Troubleshooting 11, 3 repairs – Lukas LS 330 Fi User Manual

Page 21

21

10.3 Repairs

Since repairs to the electrically insulated rescue tools must always be concluded by testing

and confirmation of the minimum electrical arcing resistance, repairs may only be carried out

by authorised specialised dealers or by LUKAS directly.

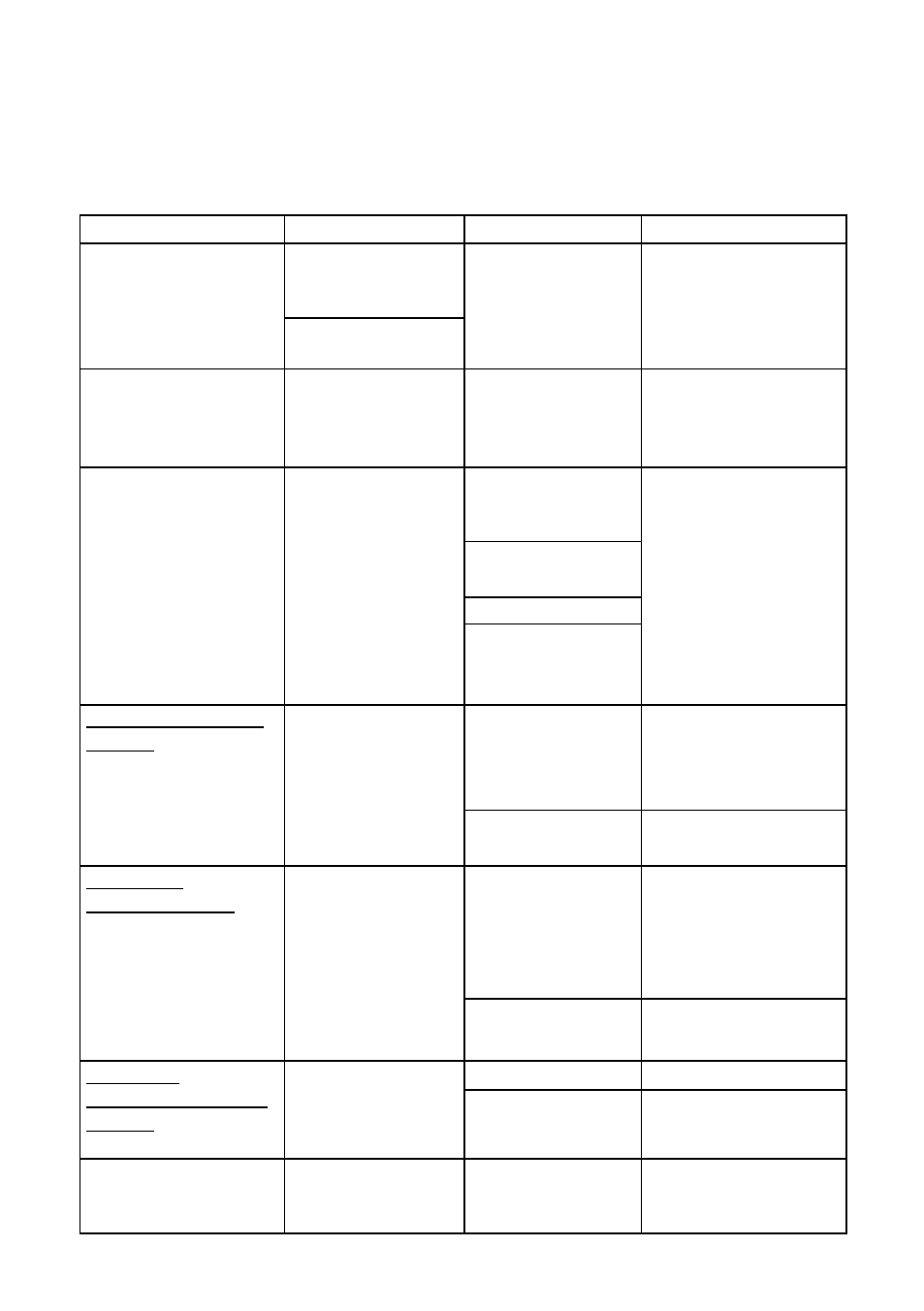

Troubleshooting

11.

Trouble

Control

Cause

Solution

Blade arms move

slowly or jerkily when

activated

Are the hoses

connected

properly?

Air in the hydraulic

system

Deaerate pump

system

Does the pump

unit work?

Device doesn’t

perform at its given

power

Check the

hydraulic fluid level

in the supplying

pump

Insufficient

hydraulic fluid in

the pump

Top up hydraulic fluid,

deaerate

Following release,

the star grip doesn’t

return to the central

position

Cover damaged

or star grip hard to

move?

Damage to the

torsion spring for

reset

Repair by an

authorised dealer, by

personnel specially

trained by LUKAS, or

by LUKAS itself

Soiled valve or

star grip

Defective valve

Other mechanical

damage (e. g. star

grip)

with mono-coupling-

system: Hoses

cannot be coupled

Pressure too high

(e.g. caused by

too-high ambient

temperature)

Set hydraulic pump

to pressureless

circulation

Coupling defective Coupling needs to be

replaced immediately

with mono-

coupling-system:

It is frequently not

possible to couple

hose assemblies

Control the

degree of viscosity

and application

temperature of

the used hydraulic

fluid

Hydraulic fluid

not adapted to

the application

situation

Hydraulic fluid

must be replaced

(see chapter

“Recommended

Hydraulic fluids”)

Coupling defective Coupling needs to be

replaced immediately

with quick-

disconnect-coupling-

system: Hoses

cannot be coupled

Is the pump

working?

Pressurized

Relieve pump

Coupling defective Coupling needs to be

replaced immediately

Hydraulic fluid leak

on the hoses or the

fixing-ins

Are the hoses

defective?

Leak, possible

damage

Replace hoses