Heater control and operation – L.B. White I-3 Infraconic User Manual

Page 12

Proper temperature management is needed when using the I-3

radiant heater. The creep area, which is the comfort zone for

piglets, is managed independently from the room temperature.

The room’s temperature will be lower than the temperature

needed for the creep area. Lower room temperatures create two

benefits:

-- Less fuel/energy consumption

-- Increased sow feed intake which creates higher

weaned weights.

Managing the heat in this manner provides proper growing

environment for piglets, allowing them to keep warm without

heating the sow.

Temperature Management

I-3 modulating heaters heaters are normally operated and

controlled by the use of a non- electric zone control panel.

Contact the L.B.White Co.if you are considering connecting I-3

modulating heaters to a building controller.

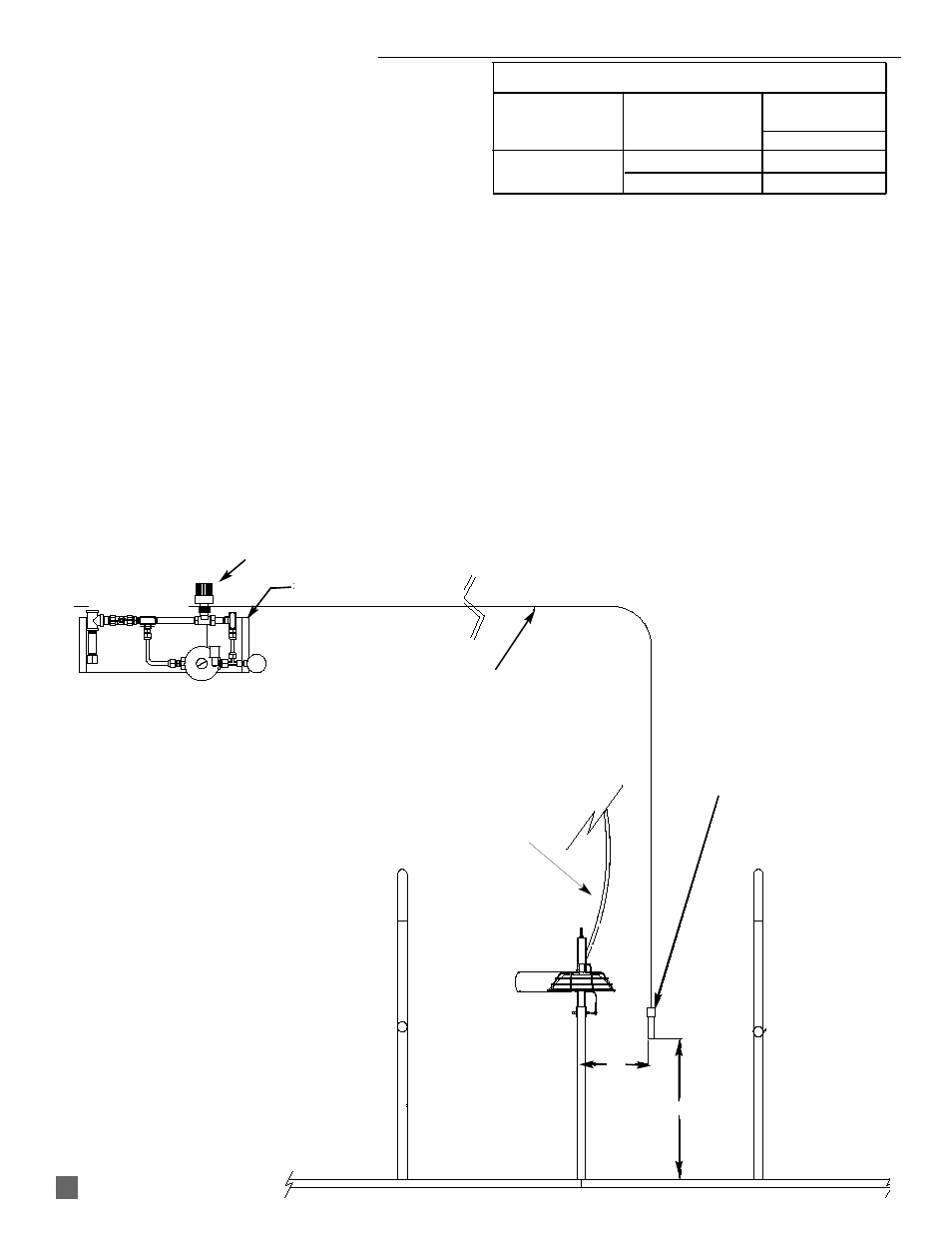

Zone Control Panel (See Fig.12)

The zone control panel is a non-electric, modulating design for

stand alone heater operation, and controls the following quantity

of heaters depending on fuel type.

The zone panel is a “heat- to- demand” operation system. It will

operate all I-3 heaters between 10% to 100% to satisfy the

temperature requirements established by the zone panel’s

thermostatic head.

The zone control panel must be mounted to a flat, stable wall

inside the building. Use lag screws provided. Ensure that the

thermostatic control module is not exposed to outside air

temperatures. Exposure of the thermostatic control module to

outside air temperatures may cause the heater to provide

unwanted heat.

Refer to Fig.12 for location of zone panel’s sensor. The sensor

must be located within a middle crate of a row of crates,

representing the average condition of the room. Do not locate the

sensor in a crate at the end of a row, or where could be

influenced by things such as cooler inlet ventilation air, exhaust

fans, opening of doors, etc.

CAPILLARY

DIVIDER

PANEL

18 IN.

CRATE

CRATE

SENSOR 8 IN. FROM

SIDE OF PANEL AND 18

IN. FROM PEN DECK

GAS HOSE TO

GAS SUPPLY

8 IN.

HEATER CONTROL and OPERATION

Modulating System

Medium

Model and

Capacity

Heat Output

Fuel

Panel

Quantity

I3

L. P. Gas

83

(2,800 BTUH)

Natural Gas

48

FIG. 12

11

ZONE PANEL

THERMOSTATIC HEAD