Lull 1044C-54 Series II Operation Manual User Manual

Page 28

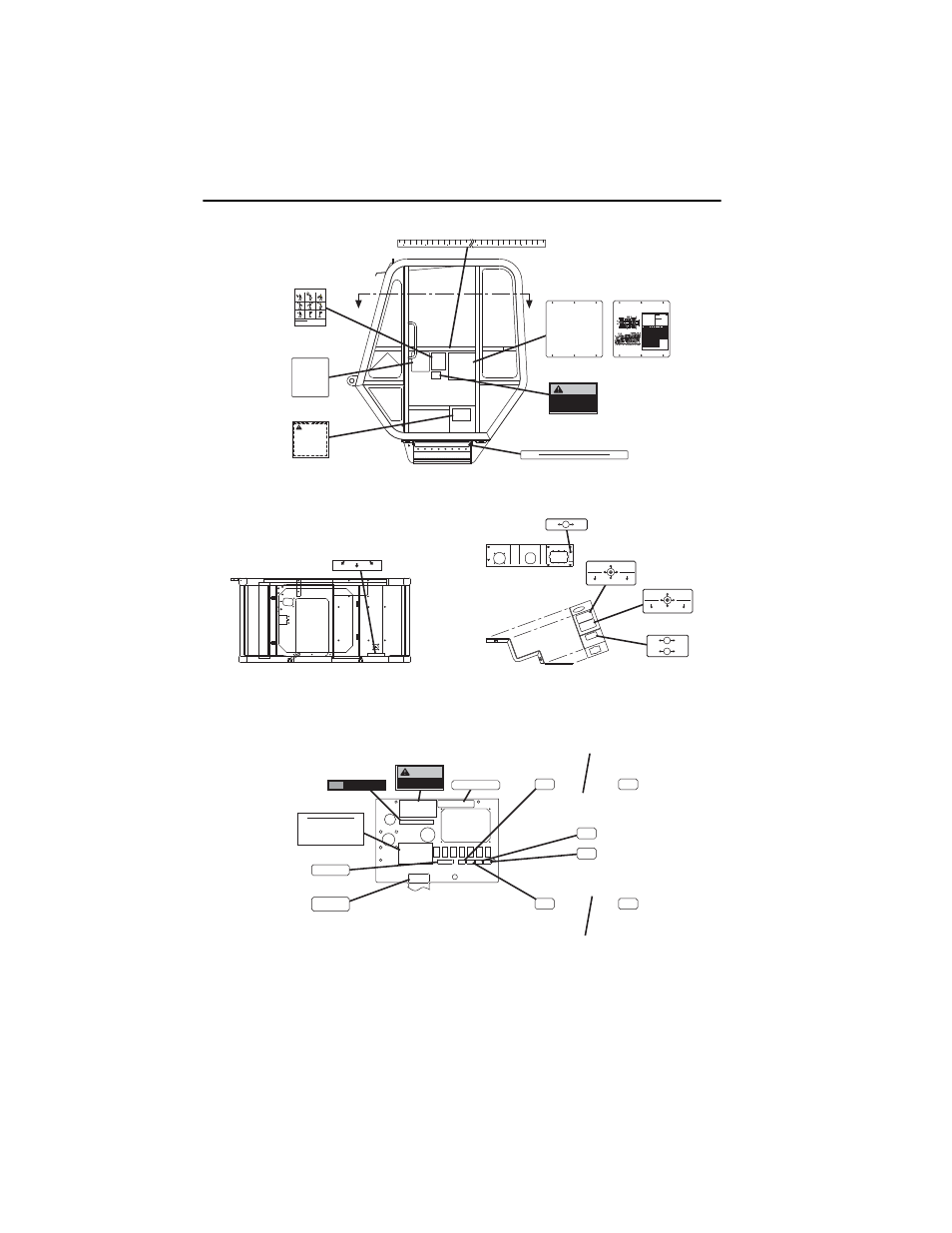

Section 2 - Pre-Operation and Inspection

2-4

31200608

OV0100

DO NOT OPERATE MACHINE WHEN

LOW BRAKE PRESSURE LIGHT IS ON.

10124906

10167809

Carry load in low position.

CAUTION

10167810

Consult operators manual before

using drive lockout override switch.

