Mueller Roll-Up Door C250 User Manual

Page 4

4

877-2-MUELLER

DO NOT CUT BANDS OR WRAPPING UNTIL INSTRUCTED.

A

Check wall opening width and height and verify these

measurements against size of door to be installed.

B

Verify that jambs are plumb.

C

Check floor and header for level.

D

Check for adequate side clearance at jambs and

clearance above and at sides of header. See

Clearance charts for minimum requirements.

E

Verify that the guide mounting surface on the jamb is flush.

F

Make sure all parts required for installation are

with the door; see parts list in hardware box.

G

Required tools

a. Tape measure

b. Electric drill, 1/2 inch

c. Drill bits, 3/8 inch

d. 3/8 inch nut setter

e. 1/2 inch drive socket set

f. Adjustable wrench

g. Leveling device; water or laser level recommended

h. Pocket / utility knife

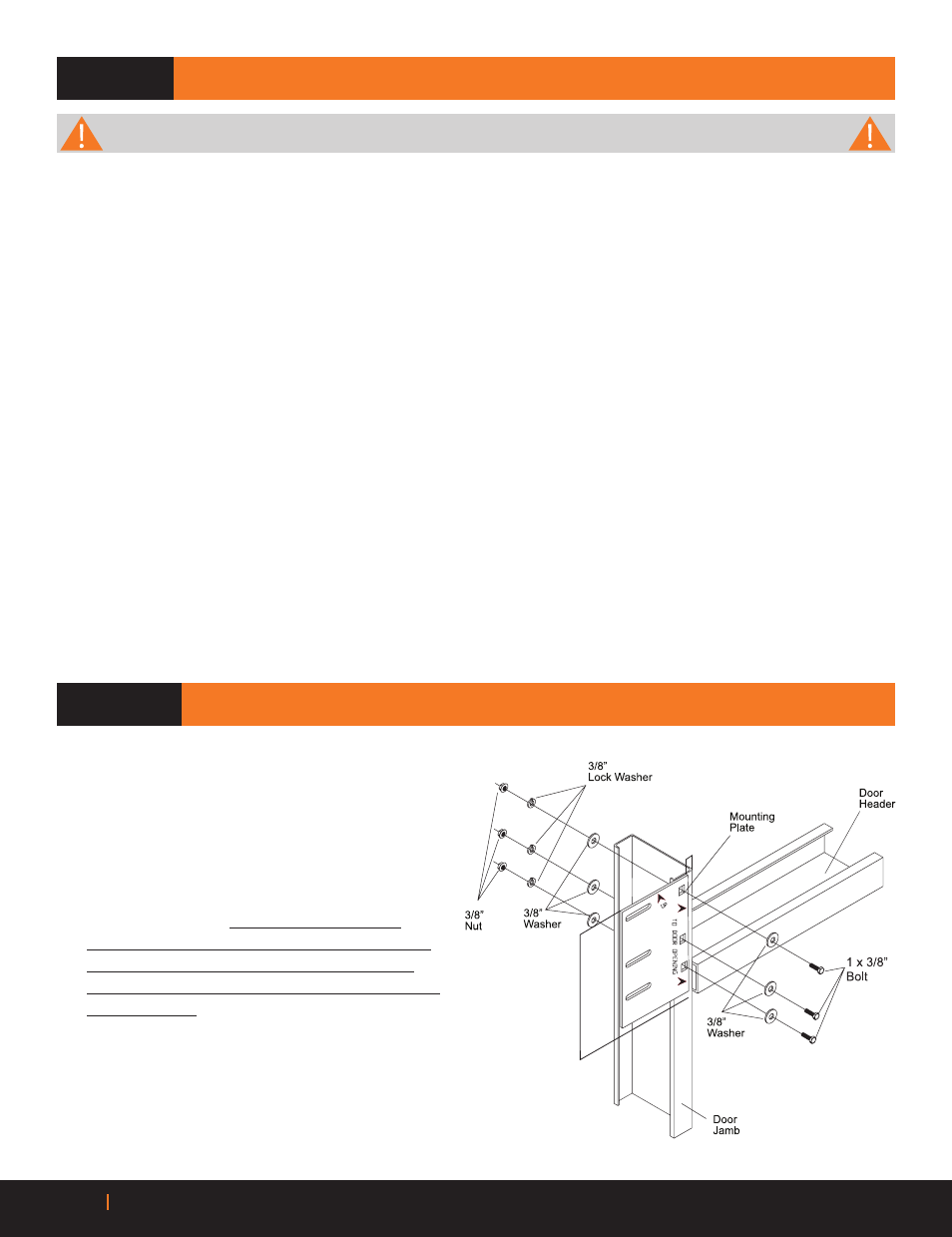

STEP 2: MOUNTING PLATES

A

If the door will be installed to steel jambs, mounting

plates for the door mounting plates are required and

may be welded or bolted to the jambs.

B

Top of mounting plates should be located approximately

10 inches above the top of the door opening. The inside

edge of mounting plate should be 1 1/2” from the inside

of the door jamb. (Note: direction of arrows

on mounting plates.) This is the most important

step; mounting plates MUST be level to each other;

checking via laser or water level is recommended,

do not go by relationship to door header; door header

may not be level.

STEP 1: WALL OPENING

1”

10”

Note: Minimum door jamb size of 8” x 3.5” 14 gauge,

grade 55 is required to support Roll Up Doors