J.p.instruments, Fuel flow installation manual – J.P. Instruments EDM 760 Fuel Flow Installation Manual User Manual

Page 10

J.P.Instruments

Fuel Flow Installation Manual

Report # 760

for EDM-760 temperature indicating system with Fuel Flow Option

Appendix - A

Page Page 10 of 14 Rev NC :

Date 07/20/99

Mounting Procedure:

1. Find a convenient location within 8" of a hose support or fitting and away from any hot exhaust

pipes to suspend the Fuel Flow Transducer. The hose support or fitting may be on the input or

output line of the Flow Transducer.

2. Remove the fuel hose which goes from the Fuel Pump to the Carburetor (or Fuel Servo).

2. Purchase two new hoses, one from the fuel pump (or the Fuel Filter) to the Fuel Flow

Transducer and the other from the Fuel Flow Transducer to the carburetor (or fuel servo).

There must be flexible hose in and out of the Transducer. The hoses must meet TSO-C53a

Type C or D FAA specification. The new hoses must be the same size as

the current hose in the aircraft. A source of fittings and fabricated hoses is:

Sacramento Sky Ranch Inc.

(916) 421-7672 Fax: (916) 421-5719

Herber Aircraft

1401 E. Franklin Ave.

El Segundo, CA 90245 (310) 322-9575

4.

Mount the Fuel Flow Transducer in the fuel line. The FXT-201 Transducer is marked "Model

201" on the top of the transducer. The Flow Transducer must be wrapped with Fire

Sleeving. Place a small hole in the fire sleeve and pass the transducer wires through it. Seal

with High temperature Silicone RTV sealant.

5.

Before connecting fuel hose to the carburetor , verify that the boost pump delivers at least

125% of takeoff fuel consumption at minimum fuel pressure as marked on fuel pressure gage.

J.P.INSTRUMENTS

PO Box 7033

Huntington Beach CA 92646

Title

: Installation of a Fuel Flow Transducer in the fuel line

from the fuel pump to the carburetor or fuel servo.

Drawing No.

700921

Date

02/14/97

Drawn

Approved

Rev NC

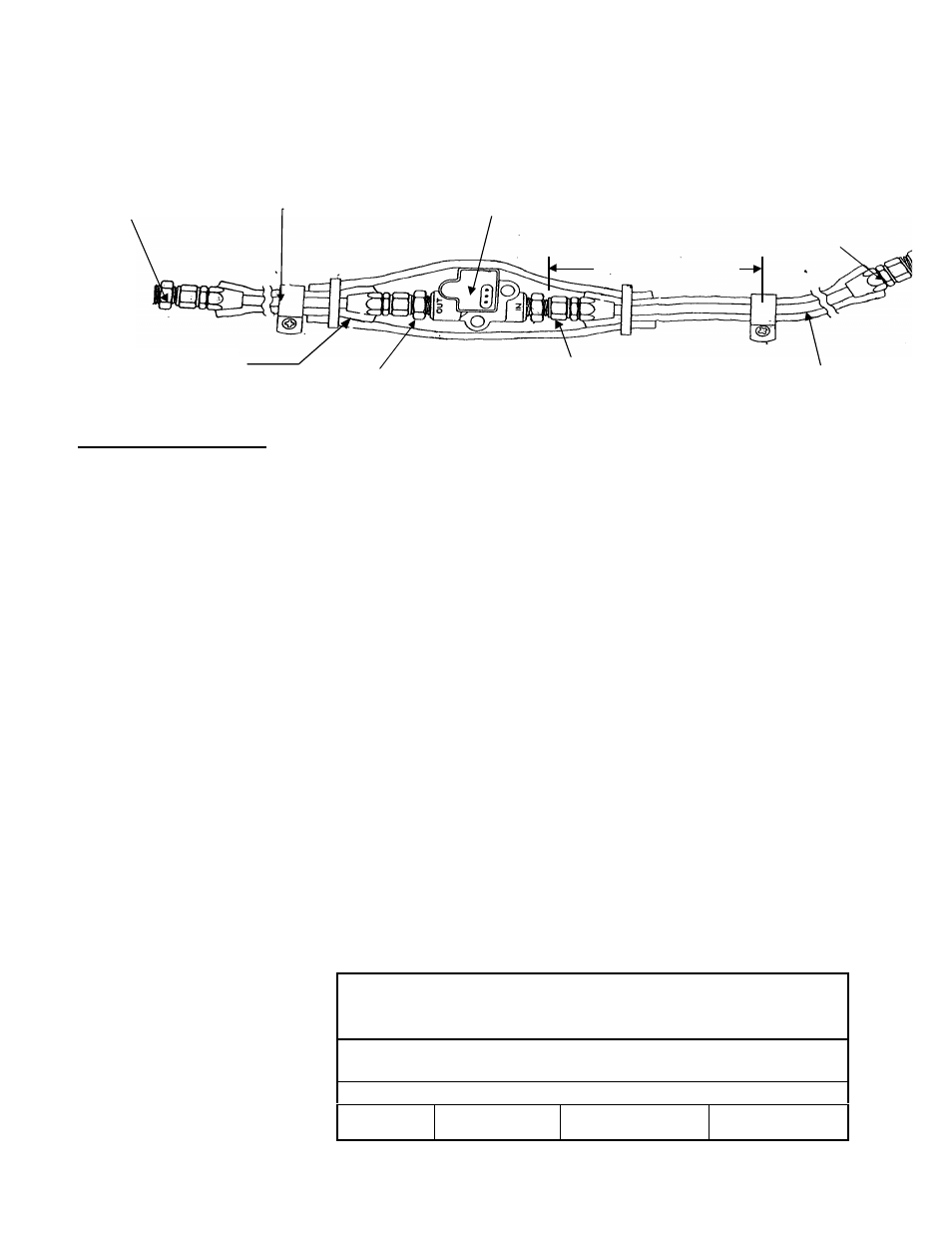

Fuel injector

Existing Fitting

TRANSDUCER

To Engine Driven

Fuel Pump Existing

8" max

from support

Aeroquip Fire Sleeve

AE102/624-24

2-AN816- Pipe to

Flare fitting. Do not

use aluminum fittings

New 303Aeroquip

hose

MS21919

Clamp as

required

Aeroquip

900591B

Clamp