Maintenance, Erection procedure, By crane – Snorkel SL30N Bi-Energy-sn13300+ User Manual

Page 5: By truck, Transporting work platform by forklift

5

3. Close and latch the gate.

4. Remove nuts, bolts and washers from the top

of the rear guardrail. Fold the rear guardrail

down onto the platform being careful to keep

gate latched at all times.

5. Remove nuts, bolts and washers from the top

of the side guardrails and from the slideout

deck midrail. Lift up and fold one side guardrail

in so it rests on the deck. Repeat with other

side guardrails.

Erection Procedure

1. Raise side guardrails making sure each is

pushed down to secure the guardrail in the

vertical position.

2. Install bolts, washers and nuts between the

side guardrails, tighten securely.

3. Raise rear guardrail assembly, aligning holes

and install bolts, washers and nuts. Tighten

securely.

Before entering Platform, guardrails must be

securely fastened in their proper position.

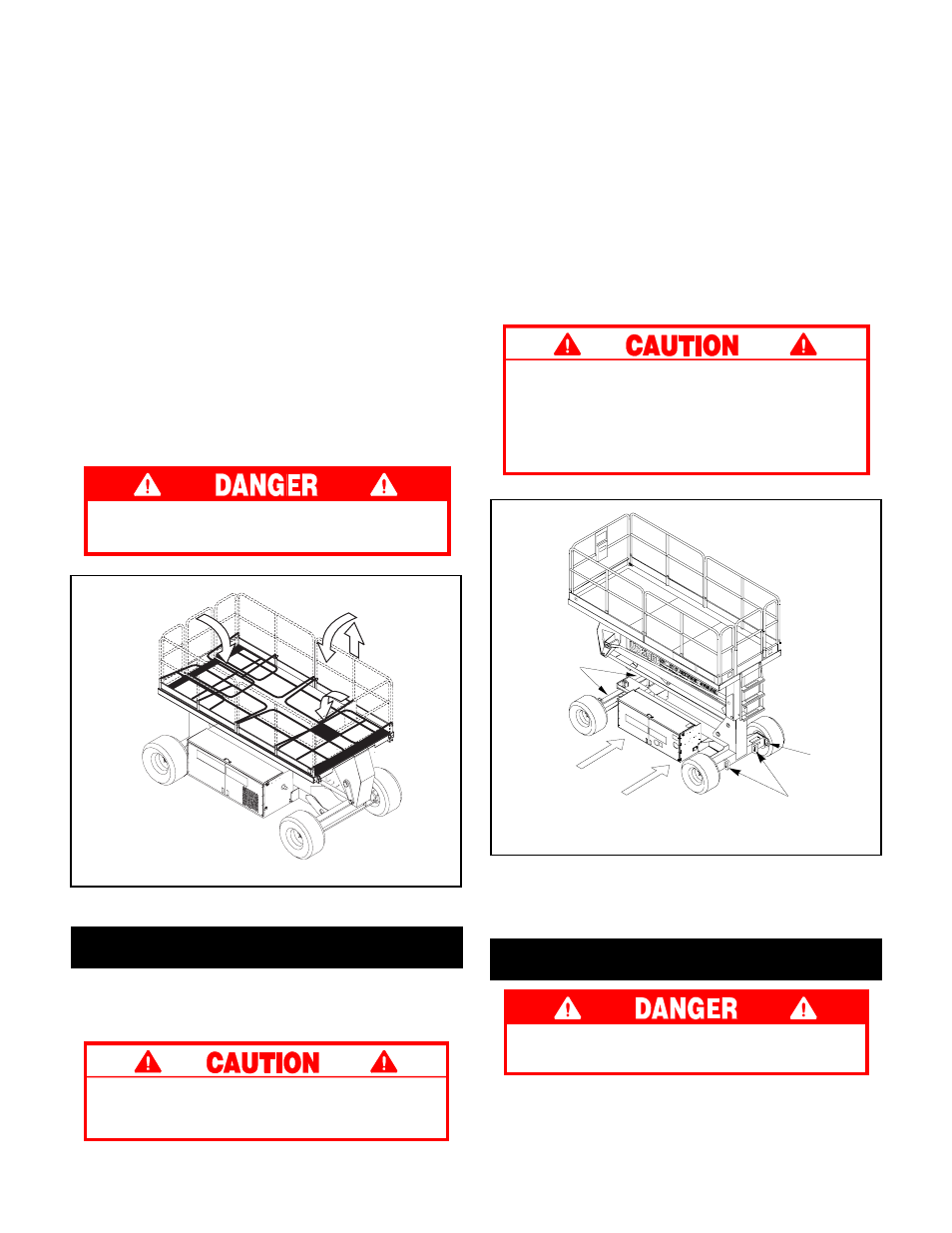

Figure 4: Fold Down Guardrails

Forklift from side of Chassis by lifting under the

Chassis Modules (Figure 5).

By Crane

Secure straps to Lifting Lugs only (Figure 5).

By Truck

1. Manoeuvre the work platform into transport

position and chock wheels.

2. Secure the work platform to the transport

vehicle with chains or straps of adequate load

capacity attached to the chassis tie down lugs

(Figure 5).

Tie down lugs are not to be used to lift work

platform.

Overtightening of chains or straps through

tie down lugs may result in damage to work

platform.

Figure 5: Transporting Work Platform

Maintenance

Never perform service on the work platform

while the platform is elevated.

Note: No normal (routine) maintenance on the

SL26/30N should require the platform to be

raised.

Transporting Work Platform

By Forklift

Note: Forklifting is for transporting only.

See specifications for weight of work platform

and be certain that forklift is of adequate

capacity to lift machine.

Front Tie

Downs/

Lifting Lugs

Forklift

Rear Lifting

Lug

(Typical)

Rear Tie

Downs