Fast & Fluid Hercules Digital User Manual

Page 15

FAST & FLUID MANAGEMENT srl

A Unit of Idex Corporation

1155383H-it,en,es,fr,de

-

12/06/2008

15

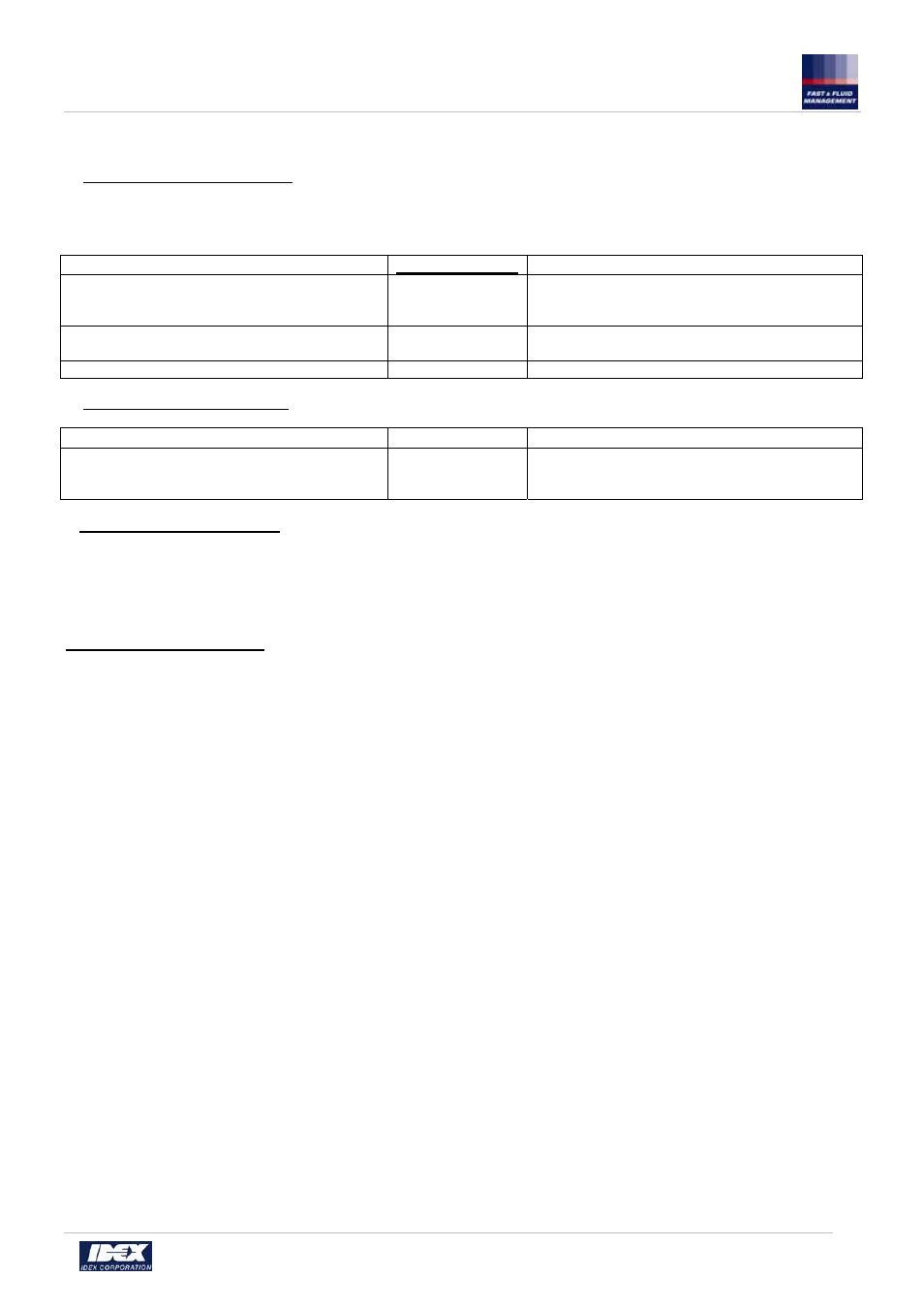

7. RESIDUAL RISK

1.

Residual risks list for the user

Even if all attentions have been considered during the projecting of the machine to guarantee a safety use it is possible to find

situations rationally foreseeable for which it has been possible only to reduce the risk but not to eliminate it completely

.

RISK DIRECTIVE

392

PRECAUTION

Injuries or crushing during loading and unloading

operations

1.6.4

4.1.1

Use security protective gloves and shoes during

loading and unloading

operations

Abrasions and injuries caused by sharp edges and

parts of the cans to use

1.6.4

4.1.1

Use protective gloves during loading and unloading

operations

Liquid leakages from the cans

Clean carefully the area where the operator works.

2. Residual risks for technicians

RISK DIRECTIVE

392

PRECAUTION

Danger of electrocution during the setting phases

of the inverter

1.5.1

1.5.2

Use security shoes.

Position protective screen for the dangerous

terminal blocks

3. Personal protection for user

If the equipment is used in a correct way , the machine following the production conditions , do not present

risks or dangers for the operator , which in any case has to wear individual protection devices

( security glasses , security against sliding shoes, protective gloves ) specially during the loading and unloading

phases of the cans.

4. General danger situations

There aren’t any particular danger situations ( E.G.. Fire risk, issue/ dispersion of dangerous products) but in any case it is

necessary to have a powder extinguisher for possible fire situations. (electrical equipments).

Security components and devices

The machine is equipped with the following security devices:

•

An emergency push button

•

A blocking door device

-> Emergency push button

For safety reasons, all users should know the position and the way to use the red emergency push button.

The emergency

RED

push button is assembled on the operator panel on the right part of the front panel. Pressing this button

causes the immediate opening of the keeping tension circuit and the stopping of the rotation motor. The starting of the normal

functioning of the equipment is possible by rotating the emergency push button clockwise and when the diagnostic signal on

the display disappears. In case of emergency stopping during the working cycle it is necessary execute the resetting procedures

by pushing

STOP KEY

.

-> Opening door sensor

The machine is equipped with a security device which doesn’t permit the starting of the cycle if the door is in loading position.

During the working cycle the security device doesn’t permit the opening of the door.

8. INSTALLATION CONDITIONS

Before installation please make sure of the following:

Place the Digital Hercules on a firm and leveled floor

•

220-240 VOLTAGE: Provide a clean, grounded outlet of 220 / 240 Volt (or otherwise specified following local situations),

which has a differential (MINIMUM 30mA), a magneto-thermic protection of 16 Amp.

•

115 VOLTAGE: Provide a clean, grounded outlet of 115 Volt (or otherwise specified following local situations), which has

a differential (MINIMUM 30mA), a magneto-thermic protection of 25 Amp. and a ground net following the rules.

Environmental conditions are within the following limits:

Ambient air temperature :

10 to 40 °C

Relative humidity

:

30 to 90 %

During the installation it is advisable to use protective gloves to avoid hand injuries