WARNING

10167808

Stabilizer System Operation

With boom below 20°, rear axle oscillates freely.

With boom between 20° and 40°:

Transmission is limited to first or second gear.

Rear axle is in restricted oscillation mode.

Frame tilt function operates at reduced speed at any boom

angle above 20°.

With boom above 40°:

Transmission is locked out and rear axle oscillation is locked to frame.

Frame tilt function still operates at reduced speed.

With boom above 40° and foot switch depressed:

Transmission is limited to first gear.

Rear axle is in very restricted oscillation mode.

Fully depressing brake pedal locks rear axle at any boom angle.

10135193

PULL TO APPLY

PUSH TO RELEASE

PARKING BRAKE

10135193

10135082

TRANSMISSION

DECLUTCH

HAZARD

LIGHTS

10138460

(IF EQUIPPED)

BEACON

LIGHT

10139648

(IF EQUIPPED)

WORK

LIGHTS

10138409

(IF EQUIPPED)

ROOF

WIPER

10139610

(IF EQUIPPED)

10138377

(IF EQUIPPED)

STROBE

LIGHT

WINDSHIELD

WIPER

10138410

(IF EQUIPPED)

ROUND STEER

FRONT WHEEL STEER

OBLIQUE STEER

10112750

10130487

FRAME

TILT

LEFT

FRAME

TILT

RIGHT

10135091

FORK TILT DOWN

FORK TILT UP

TRANSFER

IN

AUXILIARY

PRESS AND HOLD BUTTON FOR AUXILIARY FUNCTION

TRANSFER

OUT

AUXILIARY

10135090

BOOM DOWN

BOOM UP

BOOM IN

AUXILIARY

PRESS AND HOLD BUTTON FOR AUXILIARY FUNCTION

BOOM OUT

AUXILIARY

10138929

RAISE

LOWER

RIGHT

RAISE

LOWER

LEFT

OUTRIGGERS

10438304

cm

10

20

30

FT

1

0

110

90

FT

3

120

FT

4

100

PRESSURE TEST PORTS

PUMP 1

PUMP 2

LOCK (G1)

REAR OSC.

REAR OSC.

LOCK (G2)

BRAKES

STEERING

PILOT

ACCUM.

10339962

LUBRICATION SCHEDULE.

11. TIRES MUST BE CALCIUM CHLORIDE FILLED! REFER TO

FIND OUT FORK CAPACITY BEFORE USING MACHINE.

10. NEVER LIFT LOADS HEAVIER THAN THE CAPACITY OF THE FORKS.

9. KEEP THE WORK AREA CLEAN OF DEBRIS.

AND IN PLACE.

8. OPERATE ONLY WITH GUARDS AND SAFETY EQUIPMENT FUNCTIONING

MANUFACTURER'S PRIOR WRITTEN APPROVAL.

7. DO NOT MODIFY OR ALTER THIS MACHINE WITHOUT THE

OR MOVING THE MACHINE.

6. EVALUATE GROUND-BEARING CONDITIONS BEFORE MAKING LIFTS

FROM THE CYLINDERS.

THROUGH FULL STROKE IN EACH DIRECTION TO ELIMINATE AIR

TILT-FRAME CYLINDER AND FORK-CARRIAGE TILT CYLINDER

5. TWICE DAILY, WITH THE FORKS NEAR GROUND ELEVATION, CYCLE

MANUAL AND THE LUBRICATION SCHEDULE.

4. SERVICE THE MACHINE AS RECOMMENDED IN THE OPERATOR'S

THIS MACHINE AS A WORK PLATFORM.

3. THIS MACHINE IS NOT EQUIPPED TO LIFT PERSONNEL. NEVER USE

FORKS ABOVE EYE LEVEL MAY CAUSE THE MACHINE TO TIP OVER.

KEPT AT OR BELOW EYE LEVEL POSITION. TRAVELING WITH THE

2. WHEN TRAVELING WITH OR WITHOUT LOADS, THE FORKS MUST BE

KEEP THE OPERATOR'S MANUAL WITH THE MACHINE.

