Bryant 393AAV User Manual

Page 5

(5.) Repeat foregoing procedures until each cell in

furnace has been cleaned.

(6.) Using vacuum cleaner, remove residue from each

cell.

(7.) Using vacuum cleaner with soft brush attachment,

clean burner assembly.

(8.) Reinstall cell inlet plates and burner assembly. Care

must be exercised to center burners in cell openings.

10. Clean flame sensor with fine steel wool

11. Remove old sealant from center panel and collector box

flange and apply new sealant to collector box flange and

reinstall on center panel, making sure all 8 screws are

secure.

NOTE:

A releasing agent such as PAM cooking spray or equiva-

lent (must not contain corn or canola oil, aromatic or halogenated

hydrocarbons or inadequate seal may occur) and RTV sealant

(G.E. 162, 6702, or Dow-Corning 738) are needed before starting

installation. DO NOT substitute any other type of RTV sealant.

G.E. 162 (P771-9003) is available through RCD in 3-oz tubes.

12. Reinstall relief box and inducer assembly.

NOTE:

If inducer assembly gasket is damaged, use RTV sealant

to seal inducer assembly to collector box.

NOTE:

A releasing agent such as PAM cooking spray or equiva-

lent (must not contain corn or canola oil, aromatic or halogenated

hydrocarbons or inadequate seal may occur) and RTV sealant

(G.E. 162, 6702, or Dow-Corning 738) are needed before starting

installation. DO NOT substitute any other type of RTV sealant.

G.E. 162 (P771-9003) is available through RCD in 3-oz tubes.

13. Reconnect wires to the following components:

a. Blocked vent safeguard switch.

b. Inducer motor.

c. Pressure switch.

d. Limit overtemperature switch(es).

e. Gas valve.

f. Hot surface ignitor.

g. Flame-sensing electrode

h. Flame rollout switch(es), if applicable.

14. Reinstall vent connector to furnace flue collar. After fully

assembling vent connector to furnace flue collar, securely

fasten vent connector to flue collar with 2 field-supplied,

corrosion-resistant, sheet metal screws located 180 degrees

apart and midway up the collar.

15. Turn electrical power and gas to ON.

16. Set thermostat and check furnace for proper operation.

17. Verify blower airflow and speed changes between heating

and cooling.

18. Check for gas leaks.

WARNING:

Never use a match or other open flame to

check for gas leaks. Use a soap-and-water solution. A

failure to follow this warning could result in fire, personal

injury, or death.

19. Replace control access door.

IV.

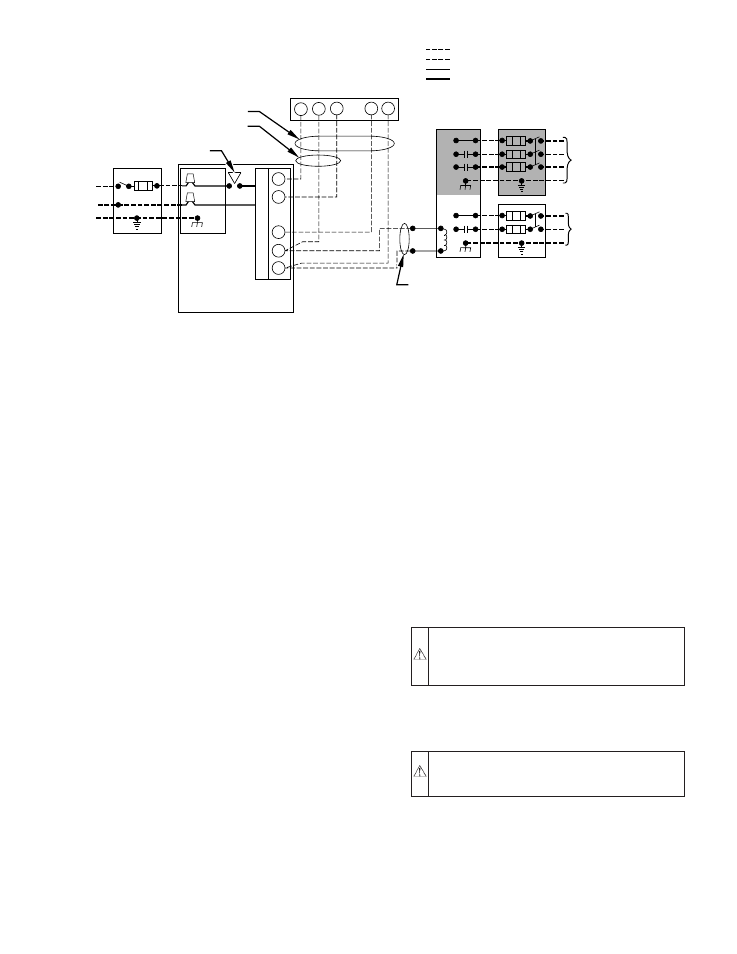

ELECTRICAL CONTROLS AND WIRING

CAUTION:

There may be more than 1 electrical supply

to the unit. Check accessories and cooling the unit for

additional electrical supplies.

The electrical ground and polarity for 115-v wiring must be

maintained properly. Refer to Fig. 5 for field wiring information

and to Fig. 7 for furnace wiring information.

NOTE:

If the polarity is not correct, the STATUS LED on the

control will flash rapidly and prevent the furnace from heating.

The control system also requires an earth ground for proper

operation of the control and flame-sensing electrode.

Fig. 5–Heating and Cooling Application Wiring Diagram

A98521

115-V FIELD-

SUPPLIED

DISCONNECT

AUXILIARY

J-BOX

24-V

TERMINAL

BLOCK

THREE-WIRE

HEATING-ONLY

FIVE WIRE

NOTE 1

NOTE 2

FIELD-SUPPLIED

DISCONNECT

CONDENSING

UNIT

TWO

WIRE

FURNACE

C

O

N

T

R

O

L

R

G

C

W

C

R

G

Y

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

BLOWER DOOR SWITCH

WHT

BLK

WHT

BLK

NOTES:

Connect Y-terminal in furnace as shown for proper blower operation.

Some thermostats require a "C" terminal connection as shown.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

W

Y

GND

THERMOSTAT

TERMINALS

1.

2.

3.

—5—