fan must be kept

reasonably clean if it is to perform properly. Fans

handling fresh air for ventilating purposes will seldom

need cleaning. Fans exhausting process air should

be cleaned as required. Dirt or chemical deposits will

usually build up evenly on a propeller and although

performance is affected, vibration is usually accept-

able until the deposits become thick enough to

break away in crust-like pieces. When this happens,

the propeller may be thrown out of balance and the

resulting vibration could be serious. Accumulations

should be removed by solvent cleaning or scraping.

If the propeller has been coated, be careful not to

cut through this protective covering.

The vaneaxial fan is constructed with a set of

guide vanes adjacent to the propeller. These should

be cleaned at the same time the propeller is cleaned.

The guide vanes are important to the performance

of the fan and should be inspected carefully. They

may accumulate dirt even under conditions where the

propeller remains clean.

Cleaning Propeller and Guide Vanes

The key to good fan maintenance is a regular and

systematic inspection of all fan parts. Severity of the

application should determine frequency of inspection.

The components requiring service are generally the

moving parts which include bearings, propeller, belts

and sheaves and motor. Included with this shipment

is a General Installation and Maintenance Manual (IM-

100) covering these items.

General Maintenance