Troubleshooting – Fast & Fluid TM300 User Manual

Page 14

Troubleshooting

Before calling your supplier or the service department, please check if you can solve the problem yourself.

If that does not work, you can call the service department for advice. Have the serial number and

dispenser type ready (these can be found on the silver CE sticker at the behind the service panel at the

front of the machine).

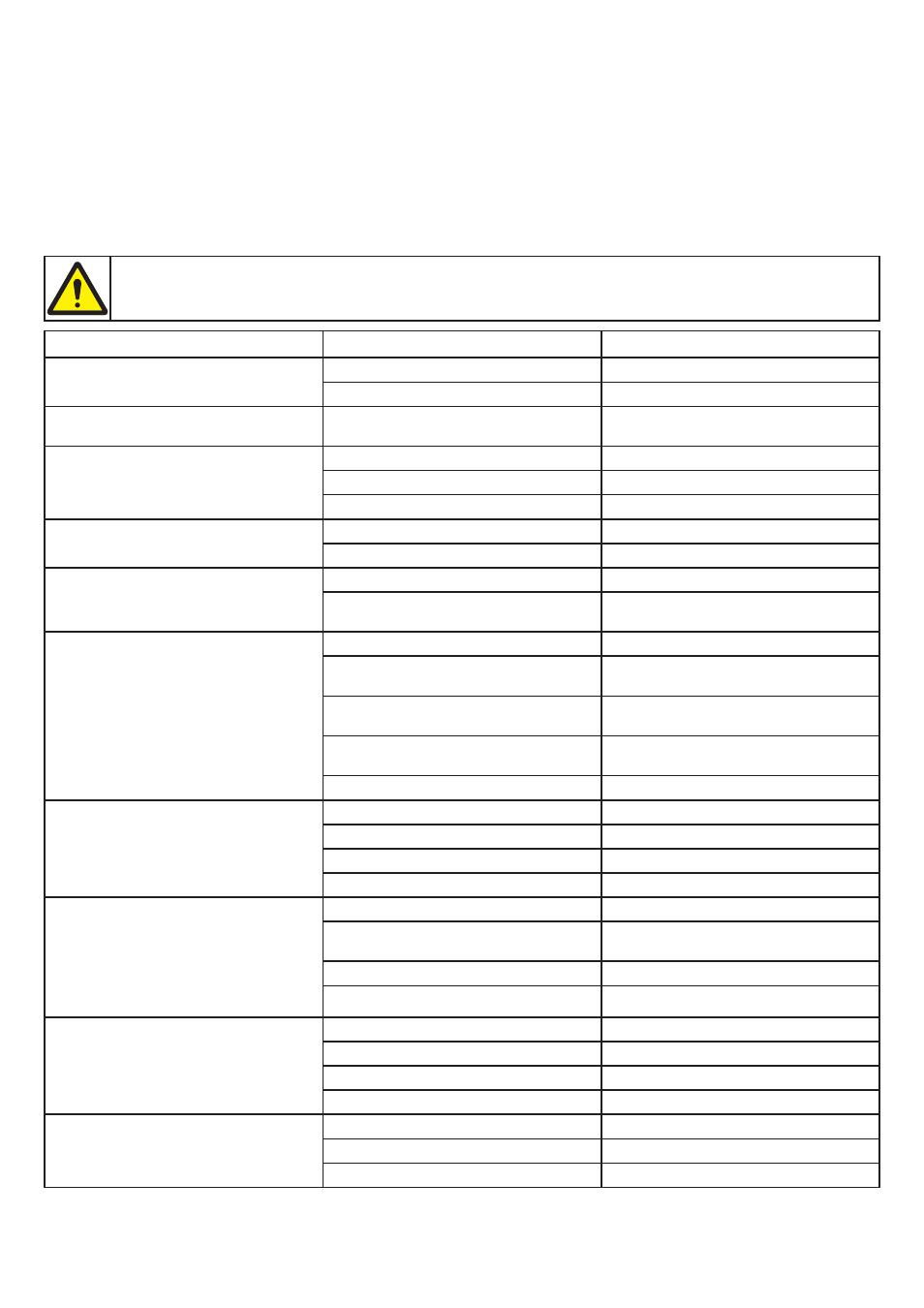

Use the table below to determine whether you can solve a problem yourself or if you need to call the

service department. You should never remove side panels from the dispenser, only certifi ed personnel are

allowed to do this. This table does not contain any error codes from the dispense software; please consult

the software manual for these.

Caution! MOVING PARTS CAN CAUSE INJURY. Always switch off the power (e.g. with

the emergency stop) before approaching moving parts.

Symptom

Cause

Action

Valve leaks through the outlet

opening

Air bubble in pump

Prime the pump

Valve is defective

Replace pump “Service”

Canister connection leaks around

the suction point

Worn O-ring(s)

Replace O-ring(s) “Service”

Air is being fed together with

the paste

Air bubble in the pump

Prime the pump

Canister is empty

Refi ll canister

Piston is defective

Replace pump “Service”

(New) software is not working

Program not correctly booted

Reboot computer & software

Software incorrectly installed

Reinstall software

No power from power unit

Not connected to power grid

Check power cables

Fuse blown

Remove plug from socket,

replace fuse

Colours are diffi cult to

reproduce

Mechanisms are dirty

Clean and oil

Quality fl uctuations in paste

supplied

Contact paste supplier

One or more pastes have

thickened

Replace paste(s)

Turntable in wrong position

Reset (press and unlock

emergency stop button)

Leaks around piston(s)

Replace piston(s) “Service”

Poor monitor picture, or no

picture

Monitor is switched off

Switch monitor on

Loose cable(s)

Check cables

Picture set too dark

Adjust picture correctly

Monitor malfunctioning

“Service”

Keyboard is not working

Loose cable(s)

Check cables

Windows Regional setting is

incorrect

Check Windows software manual

Defective cable(s)

“Service”

Keyboard is defective

“Service”

Stirrer is not rotating

Timer setting incorrect

Set the timer correctly (software)

Loose cable

Check cable

Defective cable

“Service”

Defective motor

“Service”

Turntable is not turning

Piston rod positioned too high

Set piston in lower position

Cable(s) loose

Check cables

Cable or motor defective

“Service”

14