THOROUGHLY FAMILIAR WITH THE OPERATOR'S MANUAL! ALWAYS

1. DO NOT OPERAE THIS MACHINE UNTIL YOU HAVE READ AND ARE

NOTICE

10220963

10220963

STOP

RAISE LOAD

LOWER LOAD

TILT FORKS RIGHT

TILT FORKS LEFT

TILT FORKS UP

TILT FORKS DOWN

MOVE LOAD BACKWARD

MOVE LOAD FORWARD

FORKLIFT SIGNALS

INSTRUCTIONS TO SIGNALMAN

1. ONLY ONE PERSON TO BE SIGNALMAN.

2. MAKE SURE THE OPERATOR CAN SEE YOU AND IS ABLE TO ACKNOWLEDGE THE SIGNAL GIVEN.

3. SIGNALMAN MUST WATCH THE LOAD, THE OPERATOR IS WATCHING YOU.

4. NEVER RAISE OR LOWER THE LOAD OVER THE OTHER WORKMEN. WARN THEM TO KEEP OUT OF THE WAY.

5. WATCH FOR OVERHEAD LINES OR OTHER OBSTRUCTIONS.

10239617

10239617

1. DO NOT OPERATE THIS MACHINE UNTIL YOU HAVE READ AND ARE

THOROUGHLY FAMILIAR WITH THE OPERATOR'S MANUAL! ALWAYS

KEEP THE OPERATOR'S MANUAL WITH THE MACHINE.

2. WHEN TRAVELING, FORKS MUST BE AT OR BELOW EYE LEVEL POSITION.

NEVER TRAVEL WITH BOOM RAISED. FAILURE TO LOWER BOOM BEFORE

TRAVELING COULD CAUSE MACHINE TO TIP AND RESULT IN SERIOUS INJURY

OR DEATH.

3. ALWAYS LIFT & CARRY LOADS WITHIN MANUFACTURER'S RECOMMENDED

CAPACITY. REFER TO LOAD CHART ON RIGHT SIDE OF OPERATOR'S

4. DO NOT USE THE MACHINE IF MALFUNCTIONING-REPAIR FIRST.

5. FAULTY MAINTENANCE, CARELESSNESS, LACK OF OPERATOR TRAINING,

IMPROPER OPERATING PRACTICES, ETC. WILL AFFECT THE SAFETY AND

CAPACITY OF THIS MACHINE.

6. ALWAYS LEVEL MACHINE BEFORE LIFTING A LOAD. IF LEVEL INDICATOR IS

DAMAGED OR MISSING, REPLACE BEFORE USING MACHINE.

7. DO NOT USED FRAME TILT TO POSITION LOADS-LOWER LOAD TO A SAFE

HEIGHT, REPOSITION MACHINE, LEVEL MACHINE AND RELIFT TO NEW

POSITION.

8. WATCH FOR OVERHEAD OBSTRUCTIONS BEFORE AND WHILE MAKING A LIFT,

ESPECIALLY ELECTRICAL WIRES. SERIOUS INJURY OR DEATH CAN RESULT

FROM CONTACT WITH ELECTRICAL WIRES.

COMPARTMENT.

CAUTION

10220964

10220964

10139033

CAUTION

OUTRIGGERS PROVIDE A SUBSTANTIAL

INCREASE IN STABILITY

IF BOOM COAPACITIES ARE EXCEEDED WITH

OUTRIGGERS DOWN, STRUCTURAL DAMAGE

MAT CCUR BEFORE MACHINE INSTABILITY.

CONSULT LOAD CHART FOR RATED

CAPACITIES. DO NOT EXCEED RATED

LIFT CAPACITIES.

1001103932

LUBRICATE BOOM WEAR PADS AND SLIDE AREAS MONTHLY WITH

EP LITHIUM-BASED GREASE OR DRY-FILM LUBRICANT.

P/N 1706502 (A)

12

8

7

9

6

20

12

19

2

22

1

13

3

23

5

4

23

19

8

13

21

17

25

17

24

21

18

24

11

16

17

22

16

10

24

15

14

SERVICE/LUBRICATION SCHEDULE

MODEL 1044C-54 SERIES II

20

20

SEE OTHER SIDE OF THIS CARD FOR ADDITIONAL INFORMATION

SYSTEM CAPACITIES AND PRESSURES

HYDRAULIC RESERVOIR

47 GALS

FUEL TANK

36 GALS

COOLING SYSTEM

18 QTS

ENGINE CRANKCASE DEERE 4 CYL.

