Snorkel SB126J User Manual

Page 66

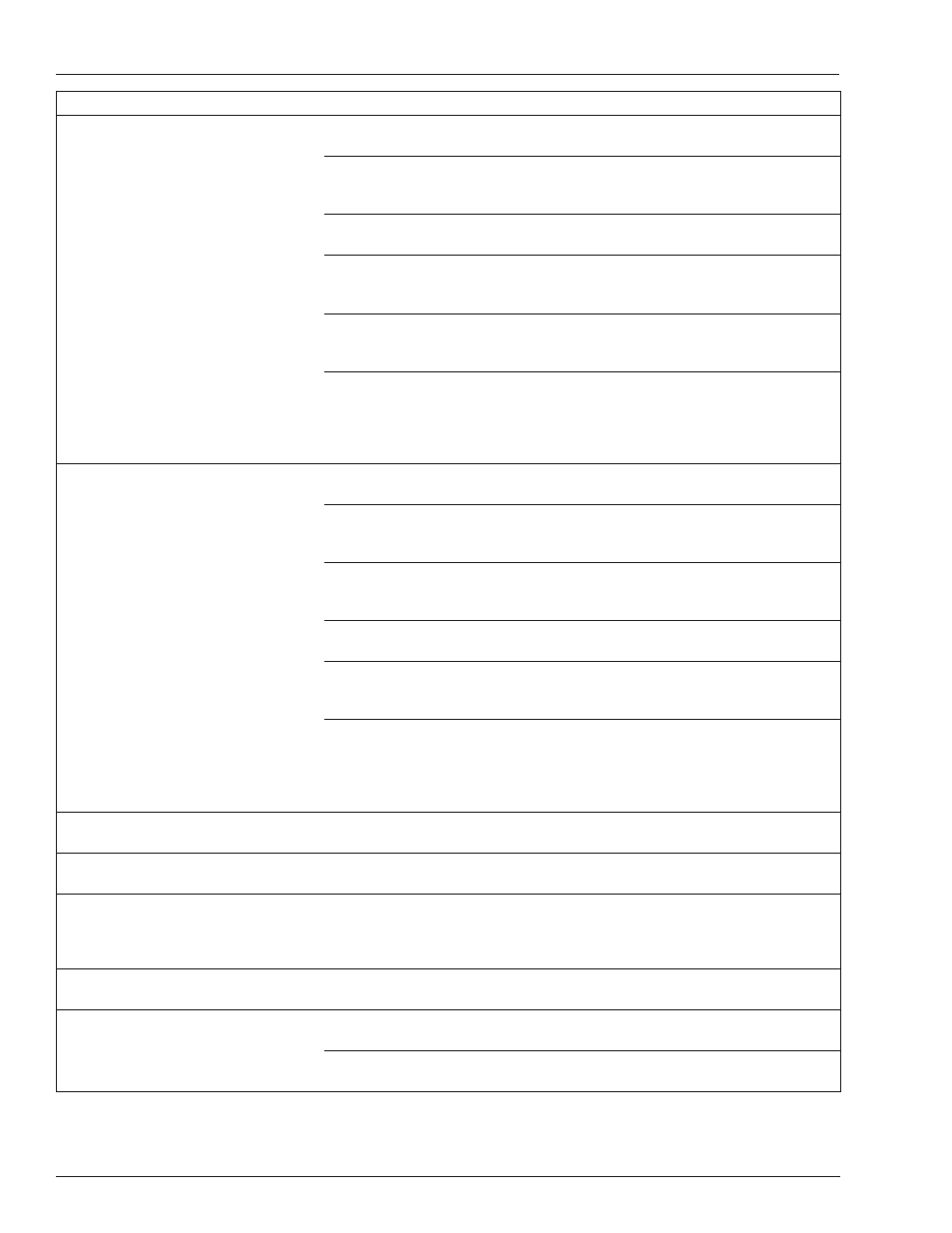

Chapter 11 – Troubleshooting

60

SB126J – 0192278

Symptom

Possible Cause

Corrective Action

Lower controls do

not work.

Battery disconnect switch turned

off.

Place switch in the on position.

Emergency stop button at lower

controls is pushed in to the off

position.

Pull the emergency stop button

outward.

Controls selector switch is in the

platform position.

Place the switch in the lower con-

trols position.

Ground operation switch not held in

the on position.

Hold the ground operation switch in

the on position while operating the

control toggle switches.

Platform overload sensor is tripped.

The horn is sounding and red over-

load light is blinking.

Remove weight from the platform

until the load is at or below rated

capacity.

Platform overload sensor is in error

mode. The horn is sounding and red

overload light is constantly on.

Remove weight from the platform

until the load is at or below rated

capacity. Cycle machine power off,

then on. If alarm, continues, system

may need recalibration.

Upper controls do not work.

Battery disconnect switch turned

off.

Place switch in the on position.

Emergency stop button at lower

and upper controls is in the off

position.

Pull the emergency stop buttons

outward.

Control selector switch at lower

controls is in the lower controls

position.

Place switch in the upper controls

position.

Platform foot switch not engaged.

Step down on platform foot switch

while operating controls.

Platform overload sensor is tripped.

The horn is sounding and red over-

load light is blinking.

Remove weight from the platform

until the load is at or below rated

capacity.

Platform overload sensor is in error

mode. The horn is sounding and red

overload light is constantly on.

Remove weight from the platform

until the load is at or below rated

capacity. Cycle machine power off,

then on. If alarm, continues, system

may need recalibration.

Boom functions do not work.

The drive/boom switch is in the drive

position.

Place the switch in the boom posi-

tion.

Boom will not extend or raise above

horizontal.

Rear axles not properly extended.

Extend the rear axles and properly

install the pin and lock.

Boom and drive functions seem

sluggish.

Hydraulic oil is cold and thick.

Use cold weather hydraulic oil as

recommended for weather condi-

tions. Warm oil before operating

the machine.

Boom jerks while it is extended.

Wire ropes are loose.

Refer the problem to a qualified

service technician.

Booms drift down.

The emergency lowering valve is

open.

Turn the emergency lowering knob

to close the valve.

Hydraulic system malfunction.

Stow the machine and do not oper-

ate until repairs are made.