Filter – L.B. White I-3 Infraconic User Manual

Page 9

8

11.

Check all connections for gas leaks using approved

gas leak detectors. Gas leak testing is performed as

follows:

-- Check all pipe connections, hose connections,

fittings and adapters upstream of the gas

control with approved gas leak detectors.

-- In the event a gas leak is detected, check the

components involved for cleanliness and

proper application of pipe compound before

further tightening.

-- Tighten the gas connections as necessary to

stop the leak.

-- After all connections are checked and any

leaks are eliminated, light the heater.

-- Stand clear while the heater ignites to prevent

injury caused from hidden leaks that could

cause flashback.

-- W i t h t h e h e a te r i n o p e r a t i o n , c h e c k a l l

connections, hose connections, fittings and

joints as well as the gas control valve inlet and

outlet connections with approved gas leak

detectors.

-- If a leak is detected, check the components

involved for cleanliness in the thread areas

and proper application of pipe compound

before further tightening.

-- Tighten the gas connection as necessary to

stop the leak.

-- If necessary, replace the parts or components

involved if the leak cannot be stopped.

-- Ensure all gas leaks have been identified and

repaired before proceeding.

12.

A qualified service agency must check for proper

operating gas pressures upon installation of the

heaters.

13.

Use the proper gas supply line to assure proper

functioning of the heaters. Typically, 3/4 in. ID black

iron pipe is used to supply gas to the inlet of the zone

control panel with 1/2 in. ID black iron pipe used to

convey the gas to the heaters. However, always

consult your fuel gas supplier, or the L. B. White Co.,

Inc. for proper line sizing and installation.

14.

The heater is designed for either propane vapor with-

drawal or natural gas, depending on model number.

Do not use this heater in an propane liquid

withdrawal system. Do not permit propane in liquid

form to enter the heater at any time.

15.

T h e c o r ro s i ve a t m o s p h e r e p r e s e n t i n a n i m a l

confinement buildings can cause component failure

or heater malfunction. The heater should be

periodically inspected and cleaned in accordance

with the Maintenance and Cleaning Instructions in

this manual. Make sure that livestock is protected by

a back up alarm system that limits high and low

temperatures and also activates appropriate alarms.

16.

Ta ke t i m e to u n d e r s t a n d h ow to o p e r a te a n d

maintain the heater using this Owner’s Manual.

Make sure you know how to shut off the gas supply to

the building and to the individual heaters. Contact

your gas supplier if you have any questions.

17.

Any defects found in performing any of the service

procedures must be eliminated and defective parts

replaced immediately. Retest the heater before

placing it back into service.

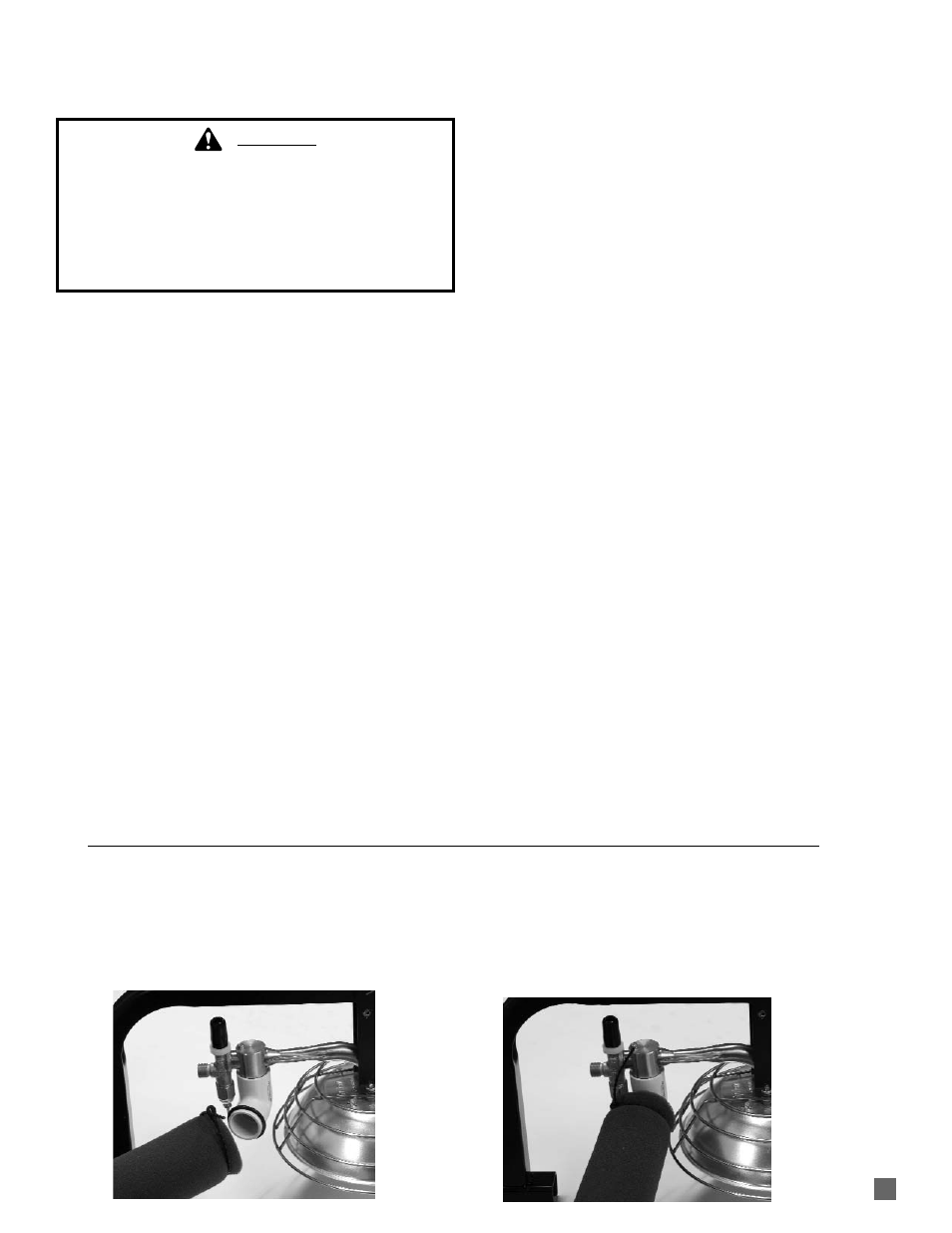

FILTER

1.

See Fig. 2 for attaching filter to heater.

A. Push filter completely onto air intake.

B. Attach filter to intake by using beaded cable tie.

Ensure cable tie securely fastens filter to air intake

of heater

2.

The filter may be removed by loosening the beaded

cable tie.

FIG. 2

WARNING

Fire and Explosion Hazard

■

Do not use open flame (matches, torches, candles,

etc.) in checking for gas leaks.

■

Use only approved leak detectors.

■

Failure to follow this warning can lead to fires or

explosions.

■

Fires or explosions can lead to property damage,

personal injury or death.