Battery maintenance – Snorkel SL30N Bi-Energy-sn13300+ User Manual

Page 6

6

Battery Maintenance

Hazard of explosive gas mixture. Keep

sparks, flame, and smoking material away

from battery(ies).

Always wear safety glasses when working

with batteries.

Battery fluid is highly corrosive. Thoroughly

rinse away any spilled fluid with clean water.

Battery Inspection and Cleaning

Check battery fluid level daily, especially if work

platform is being used in a warm, dry climate. If

required, add distilled water ONLY. Use of tap

water with high mineral content will shorten battery

life.

If battery water level is not maintained,

batteries will not fully charge, creating a low

discharge rate which will damage motor/

pump unit and void warranty.

The batteries should be inspected regularly for

signs of cracks in the cases, electrolyte leakage

and corrosion of the terminals. Inspect cables for

worn spots or breaks in the insulation and for

broken cable terminals.

Clean the batteries when there are signs of corro-

sion at the terminals or when electrolyte has

overflowed during charging. Use a baking soda

solution to clean the battery, taking care not to get

the solution inside the cells. Rinse thoroughly with

clean water. Clean battery and cable contact

surfaces to a bright metal finish whenever a cable

is removed.

Battery Charging

Note: Batteries will charge when the engine is

running. However, when Electric Mode is used

primarily, batteries will require AC charging.

Charge the batteries only in a well ventilated

area.

Do not charge the batteries when the work

platform is in an area containing sparks or

flames.

Permanent damage to the batteries will

result if the batteries are not immediately

recharged after discharging.

Never leave the charger unattended for

more than two days.

Never disconnect the cables from the

batteries when the charger is operating.

Keep the charger dry.

Charge batteries as follows:

1. Check the batteries fluid level. If the electrolyte

level is lower than 10 mm (

3

/

8

in.) above the

plates, add clean, distilled water only.

2. Verify charger voltage switch is set to the

correct voltage.

3. Connect extension cord (1.5 mm² (12 guage)

conductor minimum and 15 m (50 ft.) in length

maximum) to charger plug located through

cutout at the left side of the chassis (Figure 6).

Connect extension cord to properly grounded

outlet of proper voltage and frequency.

3. The charger turns on automatically after a short

delay.

4. The charger turns off automatically when the

batteries are fully charged.

Battery Cell Equalization

The specific gravity of the electrolyte in the battery

cells should be equalized monthly. To do this,

charge the battery as outlined in Battery Charging.

After this initial charge, check the electrolyte level

in all cells and add distilled water as necessary.

Then, charge the batteries for an additional 8

hours. During this time, the charging current will be

low (4 amps) as the cells are equalizing.

After equalization, the specific gravity of all cells

should be checked with a hydrometer. The tempera-

ture corrected specific gravity should be 1.260. If the

battery contains any cells with corrected readings

below 1.230, the battery should be replaced.

Do not check the specific gravity in a cell to which

water has just been added. If there is not enough

electrolyte in a fully charged cell to obtain a sample

for the hydrometer, add water and continue charg-

ing for 1 to 2 hours to adequately mix the water and

electrolyte.

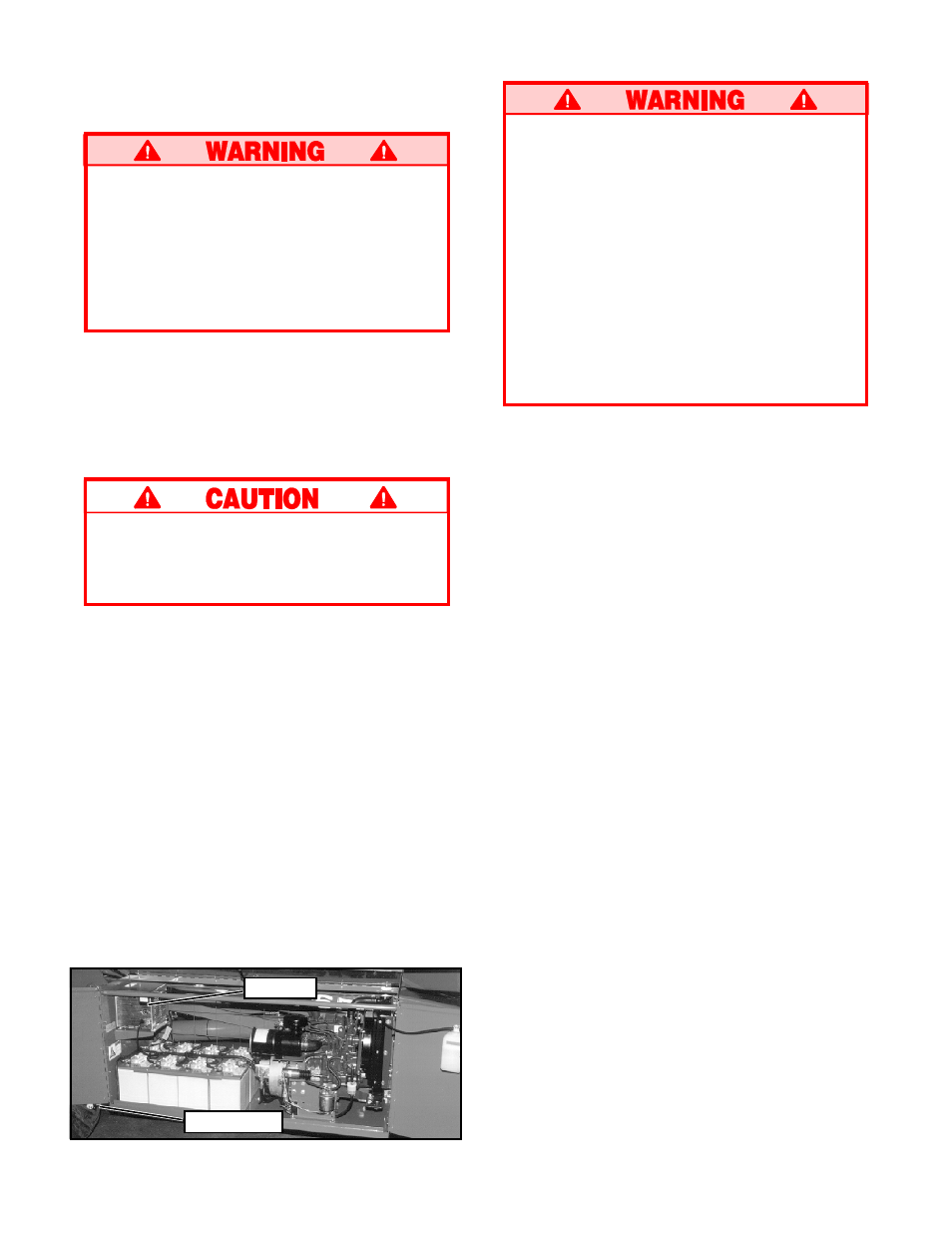

Figure 6: Power Module, Chassis Right Side

Charger Plug

Ammeter