Hardware torque values, Minimum hardware tightening torques – Buhler 2425 User Manual

Page 364

SECTION 5 - SPECIFICATIONS

5-34

HARDWARE TORQUE VALUES

Check the tightness of hardware periodically.

Use the following charts to determine the

correct torque when checking, adjusting or

replacing hardware on the tractor.

IMPORTANT: DO NOT use the values listed in

the charts if a different torque value or tightening

procedure is specified in this manual for a

specific application. Torque values listed are for

general use only.

Make sure fastener threads are clean and not

damaged

NOTE: A torque wrench is necessary to

properly tighten hardware.

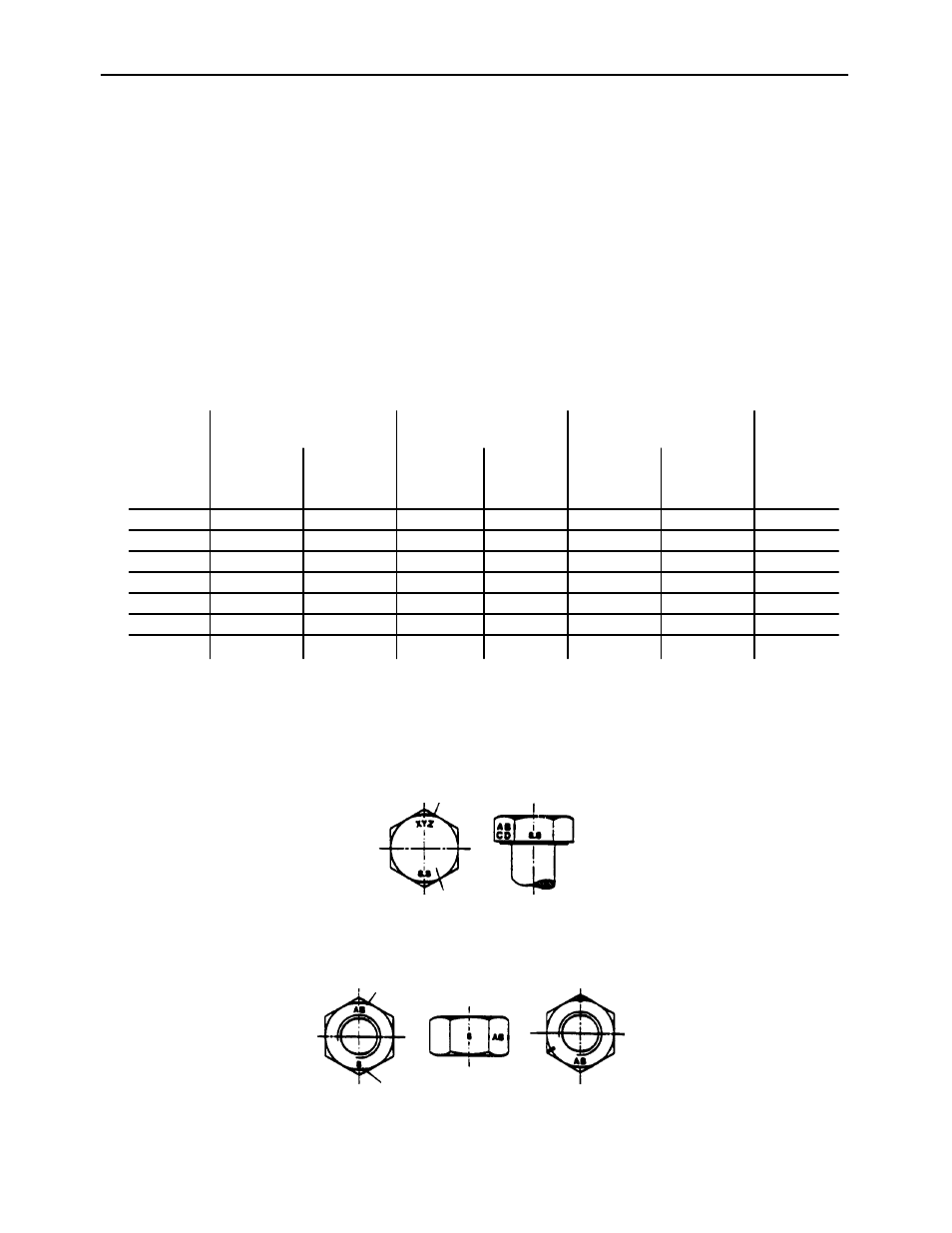

MINIMUM HARDWARE TIGHTENING TORQUES

IN FOOT POUNDS (NEWTON-METERS) FOR NORMAL ASSEMBLY APPLICATIONS

METRIC HARDWARE AND LOCKNUTS

M4

15* (1.7)

19* (2.2)

23* (2.6)

30* (3.4)

33* (3.7)

42* (4.8)

16* (1.8)

M6

51* (5.8)

67* (7.6)

79* (8.9)

102* (12)

115* (13)

150* (17)

56* (6.3)

M8

124* (14)

159* (18)

195*(22)

248* (28)

274* (31)

354* (40)

133* (15)

M10

21 (28)

27 (36)

32 (43)

41 (56)

45 (61)

58 (79)

22 (30)

M12

36 (49)

46 (63)

55 (75)

72 (97)

79 (107)

102 (138)

39 (53)

M16

89 (121)

117 (158)

137 (186)

177 (240)

196 (266)

254 (344)

97 (131)

M20

175 (237)

226 (307)

277 (375)

358 (485)

383 (519)

495 (671)

195 (265)

M24

303 (411)

392 (531)

478 (648)

619 (839)

662 (897)

855 (1160)

338 (458)

NOMINAL

SIZE

CLASS 5.8

CLASS 8.8

CLASS 10.9

LOCKNUT

CL.8

w/CL8.8

BOLT

UNPLATED

PLATED

w/ZnCr

UNPLATED

UNPLATED

PLATED

w/ZnCr

PLATED

w/ZnCr

NOTE: Torque values shown with * are inch pounds.

IDENTIFICATION

HEX CAP SCREWS AND CARRIAGE BOLTS

CLASSES 5.6 AND UP.

MANUFACTURER’S IDENTIFICATION

PROPERTY CLASS

HEX NUTS AND LOCKNUTS

CLASSES 05 AND UP.

MANUFACTURER’S IDENTIFICATION

PROPERTY CLASS

CLOCK MARKING