Bryant 393AAV User Manual

Page 3

b. Remove filter cabinet door.

c. Slide filter out of cabinet.

d. If equipped with permanent, washable filter, clean filter

by spraying cold tap water through filter in opposite

direction of airflow. Rinse filter and let dry. Oiling or

coating of the filter is not recommended.

e. If equipped with factory-specified disposable media

filter, replace only with media filter having the same part

number and size.

f. Slide filter into cabinet.

g. Replace filter cabinet door.

h. Turn on electrical supply to furnace.

2. Filters installed in side(s) and/or bottom of blower compart-

ment (See Fig. 2)

a. Disconnect electrical power before removing access

doors.

b. Remove blower and control access doors.

c. Release filter retainer from clip at front of furnace

casing. (See Fig. 2.) For side return, clips may be used on

either or both sides of the furnace.

d. Slide filter(s) out.

e. Furnaces are equipped with permanent, washable filters.

Clean filters with tap water. Spray water through filter in

opposite direction of airflow.

f. Rinse and let dry. Oiling or coating of filter is NOT

recommended or required.

g. Reinstall filter(s)

h. Replace blower and control access doors

i. Restore electrical power to furnace.

II.

BLOWER MOTOR AND WHEEL

The following items should be performed by a qualified service

technician:

To ensure long life, economy, and high efficiency, clean accumu-

lated dirt and grease from blower wheel and motor annually.

The inducer and blower motors are pre-lubricated and require no

additional lubrication. These motors can be identified by the

absence of oil ports on each end of the motor.

Clean blower motor and wheel as follows:

1. Turn off electrical supply to furnace.

2. Remove control and blower access door.

3. Disconnect blower leads from furnace control. Notice wire

color and location for reassembly.

All other factory wires can be left connected, but field

thermostat connections may need to be disconnected de-

pending on their length and routing.

4. Remove 2 screws securing control and transformer support

to furnace.

5. Hang control and transformer support to side of furnace

casing.

6. Remove screws holding blower assembly to blower deck

and slide blower assembly out of furnace.

7. Clean blower wheel and motor using a vacuum with soft

brush attachment. Do not remove or disturb balance weights

(clips) on blower wheel blades. The blower wheel should

not be dropped or bent as balance will be affected.

8. If a greasy residue is present on blower wheel, remove

wheel from the blower housing and wash it with an

appropriate degreaser. To remove wheel:

a. Mark blower wheel location on shaft before disassembly

to ensure proper reassembly.

b. Loosen setscrew holding blower wheel on motor shaft.

NOTE:

Mark blower mounting arms, motor, and blower housing

so motor and each arm is positioned at the same location during

reassembly.

c. Mark blower wheel orientation and cutoff plate location

to ensure proper reassembly.

d. Remove screws securing cutoff plate and remove cutoff

plate from housing.

e. Remove bolts holding motor and motor mounts to

blower housing and slide motor and mounts out of

housing. Disconnect capacitor and ground wire attached

to blower housing before removing motor. Motor mount

belly band need not be removed unless motor is to be

replaced.

f. Remove blower wheel from housing.

CAUTION:

The blower wheel should not be dropped or

bend as balance will be affected.

9. Reassemble motor and blower by reversing items 9a

through 9f. Be sure to reattach ground wire.

10. Reinstall blower assembly in furnace.

11. Reinstall control and transformer support assembly in

furnace.

12. Reconnect blower leads to furnace control.

Refer to furnace wiring diagram (See Fig. 7), and connect

thermostat leads if previously disconnected.

NOTE:

Refer to Table 1 for motor speed lead relocation if leads

were not identified before disconnection

CAUTION:

Heating air speed selection MUST be ad-

justed to provide proper temperature rise as specified on

the rating plate. Failure to adjust the heating speed may

shorten heat exchanger life.

13. Turn on electrical supply. Manually close blower access

door switch. Use a piece of tape to hold switch closed.

Check for proper rotation and speed changes between

heating and cooling by jumpering R to W and then R to Y

on furnace control thermostat terminals.

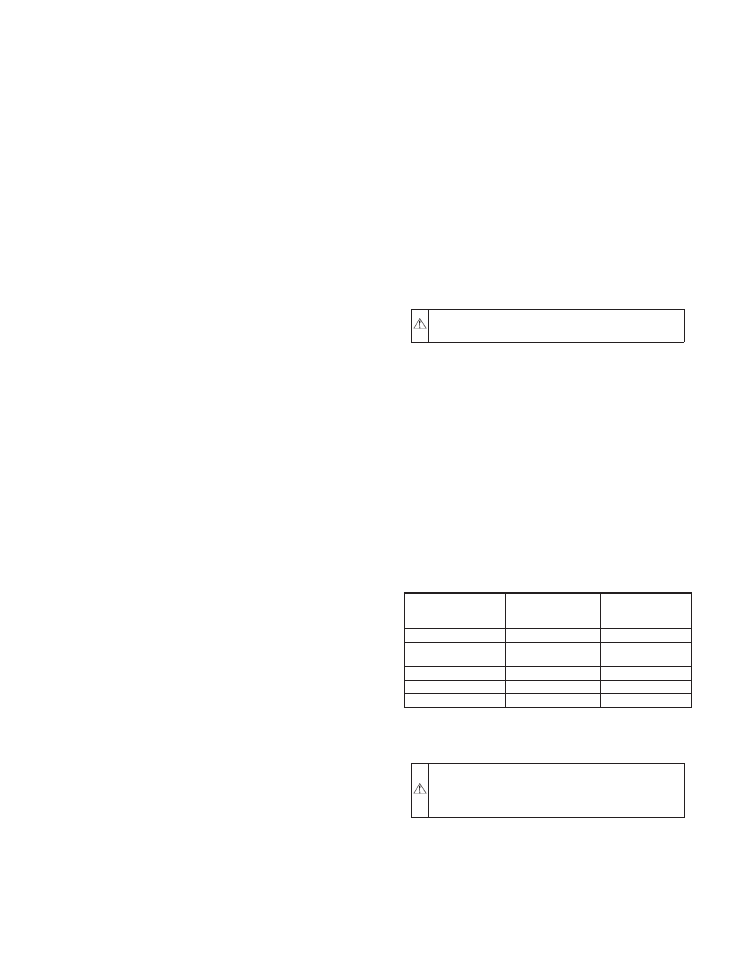

TABLE 1—SPEED SELECTOR

COLOR

SPEED

FACTORY-

ATTACHED

TO

Black

High

Cool

Yellow (When

Present)

Medium High

Spare

Blue

Medium Low

Heat

Red

Low

Spare

White

Common

L2/COM

—3—