Snorkel TB126J CE User Manual

Page 36

Chapter 7 – Prestart Inspection

32

TB126J – 0192117EE

Wire Ropes

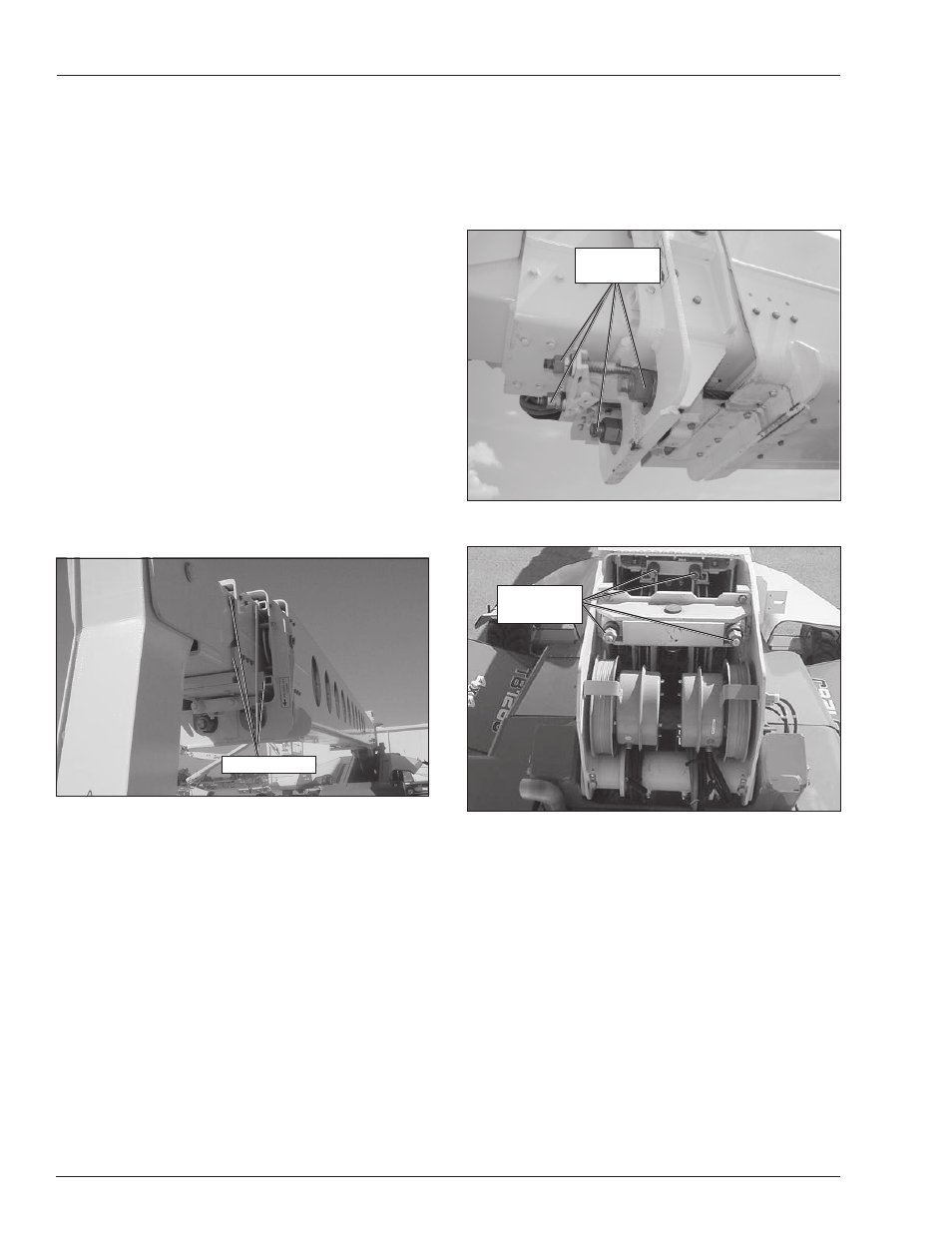

Visually inspect the wire ropes where they are connected

to the outside of the main boom. There are two wire rope

connections on the bottom of the tip end of the main

boom (refer to Figure 7.19) and inside the cover at the

base end of the main boom (refer to Figure 7.22).

Figure 7.19 – Bottom of Main Boom at Tip End

Figure 7.20 – Base End of Main Boom

Visually inspect the whiffles to ensure that they are

parallel to the edge of the boom. There are two whiffles

on the botton of the tip end of the main boom (refer to

Figure 7.21) and inside the cover at the base end of the

main boom (refer to Figure 7.22). The wire ropes run

through the whiffles.

Inspect the covers while operating the machine to en-

sure they are securely fastened and completely cover

the cylinder rod. Make sure there are no holes in the

covers.

Structures

Visually inspect all weldments and related components.

It is important to inspect the fasteners that connect the

components.

Weldments

Visually inspect all weldments for abnormal wear,

abrasion or deformation that could cause interference

between moving parts.

Inspect the welds on the structural components. Pay

particular attention to boom welds. The area to be

inspected should be clean and free of dirt and grease.

Look for visible cracks in the weld and at the weld to par-

ent material joint. A bright light may be used to provide

adequate visibility of the inspection area.

Slide Pads

The main boom has slide pads (refer to Figure 7.18)

between the main and tip boom sections.

Figure 7.18 – Slide Pads at Tip End of Boom

Use the lower controls to raise the main boom to hori-

zontal. Extend the tip boom about 30 cm (1′). Visually

inspect the slide pads (refer to Figure 7.18) to make sure

they are in place and are not obviously loose.

Inspect the surface where the pads contact the interme-

diate and tip booms. The paint must be in place with no

signs of bare metal.

The extension cylinder support bracket has slide pads

that can be inspected by looking into the base end of

the main boom.

Inspect the surface where the pads contact the main

boom. The paint must be in place with no signs of bare

metal.

Wire Rope

Connections

Slide Pads

Wire Rope

Connections