Warning, Chapter 7 – prestart inspection, Caution – Snorkel SB126J User Manual

Page 31

SB126J – 0192278

25

Potential service and safety problems may be detected

by inspecting the aerial platform. This chapter includes

information on properly inspecting the aerial platform

and includes a prestart inspection check list at the end

of the chapter to ensure that no areas are overlooked.

A

Warning

The potential for an accident increases when operat-

ing an aerial platform that is damaged or malfunc-

tioning. Death or serious injury can result from such

accidents. Do not operate the aerial platform if it is

damaged or malfunctioning.

Perform a prestart inspection at the beginning of each

shift, before using the aerial platform on the job. The

inspection site must have a smooth and level surface.

Operator’s Manual

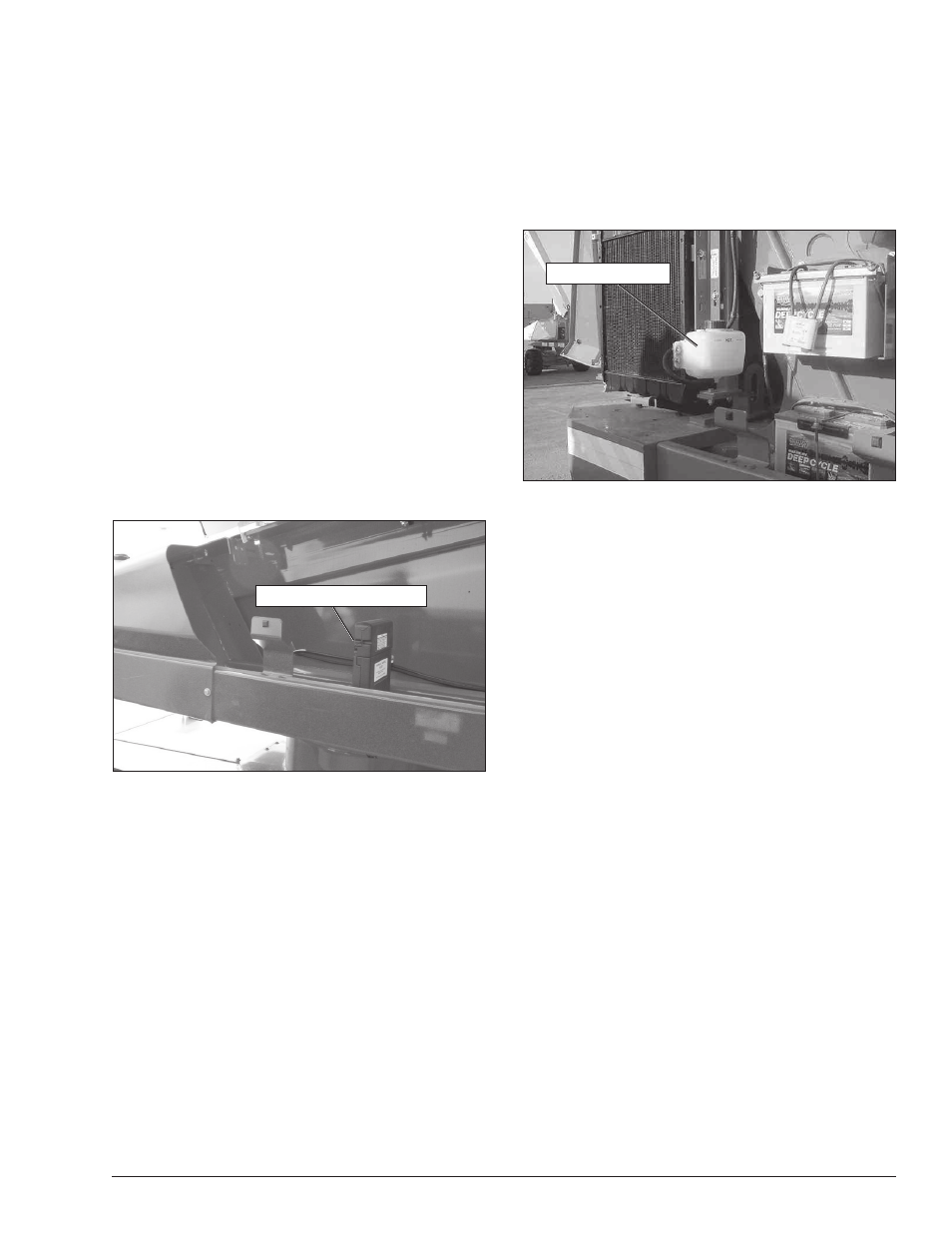

The manual holder is located behind the right rear cowl-

ing door (refer to Figure 7.1). Make certain it is securely

fastened in place.

Figure 7.1 – Operator’s Manual Holder

Check to see that the proper Operator’s Manual is in the

holder. The manual should be complete with all pages

intact and in readable condition.

Engine

Open the engine compartment doors on both ends, sides

and end of the machine and visually inspect the engine

and its components with the engine off.

Oil Level

Check the engine oil level before starting the engine

so the oil has drained to the pan. The proper oil level is

between the add and full marks on the dipstick.

The distance between the top and bottom dipstick marks

corresponds to about 1 l (1 quart US). Add oil, if neces-

sary, before starting the engine.

Chapter 7 – Prestart Inspection

Coolant

The engine is liquid cooled. The coolant reservoir is

located behind the left front cowling door (refer to Figure

7.2). When the engine is cold, there should be about 2.5

cm (1

″) of coolant in the bottom of the reservoir.

Figure 7.2 – Coolant Reservoir

A

Caution

Engine coolant escaping under pressure can cause

serious burns. Shut the engine off and let it cool

before removing the radiator cap.

Add coolant, if necessary, when the engine is cold and

not running. When running at operating temperature the

coolant should be at the hot level.

Radiator

Inspect the radiator hoses and clamps for wear, leak-

age, or damage. Make sure the hoses are not hardened,

cracked, or feel spongy. Make sure the cap is in place

and tight.

Coolant leaks are easily visible on the ground. Check

under the chassis for coolant that has leaked.

Make sure the radiator core and ventilation openings on

the cover are free of bugs, dirt, or foreign material that

might restrict airfl ow.

Fuel Tank

Check the fuel level (refer to Figure 7.3) and add fuel if

necessary. Make sure the cap is securely fastened.

Operator’s Manual Holder

Coolant Reservoir