14 QTS

TRANSMISSION DRAIN/REFILL (APPROX.)

19 QTS

ACCUMULATOR (NITROGEN PRECHARGE)

TIRES 14.00 × 24

PER TIRE

400425 PSI

WET DISK BRAKES

HYDRAULIC SYSTEM & RESERVOIR

65 GALS

PRESSURE

65 PSI

HYDRO-FILL TIRES SHOULD BE FILLED TO

APPROXIMATELY 75% FULL (55 GALLONS/596LB)

OF CALCIUM CHLORIDE TIRE FILL.

FRONT AXLE

DIFFERENTIAL

9.5 QTS

PLANETARY HUB (EACH)

54 OZ

REAR AXLE

DIFFERENTIAL

10.5 QTS

PLANETARY HUB (EACH)

40.5 OZ

APPROXIMATED WEIGHTS:

14.00 x 24 12 PLY SGG RB G2 BIAS BELTED

HYDRO-FILLED

925 LBS

FOAM-FILLED

1050 LBS

14.00 x 24 GLA2 STEEL BELTED RADIAL

HYDRO-FILLED

1000 LBS

FOAM-FILLED

1125 LBS

* =

C =

CF =

R =

CLN =

SHORTEN SERVICE INTERVALS

ACCORDINGLY WHEN OPERATING

UNDER DUSTY OR SEVERE

CONDITIONS.

14

BOOM PIVOT

15

HOIST PIVOTS

16

TILT CYLINDER PIVOTS

INSPECT ALL FLUID SYSTEMS AND

CHANGE FLUID WHEN FLUID SHOWS

TRACES OF CONTAMINATION

OR HIGH TEMPERATURES,

EVIDENCED BY STRONG ODOR,

DISCOLORATION, OR SEPARATION

17

QUICK ATTACH PIVOT

18

OSCILLATION PIVOTS

19

FRAME TILT CYLINDER

20

REAR AXLE LOCK CYLINDER

21

22

23

24

25

DRIVE SHAFT SLIP YOKES

TRANSFER ROLLERS

1

ENGINE OIL

SEE ENGINE MANUAL

CF

*CF

C

2

ENGINE OIL FILTER

R

*R

3

FUEL FILTER(S)/WATER SEP.

R

C

4

TRANSMISSION FLUID

CF

*CF

C

5

TRANSMISSION FILTER

R

*R

6

HYD. RESERVOIR FLUID

CF

C

7

HYD. RETURN FILTER

R

*R

C

8

HYD. PRESSURE FILTER

R

*R

C

9

HYD. TANK BREATHER

R

10

AIR CLEANER

R

C

11

ENGINE COOLANT

CF

C

12

AXLE DIFFERENTIAL

CF

C

*CF

13

PLANETARY HUBS

CF

C

*CF

2 GREASE FITTINGS

LUBE

4 GREASE FITTINGS

LUBE

6 GREASE FITTINGS

LUBE

1 GREASE FITTINGS

LUBE

4 GREASE FITTINGS

LUBE

2 GREASE FITTINGS

LUBE

2 GREASE FITTINGS

LUBE

4 GREASE FITTINGS

LUBE

FIRST HOURS OF OPERATION

CHECK, SERVICE AS

NECESSARY

CHANGE FLUID

REPLACE

CLEAN CAREFULLY

SEE PARTS BOOK

SEE PARTS BOOK

SEE SERVICE MANUAL

SEE PARTS BOOK

SEE PARTS BOOK

SEE PARTS BOOK

SEE OTHER SIDE OF CARD

LUBE

LUBE

OUTRIGGERS

9 GREASE FITTINGS

CHAIN GUIDES

LUBE

5 GREASE FITTINGS

SEE ENGINE MANUAL

SEE PARTS BOOK

SEE PARTS BOOK

3 GREASE FITTINGS

SEE SERVICE MANUAL

HOURS OF OPERATION

*R

R

SEE PARTS BOOK

HYD. CARTRIDGE FILTER

#

DESCRIPTION

DAILY WEEKLY 50

100 250 500 1000 2000

REMARKS

SEE OTHER SIDE OF CARD

VIEW C-C

C

VIEW OF DASH PANEL

C

VIEW OF

JOYSTICK PANEL

CAPACITY

CHARTS