Introduction, Pre-operation and safety inspection, System function inspection – Snorkel SL30N Bi-Energy-sn13300+ User Manual

Page 2

2

System Function Inspection

STAND CLEAR of the work platform while

performing the following checks.

Before operating the work platform survey

the work area for surface hazards such as

holes, drop-offs, bumps and debris.

Check in ALL directions, including above

the work platform, for obstructions and

electrical conductors.

Protect control console cable from possible

damage while performing checks.

1. Unhook Controller from front guardrail. Firmly

grasp Controller hanger in such a manner that

the Interlock Lever can be depressed, while

performing the following checks from the

ground.

2. Pull Controller Emergency Stop Button out to

ON position.

3. Select Electric Mode by turning Controller Key

Switch clockwise to ON. DO NOT START

ENGINE.

4. Turn Drive/Lift Switch to DRIVE position.

5. With the Speed Range Switch first in HIGH

TORQUE and then in HIGH SPEED actuate the

Interlock Lever and slowly push the Control

Handle to FORWARD then REVERSE posi-

tions to check for speed and directional control.

The farther you push or pull the Control Handle

from centre the faster the machine will travel.

6. Push Steering Switch RIGHT then LEFT to

check for steering control.

7. Rehook Controller on front guardrail.

8. Turn the Chassis Key Switch to CHASSIS,

push Chassis Lift Switch to the UP position and

elevate platform while pushing the Tilt Sensor

off of level. The platform should only elevate

about .3 m (1 ft.) and the Tilt Alarm should

sound. If the platform continues to elevate and/

or there is no alarm STOP and remove the

machine from service until it is repaired.

9. Release the Tilt Sensor and fully elevate plat-

form.

10. Visually inspect the elevating assembly, lift

cylinder, cables and hoses for damage or

erratic operation. Check for missing or loose

parts.

11. Lower the platform partially by pushing Chassis

Lift Switch to DOWN, and check operation of

the audible lowering alarm.

Introduction

This manual covers SL26/30 Narrow Work Plat-

forms with Bi-Energy power option. This manual

must be stored on the machine at all times.

Pre-Operation and Safety

Inspection

Read, understand and follow all safety rules

and operating instructions and then perform

the following steps each day before use.

1. Remove module covers and inspect for dam-

age, oil leaks or missing parts.

2. Check the level of the hydraulic oil with the

platform fully lowered. Oil should be visible in

the sight gauge. Add hydraulic oil, if necessary

(see Specifications, back cover).

3. Check that the fluid level in the batteries is

correct (see Battery Maintenance, page 6).

4. Carefully inspect the entire work platform for

damage such as cracked welds or structural

members, loose or missing parts, oil leaks,

damaged cables or hoses, loose connections

and tire damage.

5. Check that all guardrails are securely in place

with all fasteners properly torqued.

6. Place the Chassis Emergency Stop Switch to

the ON position by pulling the button out.

7. Check fuel supply.

8. Check engine oil level with dipstick.

9. While the engine is cool check the radiator

coolant level. DO NOT check coolant when the

engine or radiator is hot.

10. Verify batteries are charged (see Battery

Maintenance, page 6).

11. Check that AC extension cord has been discon-

nected from charger.

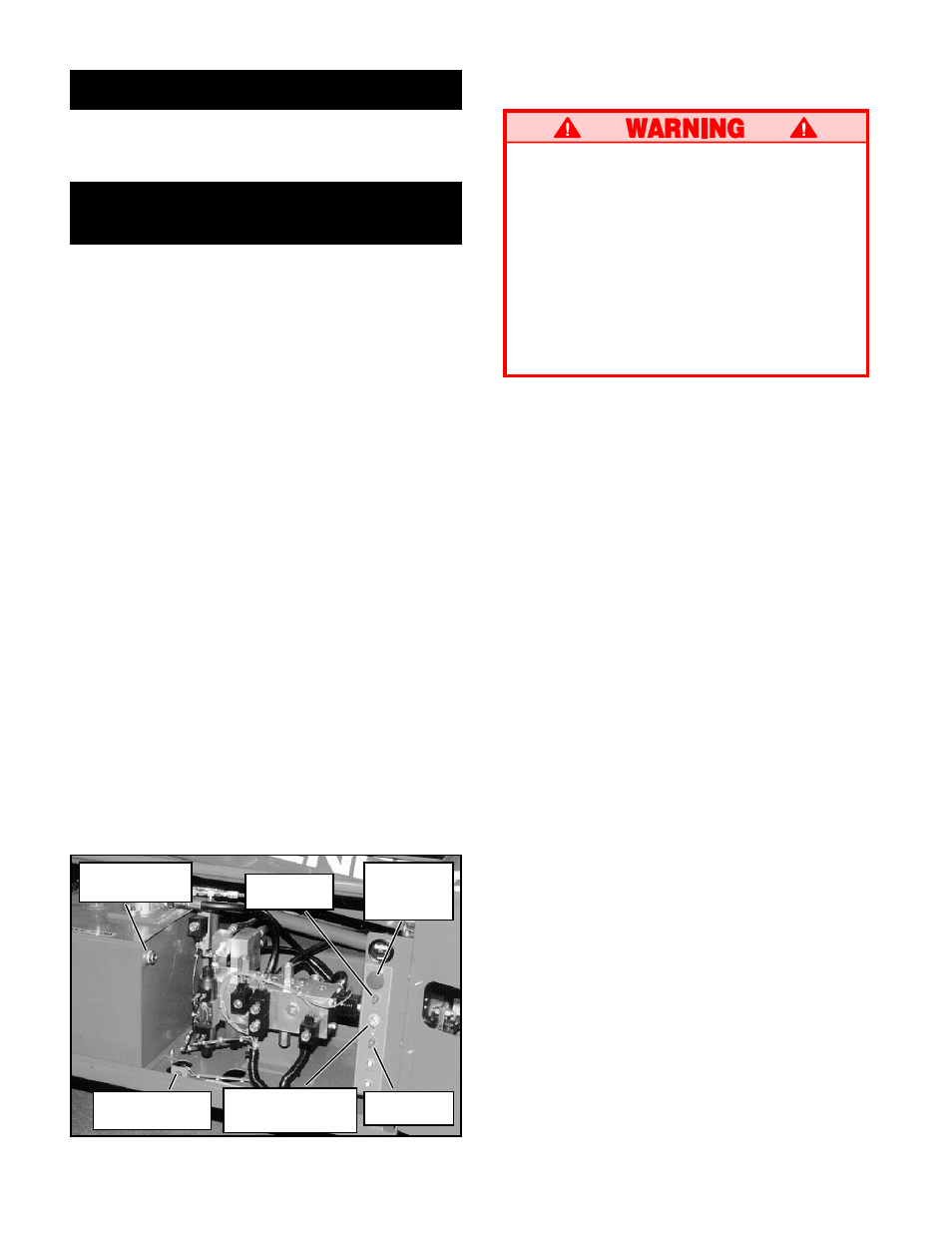

Figure 1: Control Module, Chassis Left Side

Emergency

Lowering Switch

Glow / Start

Switch

Chassis / Platform

Key Switch

Chassis

Emergency

Stop Button

Chassis Lift

Switch

Hydraulic Tank

Sight Gauge