Synergy JK OE Replacement Drive Shaft User Manual

Page 2

4.

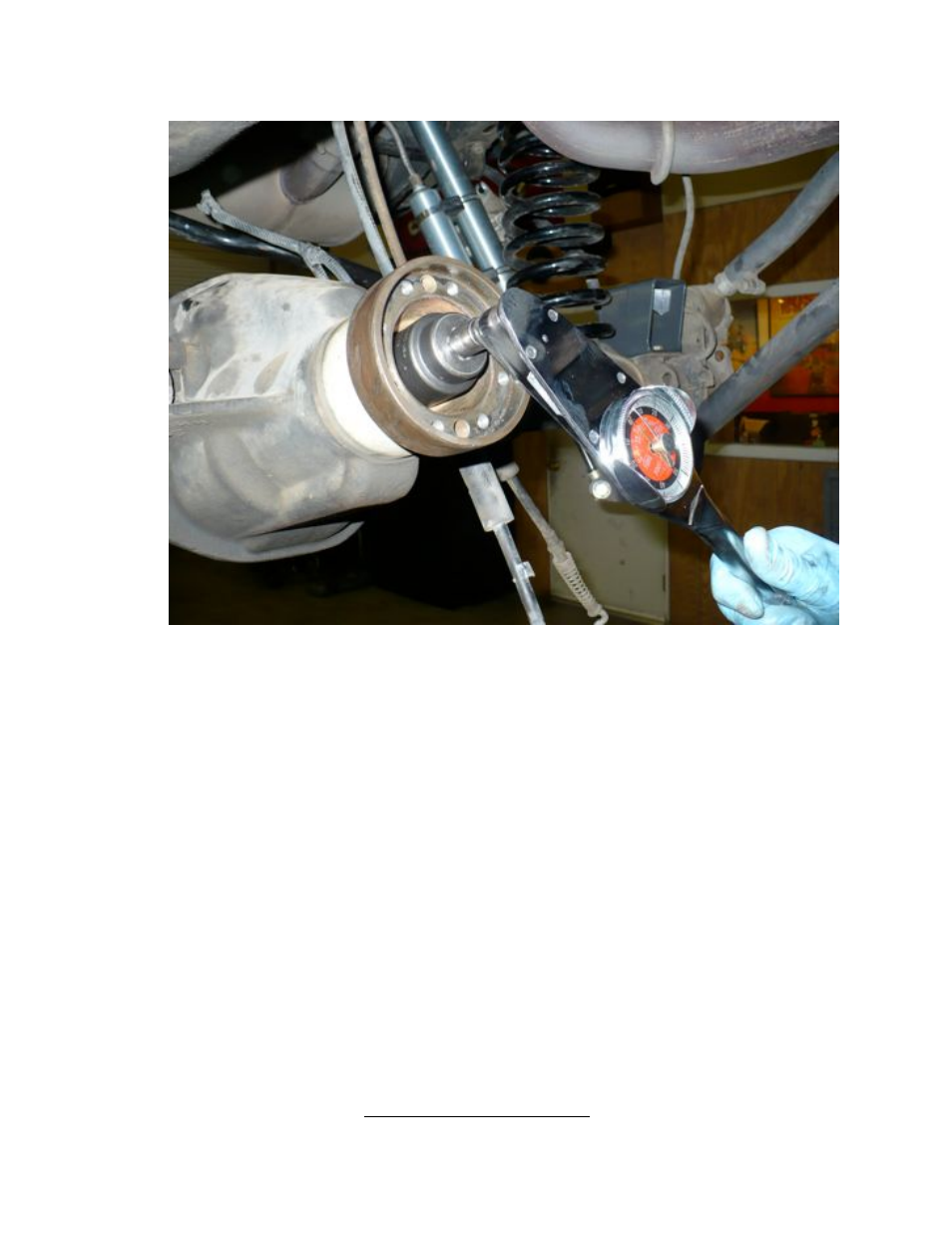

Rotate the pinion gear three or four times and record pinion torque to

rotate with an inch pound torque wrench.

5. Remove the T-case yoke nut and yoke. An air impact works well. Sometimes a

puller is needed to remove the yoke.

6. Install the new pinion yoke with a new nut. The new pinion yoke do not use the dust

shield like the original yoke did. You can remove the dust shields from the old yoke

and install on to the new yokes if you want. The new front and rear pinion yokes are

the same. If you are not installing a new pinion nut, use red loctite on the old pinion

nut threads.

7. Tighten the pinion nut to 160 ft-lbs and measure the pinion torque to rotate. The new

pinion rotating torque needs to be 5 in-lbs more that it originally was.

8. If pinion rotating torque is low, tighten the pinion nut in 5 ft-lb increments until the

desired pinion rotating torque is achieved.

CAUTION: If maximum tightening torque of 200 ft. lbs. is reached before torque to

rotate is achieved, the collapsible spacer may have been damaged. Never loosen

pinion gear nut to decrease pinion gear bearing rotating torque and never exceed

specified preload torque. Failure to follow these instruction may result in damage.

TRANSFER CASE YOKES