3 - safety, 4 - technical specifications – Lukas AHP2-1 User Manual

Page 15

15

COD. 193553057 - v.1 - UPD 080703

3 - SAFETY

Observe all the following safety rules. They are of the maximum importance for your own safety and the safety of

others. In addition to the indications in this chapter, observe also the prescriptions in all other sections of the manual.

DO NOT TAMPER WITH THE PROTECTIONS AND SAFETY DEVICES AND DO NOT MODIFY THE PUMP IN ANY

WAY TO AVOID CREATING POTENTIALLY HAZARDOUS SITUATIONS FOR WHICH THE OPERATOR OR THE

SERVICE TECHNICIAN IS UNPREPARED.

REMOVING OR TAMPERING WITH ANY OF THE SAFETY DEVICES ON THE PUMP AUTOMATICALLY

INVALIDATES THE WARRANTY AND ABSOLVES THE MANUFACTURER FROM ALL LIABILITY.

l The pump and the machine on which the pump is installed must be used exclusively by people over 18 years of

age who have read this manual and have a thorough knowledge of the machine and the pump.

l The pump may be used by people over the age of 16 provided they are supervised by an adult.

l The work area must be kept clear of obstructions so that the pump can be operated in safe conditions.

Pay attention to falling objects which could strike the pump treadle and set the pump into operation.

l The work area must be kept clean and the floor must bear no traces of oil, grease or any other slippery or corrosive

substances.

l Keep the pump well clear of heat sources, naked flames and sparks. Maximum operating temperature of the pump is 50° C.

l The pump must be set into operation exclusively using feet. It is potentially dangerous to operate the pump with

any other part of the body.

l Work clothes must be close fitting and buttoned up. Wear the protective clothing stipulated in the place where the

pump is installed.

l Do not attempt to operate the pump by standing on the treadle, use only light foot pressure to operate the pump

mechanism.

l Do not disconnect the air supply hose or the hydraulic oil hose until you are sure that the circuits are not

pressurized.

l When connecting the pump follow the prescriptions in chapter 5 Installation and start-up and always use certified

hoses and couplings.

l If the pump develops a fault, do not attempt to repair it unassisted. Disconnect the compressed air supply, switch

off the machine to which the pump is connected and call a maintenance technician.

l Do not arbitrarily move the pump to different locations. The pump must be used in the position designated by the

manufacturer of the machine to which it is connected.

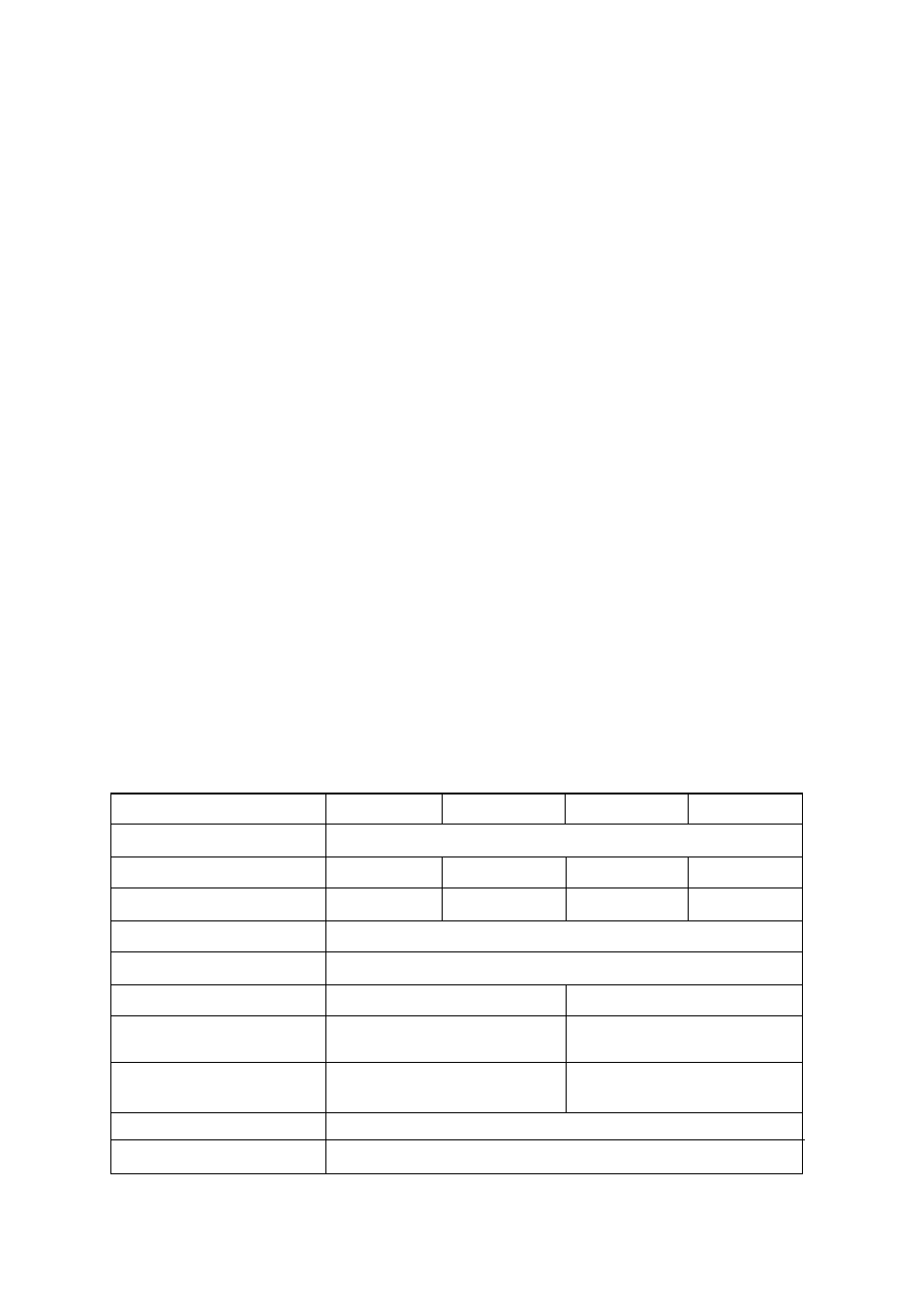

4 - TECHNICAL SPECIFICATIONS

() With 7 bar compressed air supply pressure

(*) Dif

ferent connection types

are available on request

RECOMMENDED OIL TYPES

RECOMMENDED OIL TYPES

RECOMMENDED OIL TYPES

RECOMMENDED OIL TYPES

RECOMMENDED OIL TYPES

MOBIL DTE 11 - SHELL TELLUS OIL T 15 - CASTROL HYSPIN AWH15 - or equivalent

Model

AHP 2-1E-502

AHP 2-1E-702

AHP 2-1E-505

AHP 2-1E-705

Air inlet pressure (bar)

2,8 ÷ 10

Maximum working pressure (bar)

500

700

500

700

Maximum rated flow (l/min)

1,4

0,8

1,4

0,8

Air connection (standard*)

1/4" G

Oil connection (standard*)

3/8" NPTF

Max. weight without oil (kg)

4,65

9

Reservoir capacity / usable capacity

in horizontal position (l)

2,4 / 2,1

5 / 4,5

Reservoir capacity / usable capacity

in vertical position (l)

2,2 / 1,5

3,5 / 2

Dimensions (mm)

Pump dimensions are shown on page 2, figs. 1 & 2

Noise level

75 dB(A) / 1m